Polyurethane broadband sound absorption layer for underground acoustic waves

A technology of sound-absorbing layer and polyurethane, which is applied in the direction of sound-emitting devices and instruments, can solve the problem of narrow sound-absorbing frequency band, achieve the effect of improving sound-absorbing frequency band, simplifying the process, and realizing high-efficiency mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

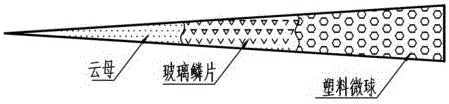

[0029] A polyurethane broadband sound-absorbing layer for sound waves in water, such as figure 1 As shown, the structure of the sound-absorbing layer is wedge-shaped or conical, and the sound-absorbing layer is an equidistant three-layer composite structure. The sound-absorbing layer is composed of a polyurethane matrix and a sound-absorbing filler embedded in the polyurethane matrix.

[0030] Among them, the weight percentage of each material that makes up the sound-absorbing layer is: polyurethane matrix 72%, sound-absorbing filler 28%; polyurethane matrix is composed of polymer polyol, diisocyanate, small molecule polyol and plasticizer, each material in polyurethane matrix The weight percentage of the total weight of the polyurethane matrix is: polyether polyol 22%, diisocyanate 30%, small molecule polyol 44% and plasticizer 4%. The density of the sound-absorbing layer is 1100kg / m 3 , the acoustic impedance of the sound-absorbing layer matches that of water. Under the s...

Embodiment 2

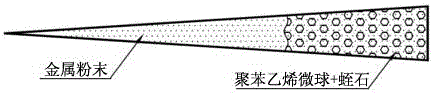

[0033] A polyurethane broadband sound-absorbing layer for sound waves in water, such as figure 2As shown, the structure of the sound-absorbing layer is wedge-shaped or conical, and the sound-absorbing layer is a non-equidistant two-layer composite structure. The sound-absorbing layer is composed of a polyurethane matrix and a sound-absorbing filler embedded in the polyurethane matrix.

[0034] Among them, the weight percentage of each material that makes up the sound-absorbing layer is: polyurethane matrix 80%, sound-absorbing filler 20%; polyurethane matrix is composed of polymer polyol, diisocyanate, small molecule polyol and plasticizer, each material in polyurethane matrix The percentage of the weight of the polyurethane matrix to the total weight of the polyurethane matrix is: polyether polyol 15%, diisocyanate 20%, small molecule polyol 61% and plasticizer 4%. The density of the sound-absorbing layer is 1000kg / m 3 , the acoustic impedance of the sound-absorbing layer...

Embodiment 3

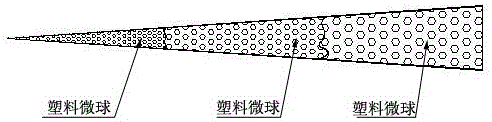

[0037] A polyurethane broadband sound-absorbing layer for sound waves in water, such as image 3 As shown, the structure of the sound-absorbing layer is wedge-shaped or conical, and the sound-absorbing layer is a non-equidistant three-layer composite structure. The sound-absorbing layer is composed of a polyurethane matrix and a sound-absorbing filler embedded in the polyurethane matrix.

[0038] Among them, the weight percentage of each material that makes up the sound-absorbing layer is: polyurethane matrix 50%, sound-absorbing filler 50%; polyurethane matrix is composed of polymer polyol, diisocyanate, small molecule polyol and plasticizer, each material in polyurethane matrix The percentage of the weight of the polyurethane matrix to the total weight of the polyurethane matrix is: polyether polyol 25%, diisocyanate 30%, small molecule polyol 35% and plasticizer 10%. The density of the sound-absorbing layer is 1500kg / m 3 , the acoustic impedance of the sound-absorbing la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com