Multi-level cyclone pipe type engineering machinery air filter

A technology of air filter and construction machinery, applied in the direction of combined air filter and muffler, mechanical equipment, intake muffler, etc., can solve problems such as difficulty in engineering promotion and application, complex structure, etc., and achieve optimal design structure shape, reduce airflow noise, and improve the effect of energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is described in detail below. The embodiment of the present invention is only for illustrating a specific structure, and the scale of the structure is not limited by the embodiment.

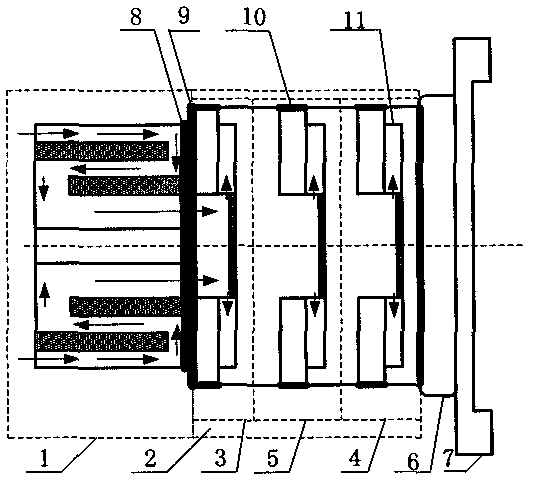

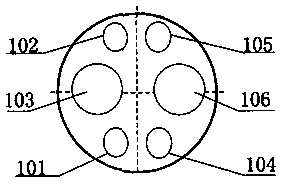

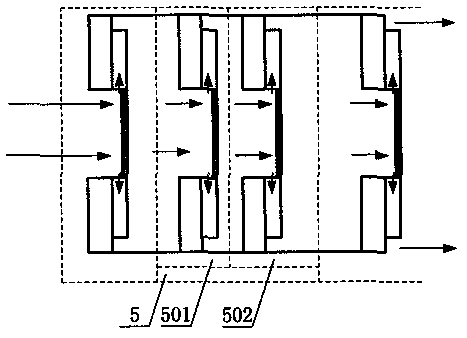

[0023] see figure 1 and figure 2 , a special air filter for multi-stage swirl tube construction machinery according to the present invention, comprising a multi-stage swirl tube air noise reduction device (1), a multi-stage filter (2) and a filter lower end cover (7) . Multi-stage swirl tube air noise reduction device (1), cylindrical structure, including the first return air intake pipe 101, the second return air intake pipe 102 and the first air outlet pipe 103 are arranged on the left half plane, the third return air intake pipe The pipe 104 , the fourth return air intake pipe 105 and the second air outlet pipe 106 are arranged on the right half plane to eliminate the mid-high frequency noise in the external inflow air. The first air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com