A kind of powdery gypsum for making polymer material products and its preparation method

A technology for polymer materials and gypsum, which is applied in the field of powder gypsum for making polymer material products and its preparation, can solve the problem of affecting the comprehensive utilization effect of natural gypsum or industrial by-product gypsum, and increasing the environmental pressure of gypsum waste residues. , adhesive properties, mechanical properties, compatibility and other issues are unstable, so as to improve comprehensive utilization, improve material compatibility, and improve mechanical properties and biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of powdery gypsum used to make polymer material products. Weigh 30kg of dihydrate desulfurized gypsum as raw material, dry it at a temperature of 100°C to constant weight, add 3kg of additives to Mixing, wherein, the proportion of additives by weight is: 7kg clay powder, 17kg fly ash, 9kg sodium polyacrylate, 9kg methylcellulose, and then sent to a mixer with a rotating speed of 300r / min for 5min, and then sent to into a high-pressure mill for grinding to obtain powdered gypsum.

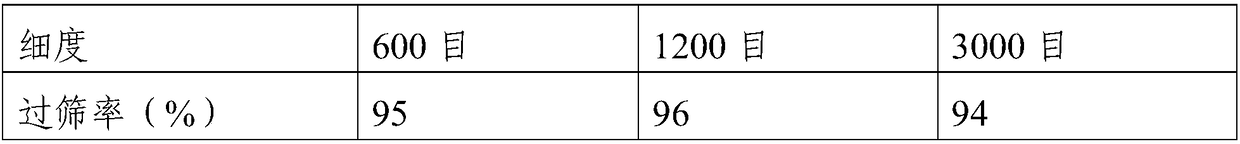

[0031] After testing, the powdery gypsum test results are shown in Table 1:

[0032] Table 1:

[0033] Fineness

Embodiment 2

[0035] A powdery gypsum used to make polymer material products. Weigh 30kg of α-state phosphogypsum as a raw material, dry it at a temperature of 60°C until it reaches a constant weight, and add 0.9kg of additives to dry it. Mixing, wherein, the proportion of additives by weight is: 11kg clay powder, 20kg fly ash, 7kg sodium polyacrylate, 6kg methylcellulose, and then sent to a mixer with a rotating speed of 500r / min for 8 minutes, and then sent to into a high-pressure mill for grinding to obtain powdered gypsum.

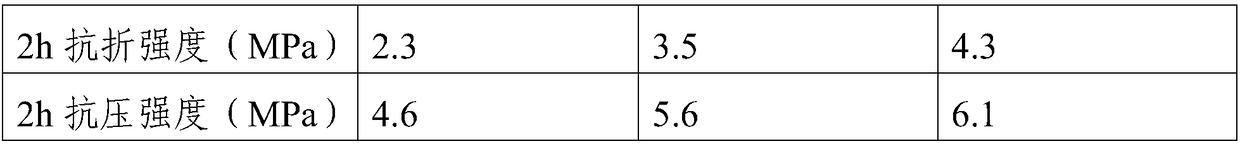

[0036] After testing, the powdery gypsum test results are shown in Table 2:

[0037] Table 2:

[0038]

[0039]

Embodiment 3

[0041] A kind of powdery gypsum used to make polymer material products. Weigh 30kg of natural gypsum in dihydrate state as raw material, dry it at a temperature of 40°C to constant weight, and add 1.5kg of additives Mixing, wherein, the auxiliary agent is in proportion by weight: 10kg clay powder, 9kg fly ash, 5kg sodium polyacrylate, 7kg methyl cellulose, then sent to the mixer with a rotating speed of 200r / min to stir for 8min, and then Send it to a high-pressure mill for grinding to obtain powdered gypsum.

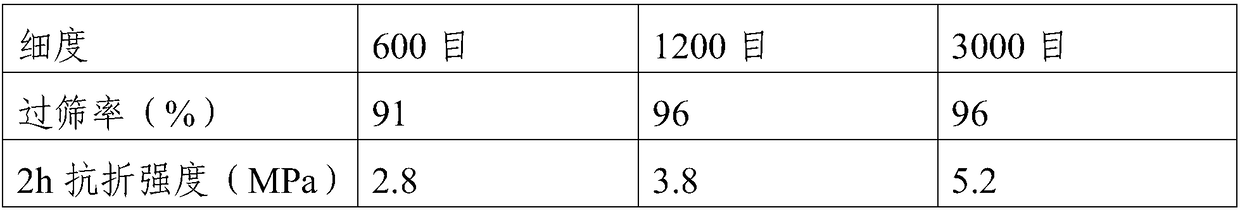

[0042] After testing, the powdery gypsum test results are shown in Table 3:

[0043] table 3:

[0044] Fineness

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com