A built-in water separation power failure thermostat, temperature control method and water separation power failure sensor

A sensor and thermostat technology is applied in the field of built-in water-disconnecting and power-off thermostats, which can solve problems such as safety accidents, rust-prone joints, and failures, and achieve the effects of ensuring personal safety, uniform thermal conductivity, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

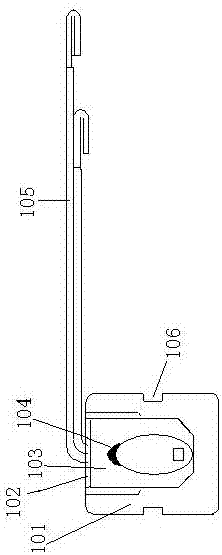

[0025] Such as figure 1 , figure 2 As shown, a water-disconnected power failure sensor includes a hollow cylindrical aluminum casing 101 with one side open. The size of the aluminum casing 101 is Φ6*7mm. There is a thermistor 102 inside the aluminum casing 101. 312-C8 resistor, two polyimide tubes 105 are connected to the thermistor 102, the sizes are 0.4*0.06*45mm and 0.4*0.06*35mm respectively, and the free ends of the two polyimide tubes 105 extend To the outside of the aluminum case 101, the gap between the thermistor 102 and the aluminum case 101 is filled with white high-temperature resin I103. The connection between the tube 105 and the thermistor 102 is coated with black resin II 104, which has a waterproof function. The outer peripheral surface of the aluminum casing 101 is provided with a circle of grooves 106 along the circum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com