A kind of fertilizer effect slow-release cement-based cementitious material and preparation method thereof

A gelling material, slow-release technology, applied in the fields of botanical equipment and methods, inorganic fertilizers, planting substrates, etc., can solve the problems of fertilizer efficiency loss, reduction of fertilizer efficiency utilization rate, and impact strength, etc., to reduce decomposition and volatilization, reduce Adverse effects, effects of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A fertilizer-effect slow-release cement-based cementitious material, which is composed of the following raw materials in parts by weight: 80.0 parts of low-alkalinity sulphoaluminate cement, 10.0 parts of performance adjustment components, 5.0 parts of potassium sulfate compound fertilizer, 4.0 parts of coagulation-adjusting components; among them, 5 parts of expanded vermiculite in performance-adjusting components, 5 parts of machine-made black charcoal, 0.08 parts of boric acid in coagulation-adjusting components, 3.92 parts of urea, sulfur in low-alkalinity sulphoaluminate cement 44 parts of aluminate cement clinker, 28 parts of anhydrite, and 8 parts of limestone.

[0029] The preparation method of the fertilizer effect slow-release cement-based cementitious material is prepared by the following steps:

[0030] (1) Put the performance adjustment components and nutritional components in a ball mill, mix and grind for 5 minutes, then cool for 10 minutes, test the siev...

Embodiment 2

[0035] A fertilizer-effect slow-release cement-based gelling material, which is composed of the following raw materials in parts by weight: 86.0 parts of low-alkalinity sulphoaluminate cement, 7.5 parts of performance adjustment components, 4.0 parts of nutritional components, and 4.0 parts of nutrient components. Divide into 2.5 servings. Among them, 4 parts of expanded vermiculite in the performance adjustment component, 3.5 parts of machine-made black charcoal, 0.25 part of boric acid in the setting adjustment component, and 2.25 parts of urea. 54 parts of sulphoaluminate cement clinker, 20 parts of anhydrite, and 12 parts of limestone in low-alkalinity sulphoaluminate cement.

[0036] The preparation method of the slow-release fertilizer-effect cement-based cementitious material is the same as that in Example 1.

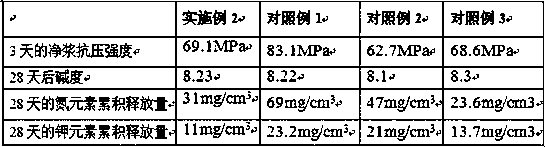

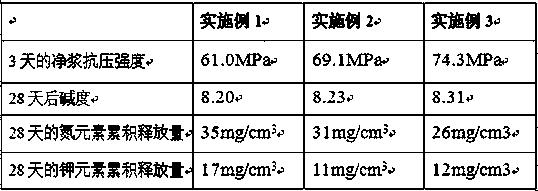

[0037] The performance test of the fertilizer-effect slow-release cement-based cementitious material prepared in this example is as follows: the compressive str...

Embodiment 3

[0039]A fertilizer-effect slow-release cement-based gelling material, which is composed of the following raw materials in parts by weight: 92.0 parts of low-alkalinity sulphoaluminate cement, 5.0 parts of performance adjustment components, 2.0 parts of nutritional components, and 2.0 parts of nutrient components. 1.0 points. Among them, 3.5 parts of expanded vermiculite in the performance adjustment component, 1.5 parts of machine-made black charcoal, 0.05 part of boric acid and 0.95 part of urea in the setting adjustment component. 52 parts of sulphoaluminate cement clinker, 27 parts of anhydrite, and 13 parts of limestone in low-alkalinity sulphoaluminate cement.

[0040] The preparation method of the slow-release fertilizer-effect cement-based cementitious material is the same as that in Example 1.

[0041] The performance test of the fertilizer-effect slow-release cement-based cementitious material prepared in this example is as follows: the compressive strength of the 3-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com