Preparation process of a flexible bullet-proof and stab-proof structure

A ballistic-proof and anti-stab technology and preparation technology, which is applied in the field of preparation technology and preparation technology of flexible bullet-proof and anti-stab structures, can solve the problems of limited application occasions, poor high temperature resistance, high material cost, etc., and achieve low production cost and long service life , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

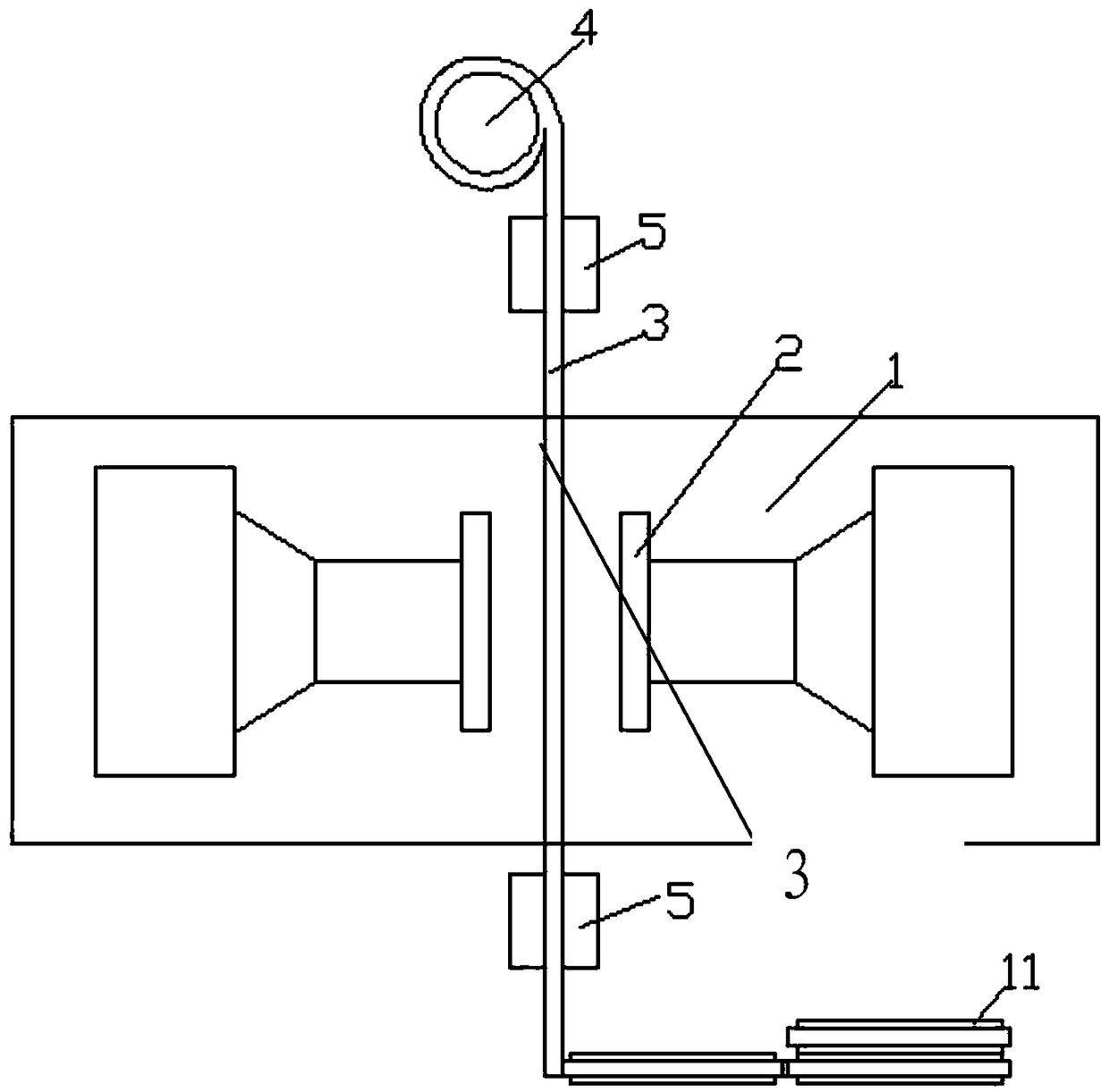

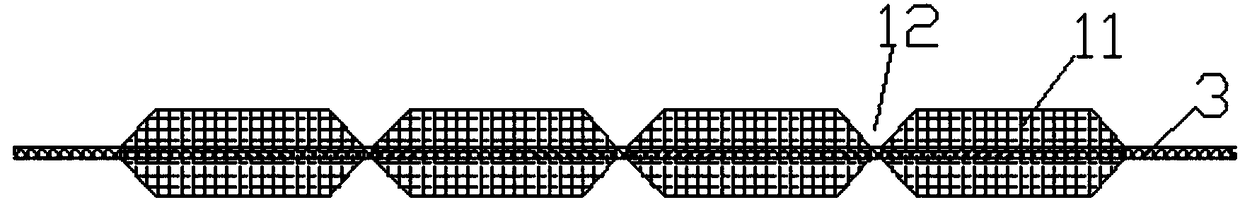

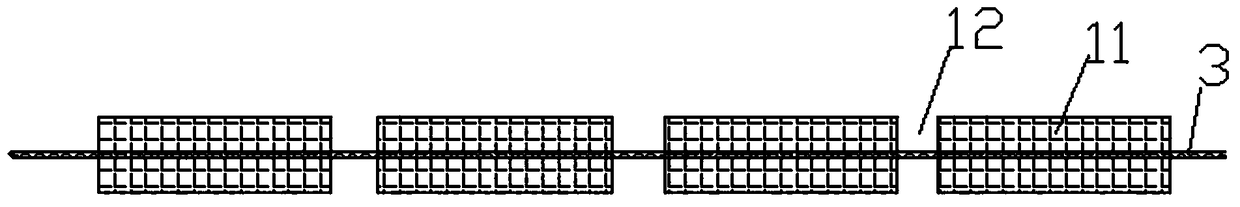

[0029] Embodiment one, as attached figure 1 Shown, the preparation technology of flexible bullet-proof stab-proof structure of the present invention, mass proportion is 75% polycarbonate, mass proportion is 20% glass fiber and auxiliary components such as a certain amount of fire retardant, toughening agent, color particle ( Content at 5%) after mixing and stirring, put into the injection molding machine 1. Among them, flame retardants, tougheners, color particles and other additives play a role in improving the performance and appearance of protective materials. Two groups of symmetrical injection molds 2 that can be injection molded at the same time are arranged at the opposite positions in the left and right directions on the injection molding machine 1 , and then the base cloth 3 is laid between the symmetrical injection molds 2 . The base fabric 3 is in the shape of a strip, one end is wound on the shrink tube 4, and the other end extends downwards, and then stretched by...

Embodiment 2

[0032] Embodiment 2, the preparation process of the flexible bullet-proof and stab-proof structure of the present invention, the mass specific gravity is respectively 65% nylon 66, mixed with the mass specific gravity of 35% carbon fiber short fiber, and then put into the injection molding machine 1. Two groups of symmetrical injection molds 2 that can be injection molded at the same time are arranged at the opposite positions in the left and right directions on the injection molding machine 1 , and then the base cloth 3 is laid between the symmetrical injection molds 2 . The base fabric is in the shape of a long strip, one end is wound on the shrink tube 4, and the other end extends downwards, and then it is stretched by the transmission mechanism 5, wherein the base fabric is a fabric made of interlaced carbon fiber and aramid fibers, and the weight of the material ranges from 200 grams / square meter, the thickness is 0.15mm, on the basis of ensuring the strength, it makes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com