A Combined Die and Its Application in Forming Composite Structural Parts

A technology of combining molds and composite materials, applied in the field of composite material molding, can solve the problems of high expansion pressure, multi-cavity side by side, and excessive cavity space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

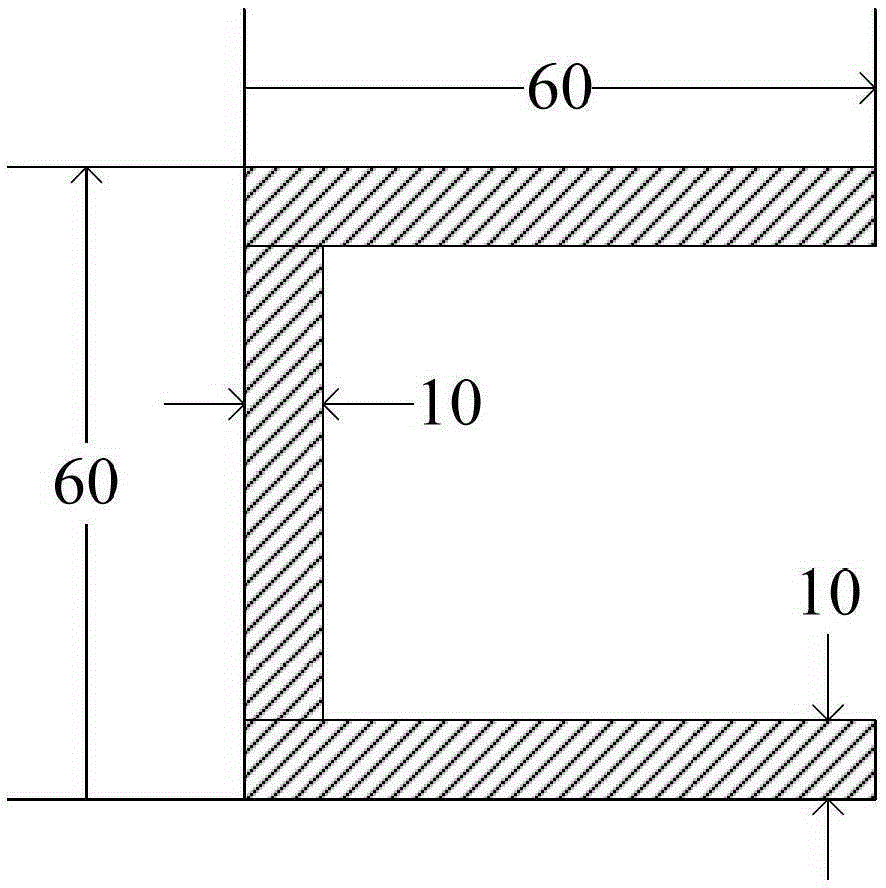

[0025] The cross-section of the product to be formed is inverted U-shaped, with a width of 60mm, a height of 60mm, and a thickness of 10mm; image 3 Shown:

[0026] 1) Make a silicone rubber / metal core combination soft mold that is consistent with the shape of the pressurized cavity of the product to be formed; make a closed metal female mold that is consistent with the shape of the product to be formed;

[0027] 2) Lay composite material on the outside of the soft mold made in step 1). After the layup is completed, put it into the closed metal female mold, and fix the metal core and the closed metal female mold with screws; heat, shape composite materials;

[0028] 3) Demoulding: first open the closed metal female mold, and then take the soft mold out of the cavity of the product to obtain the molded composite structural part.

[0029] The silicone rubber in the silicone rubber / metal core combined soft mold described in the above step 1) is an addition type room temperature...

Embodiment 2

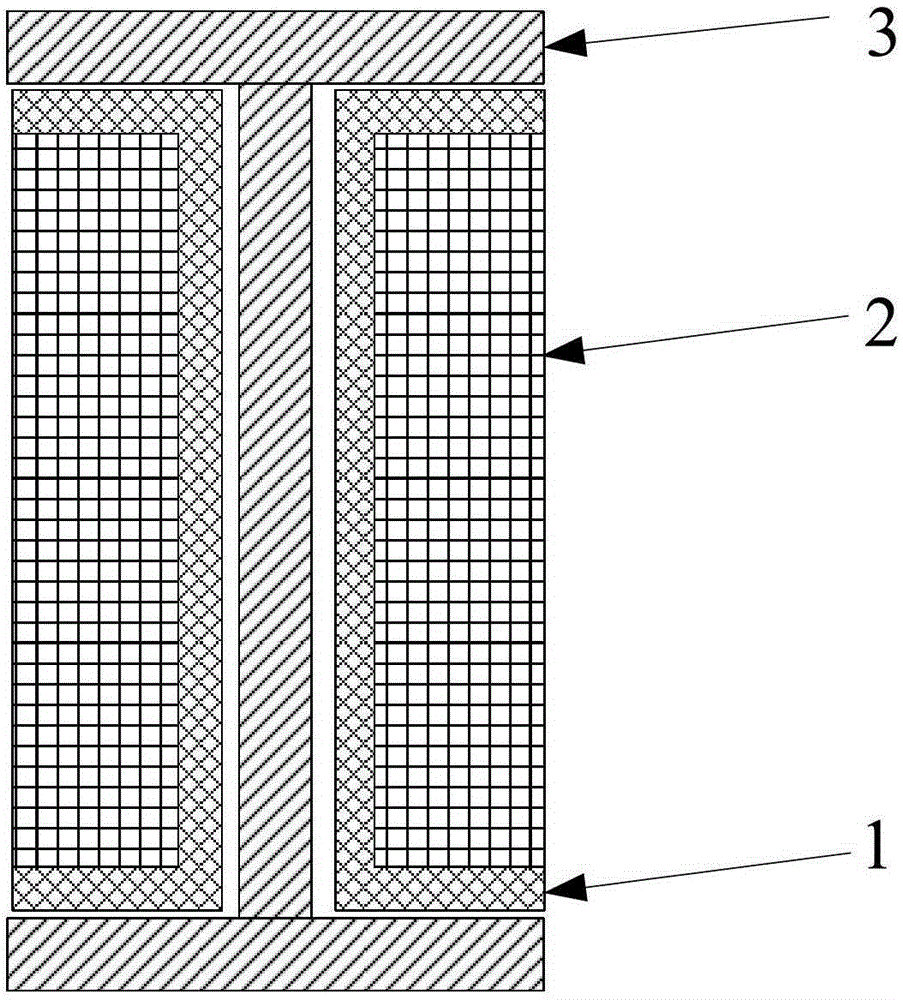

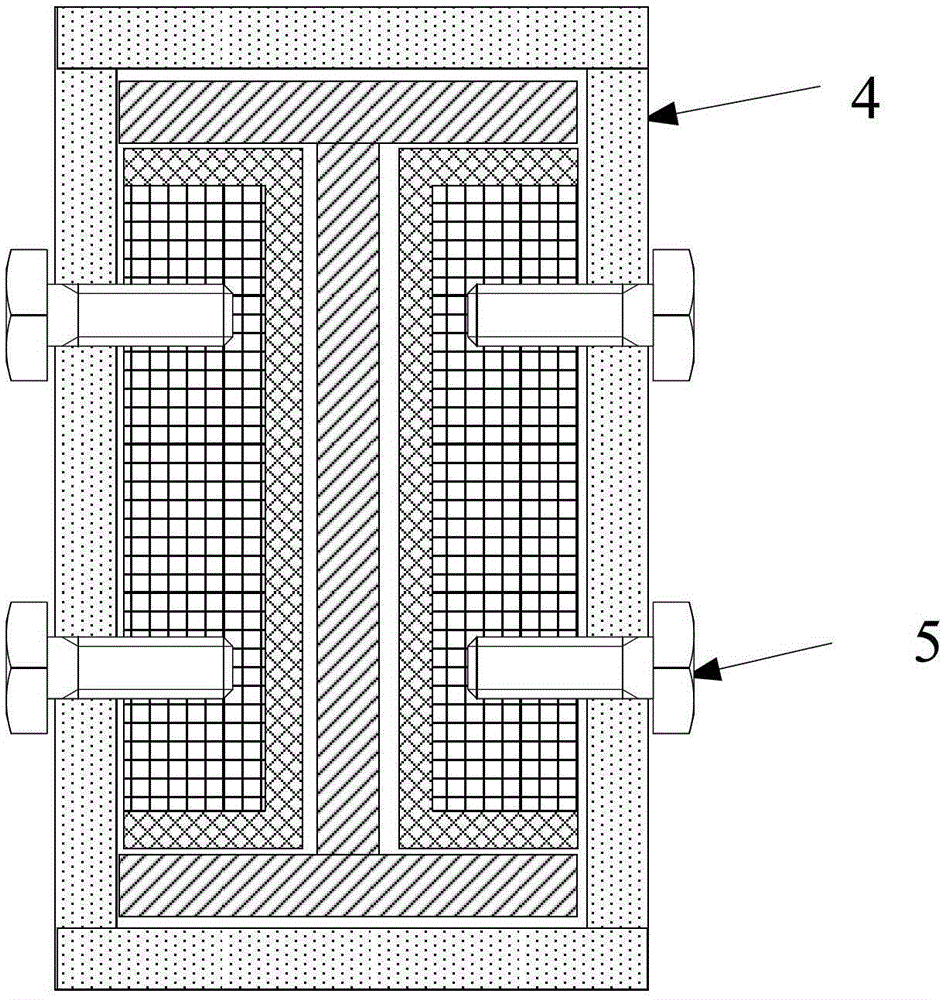

[0031] like figure 1 and figure 2 As shown, a combination mold includes a silicone rubber / metal core composite soft mold, a closed metal female mold 4 and a connector 5; the silicone rubber / metal core composite soft mold includes a silicone rubber 1 and a metal core 2 The periphery of the metal core 2 is silicone rubber 1, and the silicone rubber / metal core combined soft mold mold is installed in the cavity of the product 3 to be formed; the closed metal female mold 4 is located outside the product 3 to be formed; the closed metal female mold 4 and the metal core 2 are fixedly connected by screws 5;

[0032] The cross-section of the product to be formed is I-shaped, with a width of 60mm, a height of 60mm, and a thickness of 10mm; Figure 4 Shown:

[0033] 1) Make a silicone rubber / metal core combination soft mold that is consistent with the shape of the pressurized cavity of the product to be formed; make a closed metal female mold that is consistent with the shape of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com