Anti-cancer health-care food and preparation method thereof

A production method and food technology, applied in directions such as tea extraction, can solve the problems of inability to satisfy consumers, limited disintegration speed, poor stability, etc., and achieve the effects of improving storage stability, fast disintegration speed, and reducing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

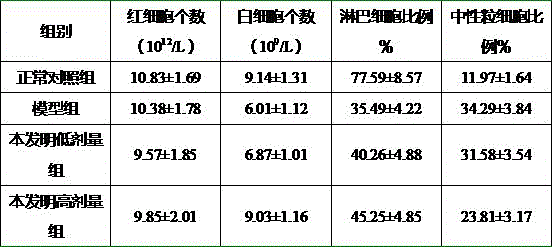

Image

Examples

Embodiment 1

[0027] Preparation:

[0028]a) After removing the core of hawthorn 100g, immerse it in water with 4 times the mass, microwave it for 15 seconds at a power of 800W, break it, add 1.2ml / kg pectinase, enzymolyze it at 40°C for 3h, make a pulp, and the slurry is in Microwave treatment at 800W power for 15 seconds, microfiltration through a ceramic membrane with a pore size of 0.2μm, adding 22g of lactose to the filtrate and stirring evenly, spray drying into powder, passing through a 100-mesh sieve, and set aside;

[0029] b) Wash 220g of figs, drain and crush, add 2 times the mass of water, then microwave for 30 seconds at a power of 300W, add 1.5ml / kg polygalacturonase, let stand for 1 hour, beat , the slurry was microwaved for 30 seconds at a power of 300W, and microfiltration was passed through a ceramic membrane with a pore size of 0.2 μm. 28 g of xylitol was added to the filtrate and stirred evenly, spray-dried into powder, passed through a 100-mesh sieve, and set aside;

...

Embodiment 2

[0035] Preparation:

[0036] a) After removing the nucleus, 220g of hawthorn is soaked in water with 3 times the mass, microwaved at 600W for 30 seconds, crushed, added with 2.0ml / kg pectinase, enzymolyzed at 60°C for 1.5h, beating, and slurry Microwave treatment for 30 seconds at a power of 600W, microfiltration through a ceramic membrane with a pore size of 0.2μm, adding 50g of lactose to the filtrate and stirring evenly, spray drying into powder, passing through a 200-mesh sieve, and set aside;

[0037] b) Wash 350g of figs, drain and break, add 5 times the mass of water, then microwave for 40 seconds at a power of 450W, add 2.5ml / kg polygalacturonase, let stand for 2 hours, beat , the slurry was microwaved for 40 seconds at a power of 450W, and microfiltration was passed through a ceramic membrane with a pore size of 0.2 μm. 32 g of xylitol was added to the filtrate and stirred evenly, spray-dried into powder, passed through a 200-mesh sieve, and set aside;

[0038] c) We...

Embodiment 3

[0043] Preparation:

[0044] a) 250g of hawthorn was denuclearized and immersed in water of 4 times the mass, microwaved at a power of 600W for 30 seconds, crushed, added 1.8ml / kg pectinase, enzymolyzed at 50°C for 2h, beating, and the slurry was Microwave treatment at 700W power for 30 seconds, microfiltration through a ceramic membrane with a pore size of 0.2μm, adding 25g of lactose to the filtrate and stirring evenly, spray drying into powder, passing through a 100-mesh sieve, and set aside;

[0045] b) Wash 360g of figs, drain and crush, add 5 times the mass of water, then microwave for 50 seconds at a power of 200W, add 2.5ml / kg polygalacturonase, let stand for 1 hour, beat , the slurry was microwaved for 50 seconds at a power of 200W, and microfiltration was passed through a ceramic membrane with a pore size of 0.2 μm. 25 g of xylitol was added to the filtrate and stirred evenly, spray-dried into powder, passed through a 100-mesh sieve, and set aside;

[0046] c) Weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com