3D printing device and method based on electromagnetic emission technique

A 3D printing and printing position technology, applied in the direction of additive processing, etc., can solve the problems of slow speed, low precision, easy blockage of nozzles, etc., to achieve the effect of expanding the range, improving printing accuracy, and ensuring printing effect and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

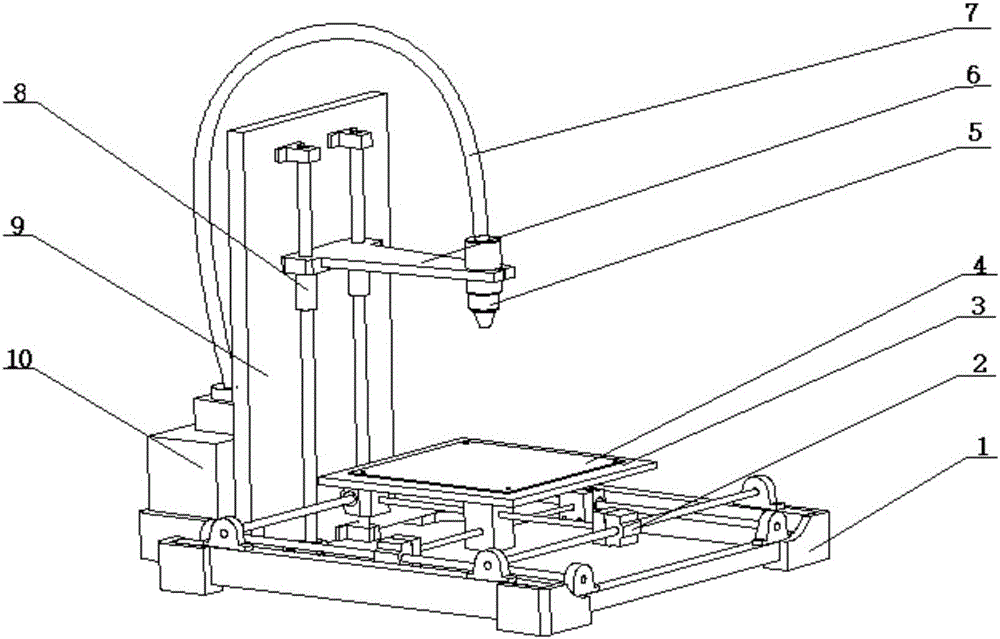

[0029] The XY direction table 2 and the bracket 9 are installed above the base 1, the Z direction table 8 is slidingly connected with the bracket 9, the connecting frame 6 is connected with the Z direction table 8, the nozzle 5 is connected with the connecting frame 6, and the high precision injection pump 10 is fixed On the base 1, both ends of the feed pipe 7 are fixedly connected to the spray head 5 and the high-precision injection pump 10 respectively, the wafer carrier 3 is installed above the XY direction workbench 2 and below the nozzle 5, and the substrate 4 is connected to the wafer carrier 3 superior;

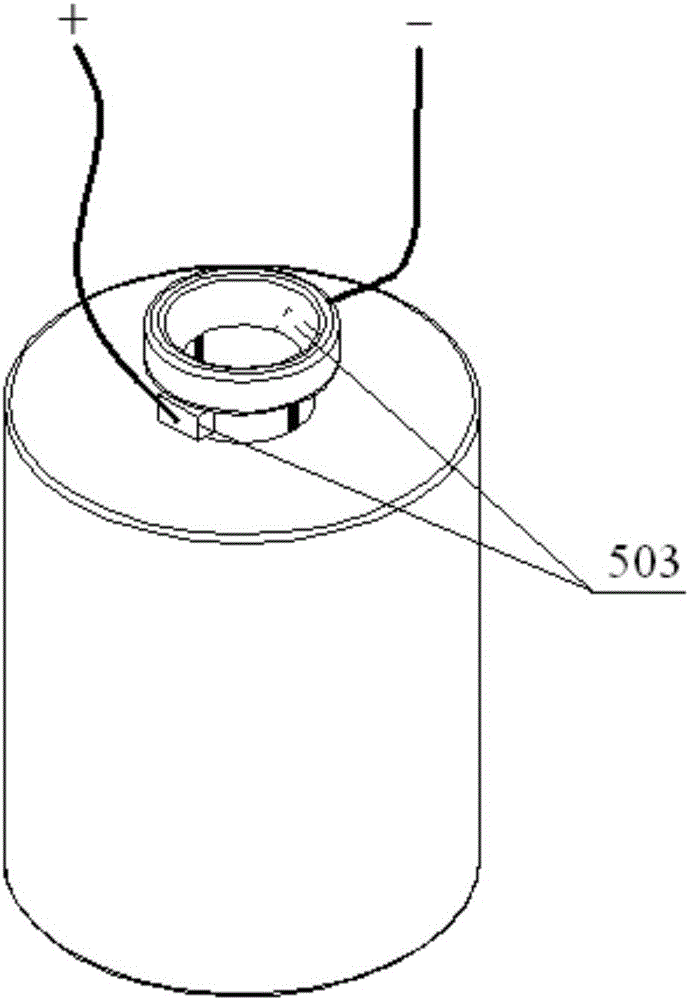

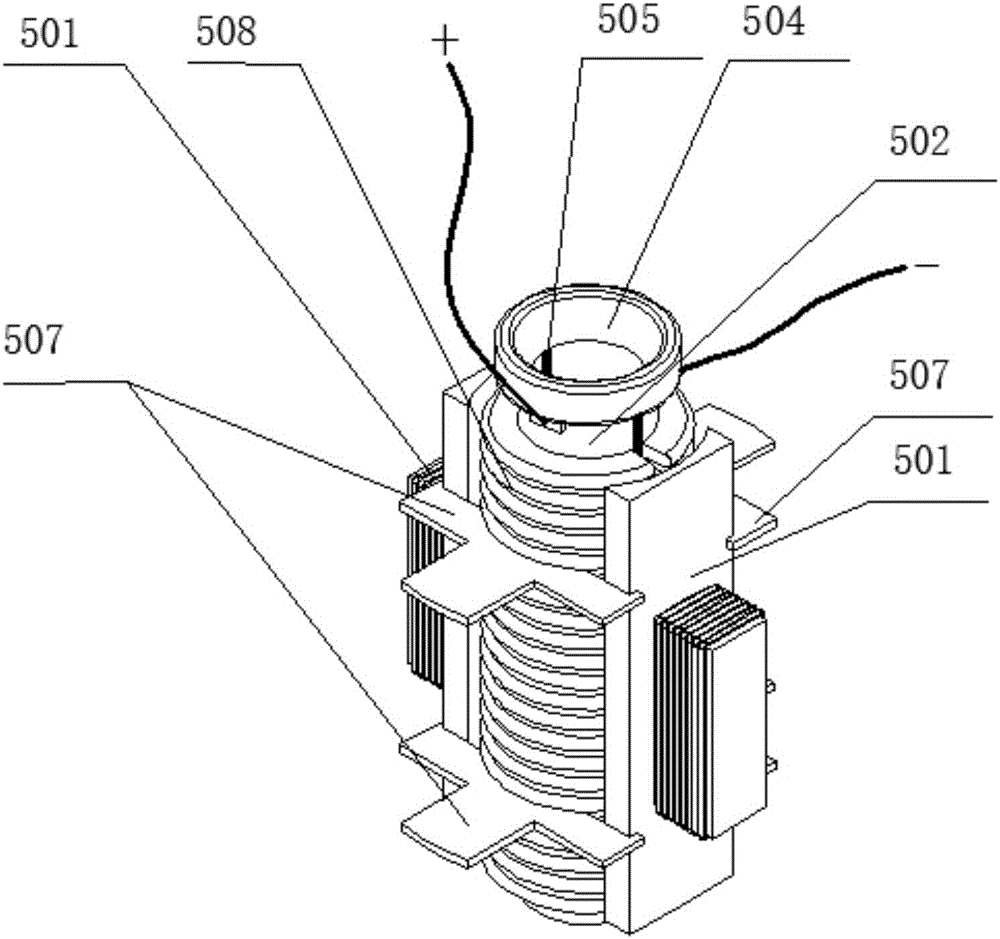

[0030] The structure of the shower head 5 is: the insulating material 505 divides the electromagnetic conduit 502 into two parts, respectively connects the positive and negative poles 503 connected to the power supply at the two parts of the electromagnetic conduit 502, the heat sink 508 is wrapped on the electromagnetic conduit 502, and the electromagnetic conduit 502...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com