A kind of high-temperature reactor for making lithium-ion battery negative electrode material

A high-temperature reactor, lithium-ion battery technology, applied in chemical/physical/physical-chemical stationary reactors, feeding devices, chemical/physical/physical-chemical processes, etc., to achieve a large friction coefficient and impact area, and a stable drop angle , the effect of comprehensive mixing effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

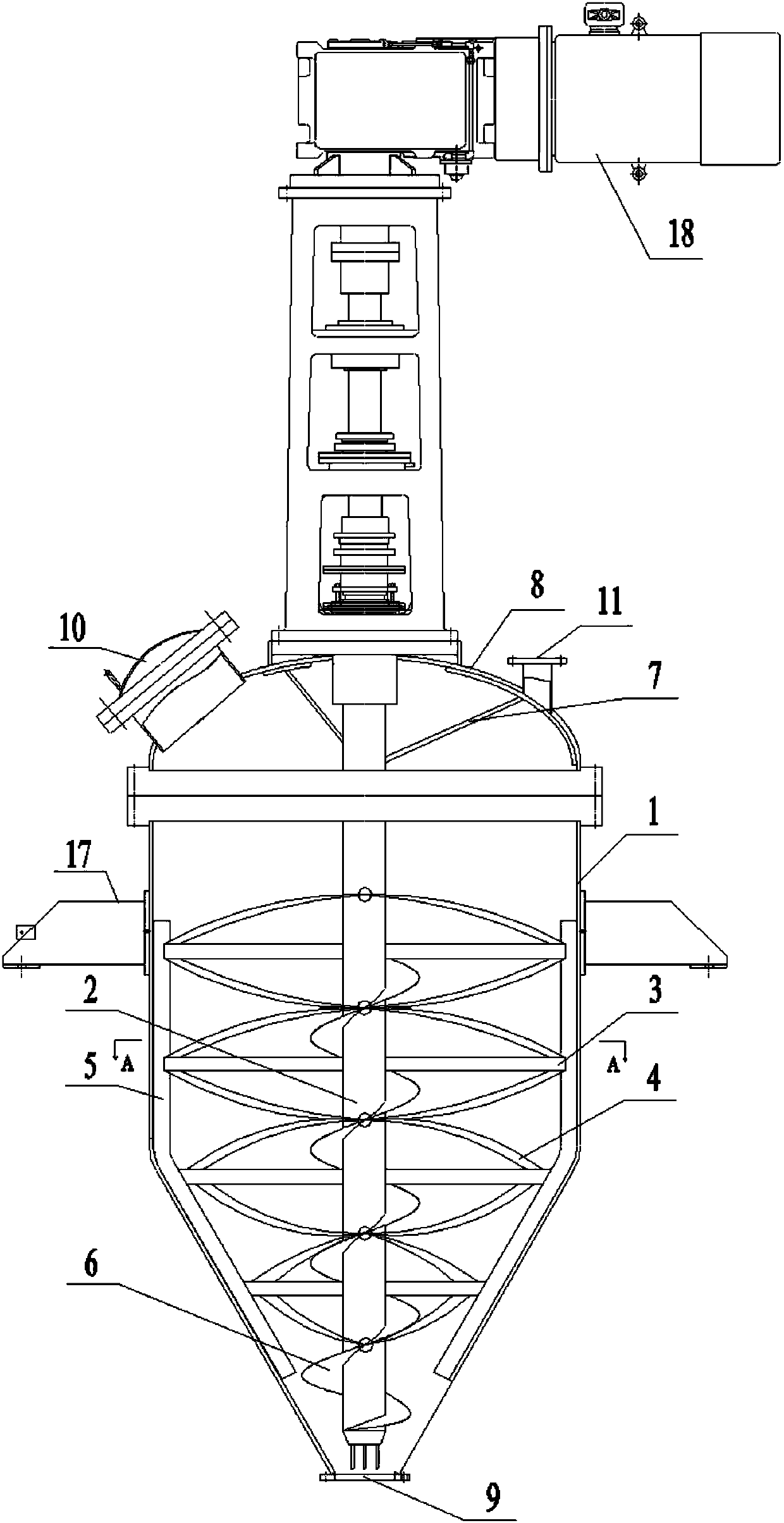

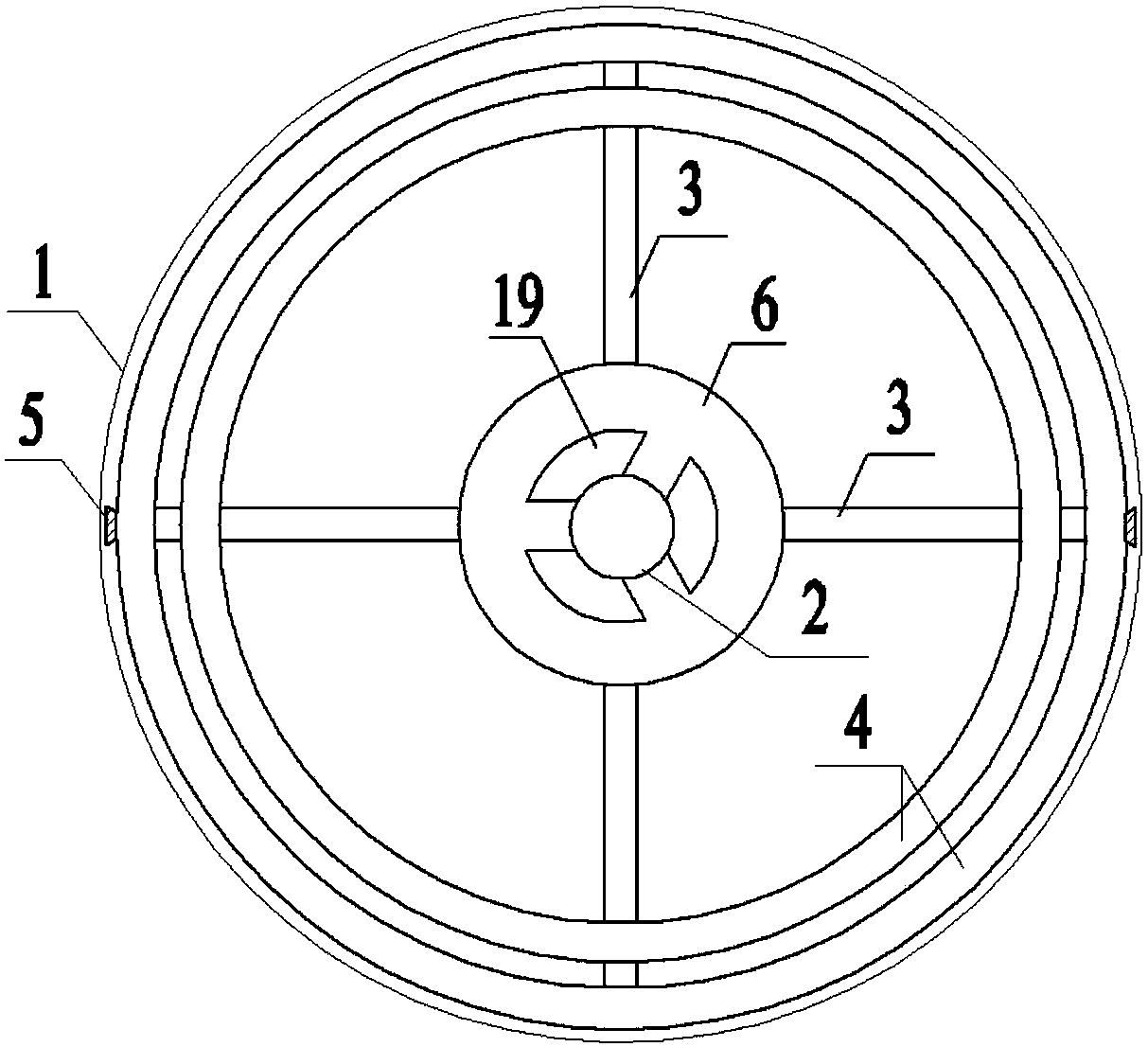

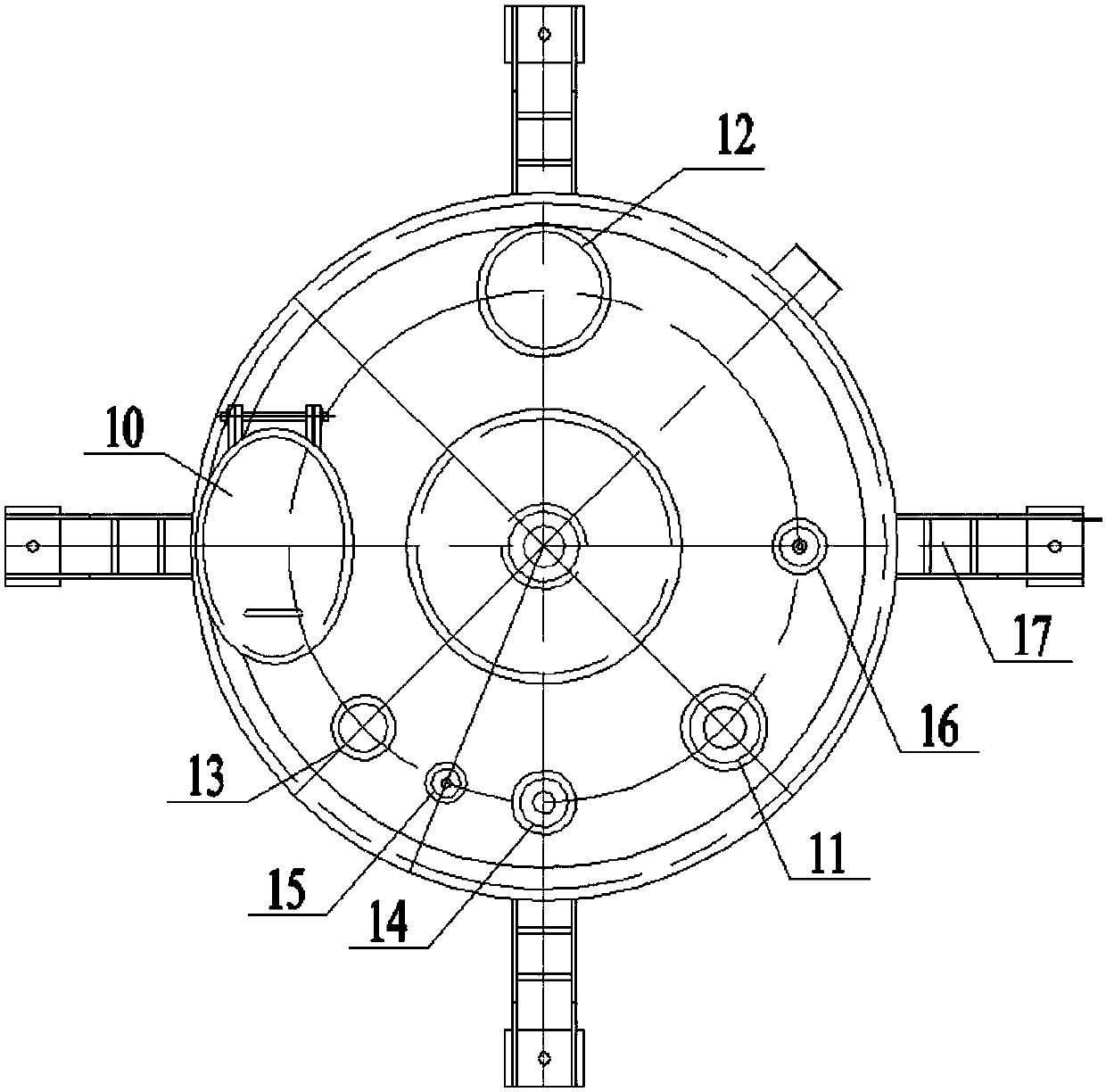

[0034]The technical solution of the present invention will be further described in conjunction with the accompanying drawings.

[0035] like Figure 1-3 As shown, a high-temperature reactor for manufacturing lithium-ion battery negative electrode materials includes a reactor body 1, and the reactor body 1 is composed of an upper double-layer insulation jacket head 8, a middle straight cylinder and a lower conical cylinder. Composed of three parts, the double-layer insulation jacket head 8 of the reactor body 1 is provided with a solid feeding port 12, a liquid inlet 13, a nitrogen inlet 14, a gas outlet 11, an inspection hole 10, a pressure gauge port 15, and a temperature measuring port. 16. Four supports 17 are welded in the upper part of the reactor body, and a discharge port 9 is provided at the bottom of the reactor body; a main shaft 2 is provided in the reactor body, and the main shaft 2 is driven by a motor 18; the high temperature The reaction kettle also includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com