Light-weight high-speed large-load lower limb exoskeleton robot

An exoskeleton robot, large-load technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of low torque and insufficient compactness, and achieve the effect of increasing compactness, increasing compactness, and improving load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

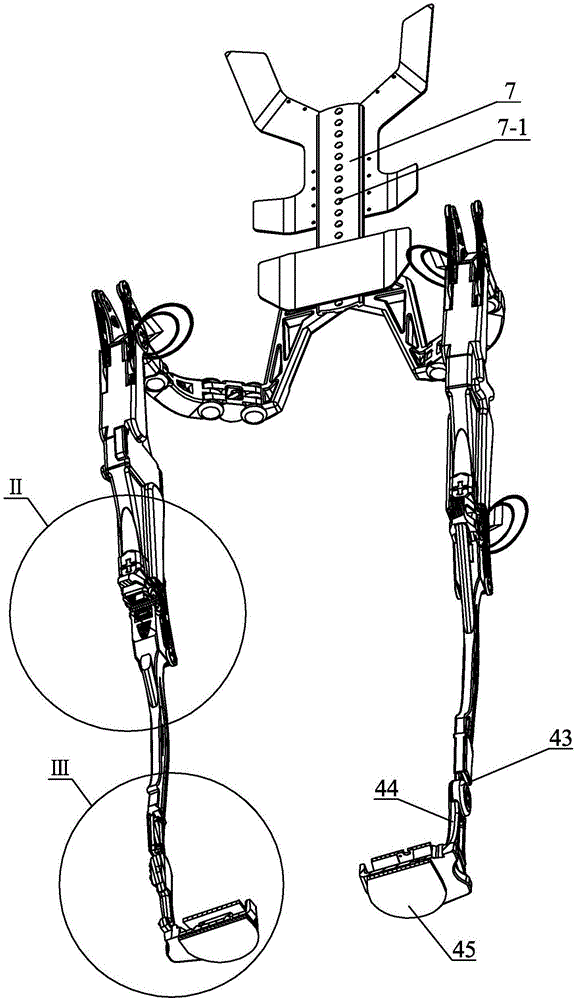

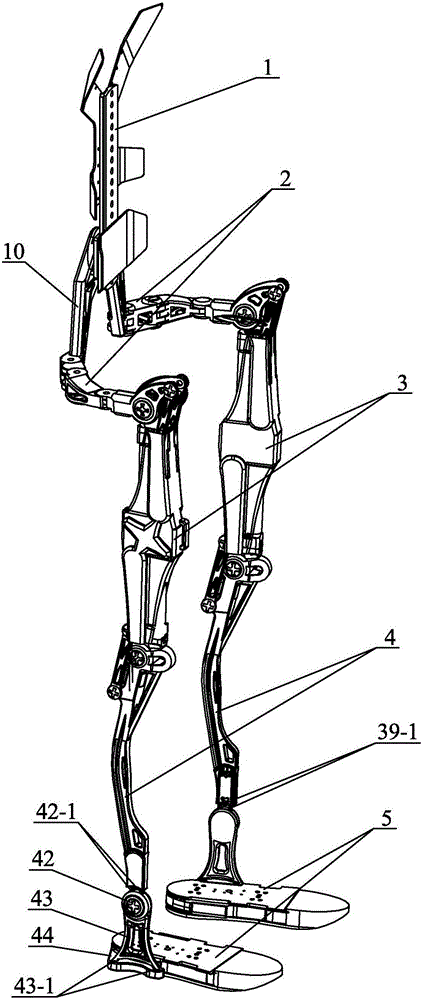

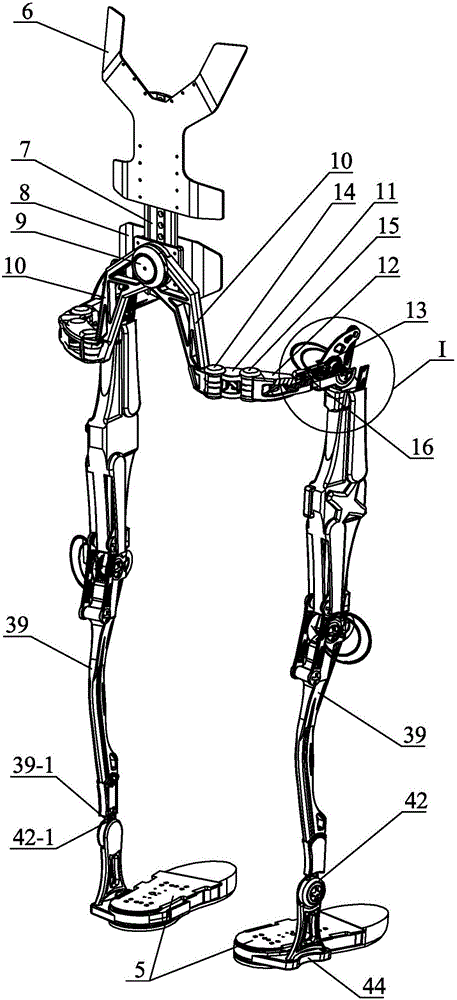

[0026] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, this embodiment includes backboard 1, connecting shaft 9, two hip joints 2, two thighs 3, two calves 4 and two foot parts 5;

[0027] Each thigh 3 comprises a hip joint hydraulic drive part and a knee joint hydraulic drive part;

[0028] The hip joint hydraulic driving components include the hip joint output connecting rod 22, the hip joint hydraulic cylinder connecting joint 23, the hip joint hydraulic piston rod 24, the hip joint hydraulic cylinder support cover 25, the hip joint hydraulic cylinder body 26 and the hip joint tension pressure sensor 33, The lower end of the hip joint hydraulic piston rod 24 is set in the hip joint hydraulic cylinder body 26, the upper end of the hip joint hydraulic piston rod 24 is connected with the hip joint tension pressure sensor 33, and the upper end of the hip joint tension pressure sensor 33 is connected with the hip joint hydraulic cylinder...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination figure 1 and image 3 Describe this embodiment, the back panel 1 of this embodiment comprises shoulder binding plate 6, adjustment plate 7 and waist binding plate 8, the upper end of adjustment plate 7 is connected with shoulder binding plate 6 by connecting element, the lower end of adjustment plate 7 It is connected with the waist binding plate 8 by connecting elements. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 To describe this embodiment, the adjusting plate 7 of this embodiment is vertically provided with a plurality of connection holes 7-1. The adjustment of the waist height is realized through the connection holes 7 - 1 at different positions on the adjustment plate 7 and the waist binding plate 8 . Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com