Magnet set vertical tungsten steel sheet distributing mechanism

A material distribution mechanism and tungsten steel sheet technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of difficulty in reaching more than 6 discharge rails, rising cost, and increasing volume, and achieve reasonable action. , quick replacement, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

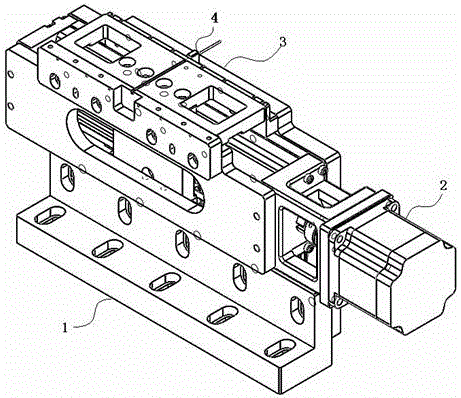

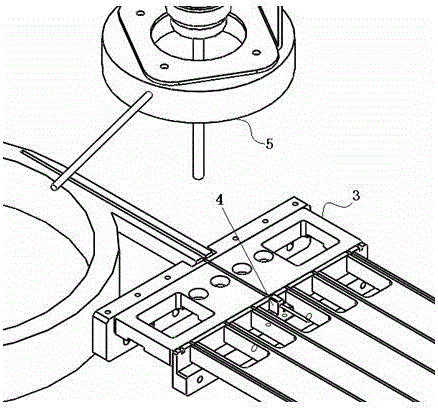

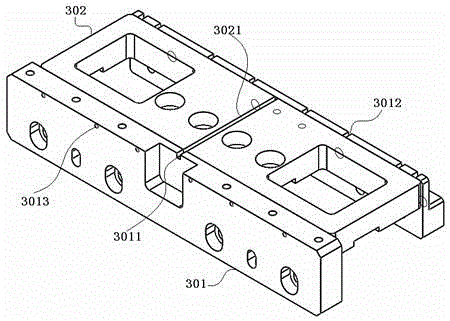

[0019] refer to figure 1 , image 3 As shown, a magnet assembly tungsten steel sheet distributing mechanism includes a base 1 and a distributing drive motor 2 arranged on the base 1, and a distributing tray mechanism 3 is also arranged on the base 1. The material tray mechanism 3 includes a fixed base 301 fixed on the base 1 and a material distribution tray 302, the material distribution tray 302 is arranged in the fixed base 301, and is driven by the power of the material distribution drive motor 2 The screw mechanism can make the distributing tray 302 move in the fixed base 301; one side of the fixed base 301 is provided with a feeding port 3011 for communicating with the tungsten steel vibrating disc track, and the other side is provided with a Several discharge ports 3012 for connecting several discharge tracks, and the side op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com