Light reflection single-box UV curing machine

A curing machine, single box technology, applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc., can solve the problems of poor ink adhesion, ineffective light gathering, low irradiation temperature, etc. Photo-curing efficiency, the effect of overcoming the aging of the surface layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

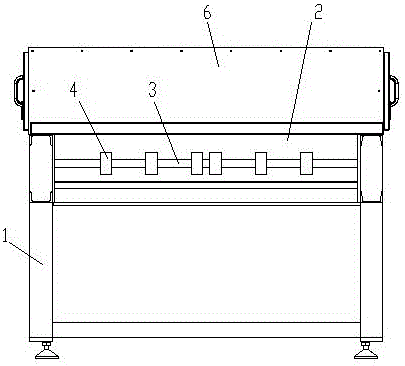

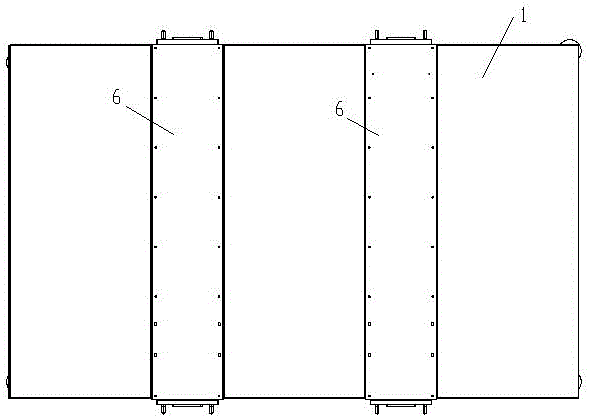

[0014] Embodiment 1: An anti-reflection single-box UV curing machine, including a frame 1, and the top of the frame 1 is set as a delivery bin 2, and the left and right sides of the delivery bin 2 are feed ports 2.1 and discharge ports 2.2, inside the transfer bin 2 A number of conveying shafts 3 are arranged side by side at intervals along the horizontal direction, wear-resistant sleeves 4 are set on the conveying shafts 3, UV lamps 5 are arranged between adjacent conveying shafts 3, and the top of the conveying bin 2 above the UV lamps 5 is directly set There is a UV box 6, and the UV lamp 5 includes a support 5.1, a lampshade 5.2 covered on the support 5.1, a vertical UV lamp 5.3 arranged at the center of the support 5.1, a hemispherical reflector 5.4 arranged below the UV lamp 5.3, The UV lamp tube 5.3 and the hemispherical reflector 5.4 are lower than the level of the conveying axis 3 . The highest point of the UV lamp tube 5.3 is located on the horizontal axis of the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com