Moulding basin for moulding two ladles at same time

A double-clad and pouring, sprue basin technology is applied in casting and forming equipment, molds, cores, etc., which can solve the problems of increasing the difficulty of the pouring system and production costs, and achieves to overcome pouring defects, improve the injection speed, and achieve no coiling. gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

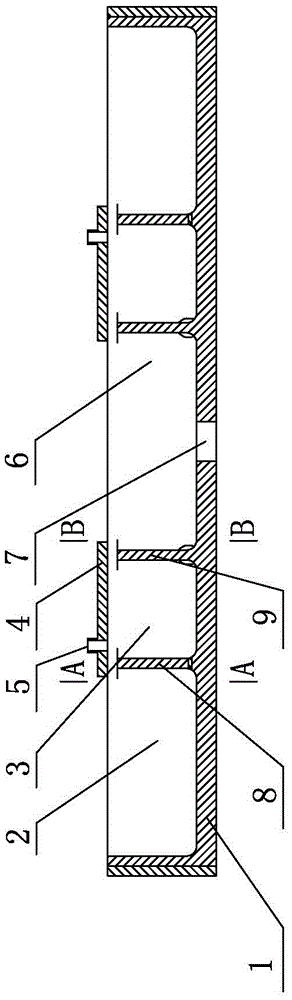

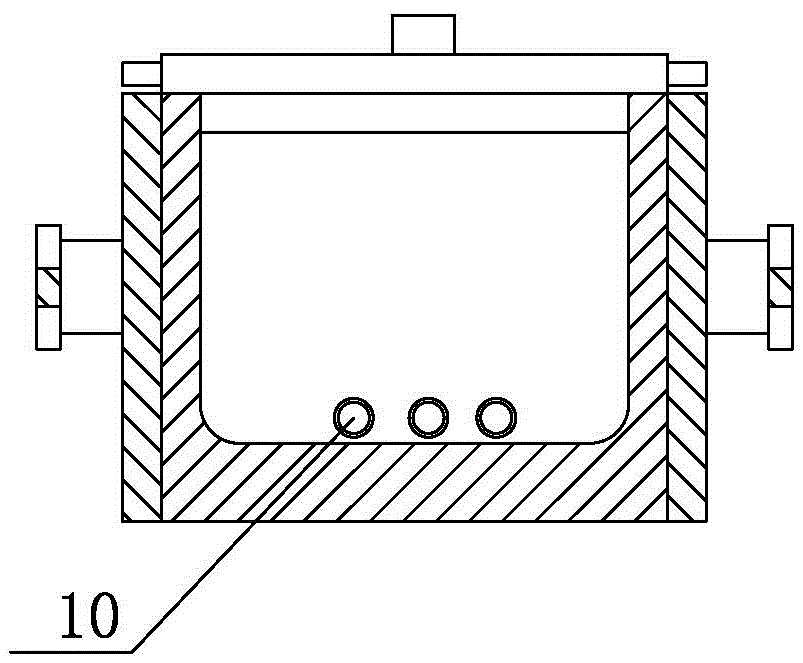

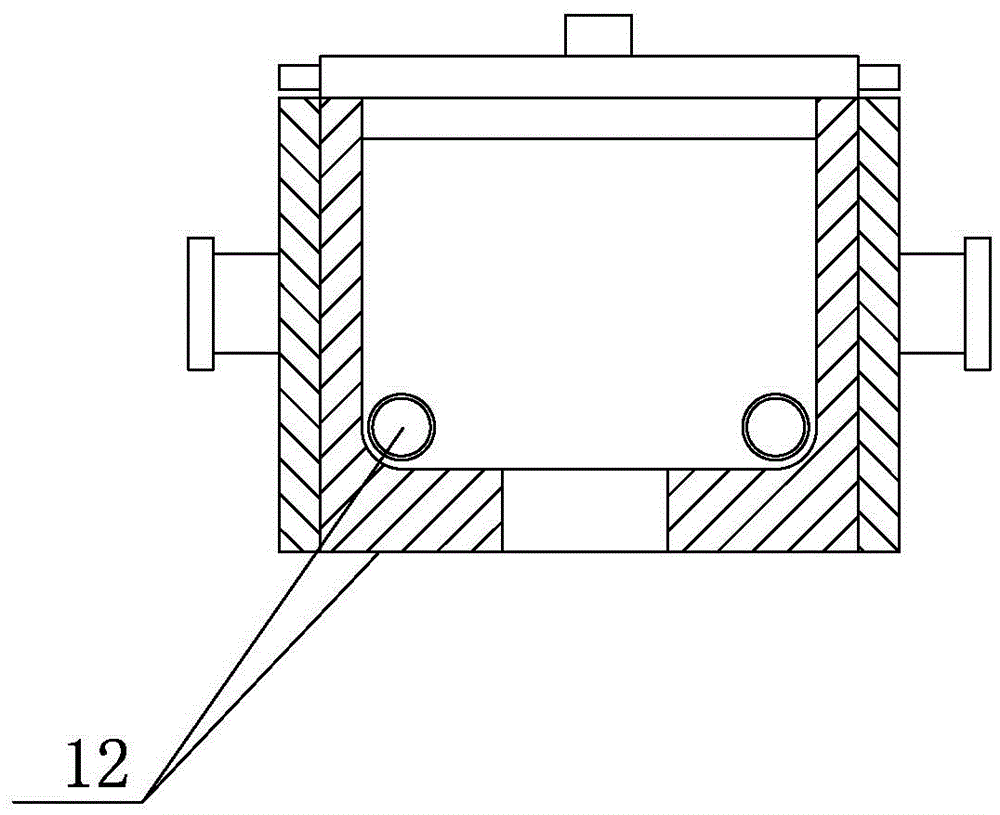

[0017] Such as figure 1 , figure 2 and image 3 As shown, it is the sprue basin for double-clad pouring of the present invention, which includes a sprue basin 1 whose length dimension is greater than the width dimension and has an open top. The middle part of the sprue basin 1 is provided with an outlet cavity 6, and the bottom wall of the outlet cavity 6 is provided with a sprue connecting port 7, and the inlet cavity 2 on both sides and the outlet cavity 6 in the middle are respectively separated by a filter cavity 3, and the The oral cavity 2 is separated from the adjacent filter cavity 3 by a partition wall 8, and the outlet cavity 6 and the filter chambers 3 on both sides are separated by a partition wall 9 respectively. The bottom of the partition wall 8 is provided with a communication inlet. A plurality of filter holes 10 of the oral cavity 2 and the filter cavity 3, and a plurality of filter holes 11 connected to the filter cavity 3 and the outlet cavity 6 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com