Compressing processor for waste zip-top cans

A technology of cans and processors, applied in the direction of presses, manufacturing tools, etc., can solve the problems of large quantity, large space occupied by cans, storage and transportation difficulties of waste cans, etc., and achieves the effects of reasonable design, simple structure and high recycling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

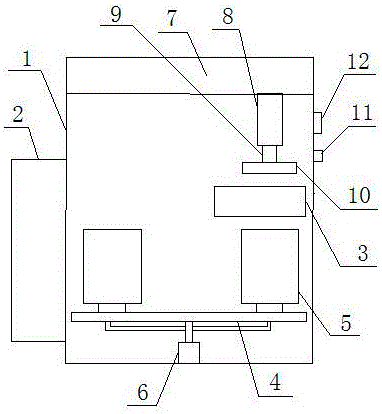

[0011] A kind of waste and used cans compression processing machine as shown in Figure 1, comprises outer box body 1, and one side of outer box body 1 is provided with discharge door 2, and outer box body 1 upper end is provided with feeding opening 3, and the outer box body 1 The bottom is provided with a rotatable turntable 4, and the radial edge of the turntable 4 is symmetrically provided with two inner boxes 5 with open upper ends and closed bottom ends, and the bottom of the outer box body 1 is provided with a motor 6 that drives the turntable 4 to rotate; A hydraulic station 7 is installed on the upper side of the box body 1, and a piston hydraulic cylinder 8 is installed at the bottom of the hydraulic station 7. A pressure hammer 10 is installed on the piston rod head 9 of the hydraulic cylinder 8, and the oil inlet and outlet of the hydraulic cylinder 8 pass through the The hydraulic oil pipe is connected with the oil inlet and outlet of the hydraulic station 7.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com