Bamboo strip feeding machine

A bamboo strip and feeder technology, which is applied to the workpiece feeding device and other directions, can solve the problems of limiting the automatic production efficiency of the fine planer, high labor intensity of employees, low labor efficiency, etc., so as to reduce the interference of human factors and achieve high space utilization. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

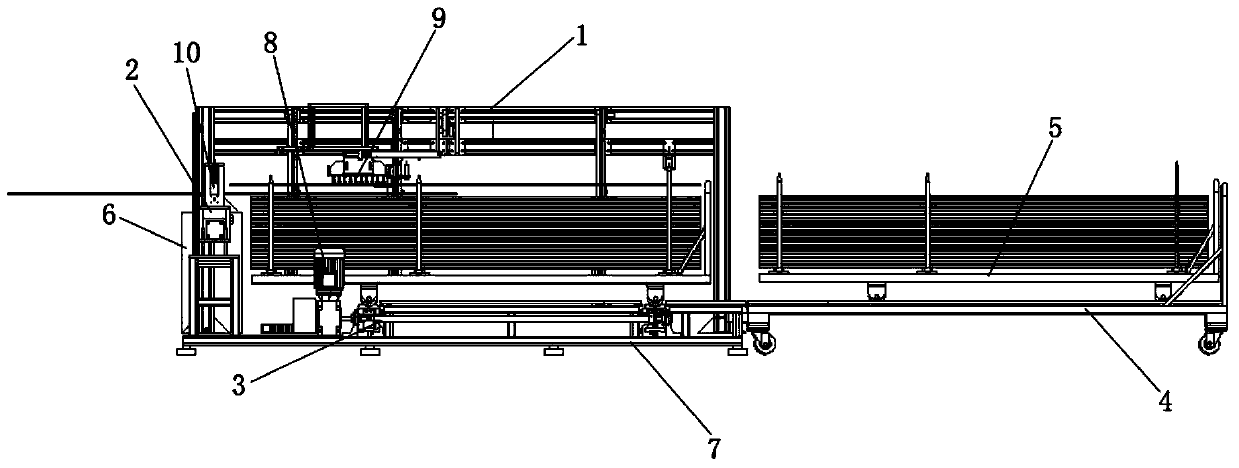

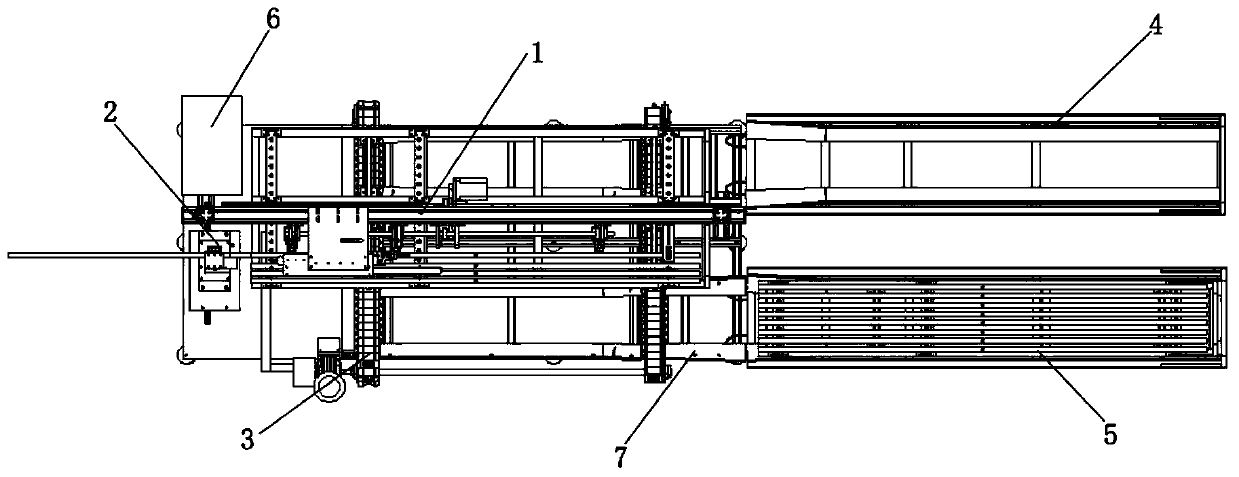

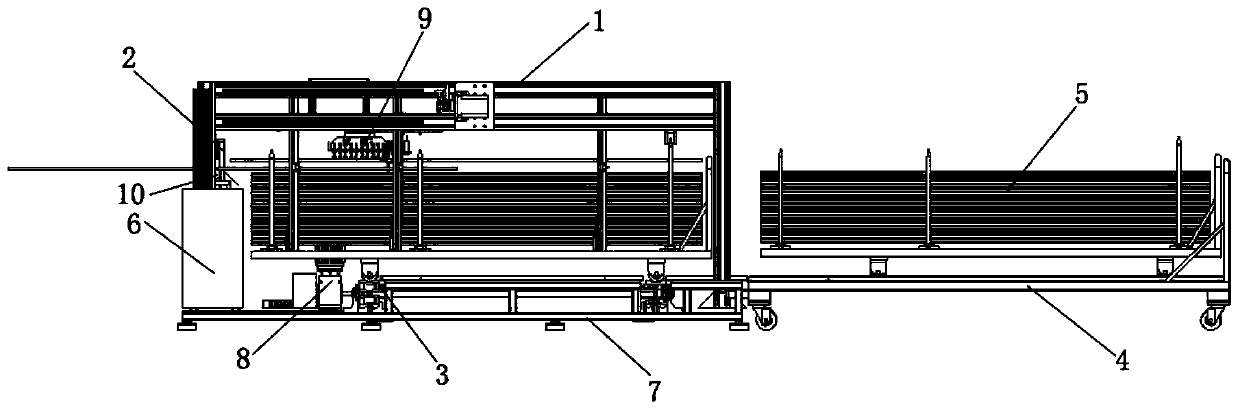

[0035] Such as Figure 1 to Figure 6 The shown bamboo strip feeder of the present invention is applied in the bamboo strip fine planing operation line to assist the fine planer to realize highly automatic fine planing processing technology. The main structure includes a feeding device 1, a coiling device 2, a transmission device 3, a pallet truck 4, a feeding truck 5 and an electric control box 6. Wherein, the transmission device 3 includes a load-bearing chassis 7, a guide rail plate group, a sprocket transmission mechanism and a drive motor 8, and a guide rail plate group for the longitudinal travel of the feeding cart 5 and a guide rail plate set for the feeding cart 5 are arranged on the load-carrying chassis 7. 5. The sprocket transmission mechanism for lateral positioning transmission. The electric control box 6 controls the drive motor 8 to dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com