Garnet-type Li-ion conductive oxide

A garnet-type, lithium-ion technology, used in electrochemical generators, electrolyte immobilization/gelling, electrical components, etc., can solve the problems of high reactivity, low lithium metal potential, and no solid electrolyte, and achieve high Effects of ionic conductivity and high sintered density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

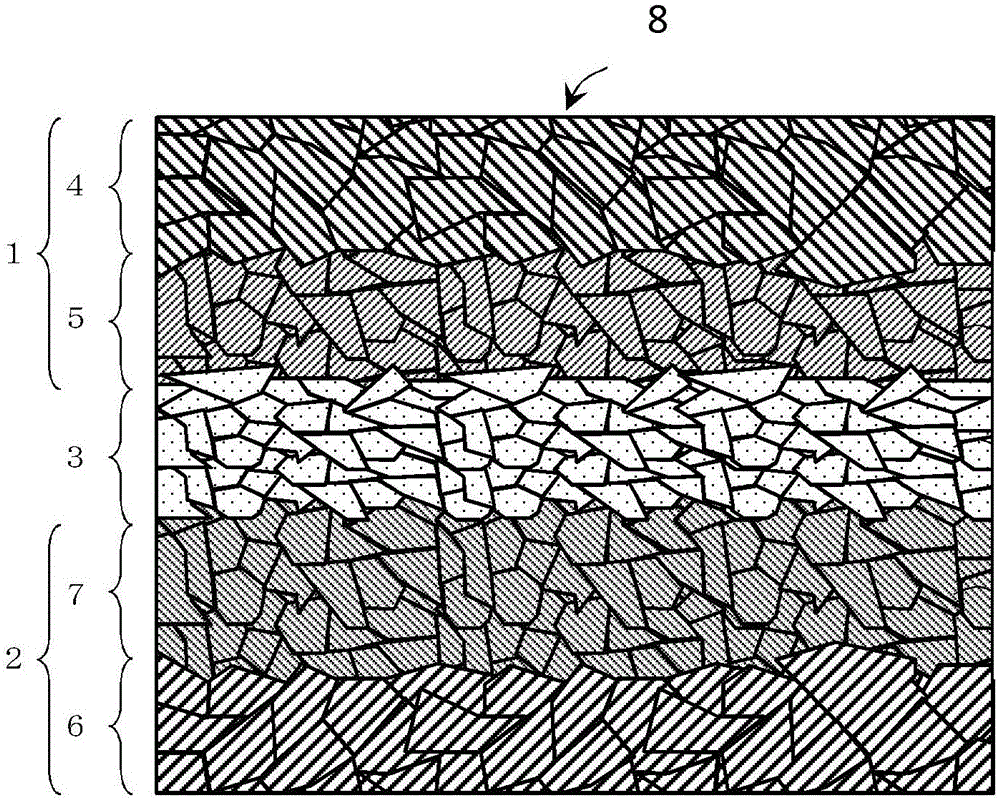

Image

Examples

Embodiment

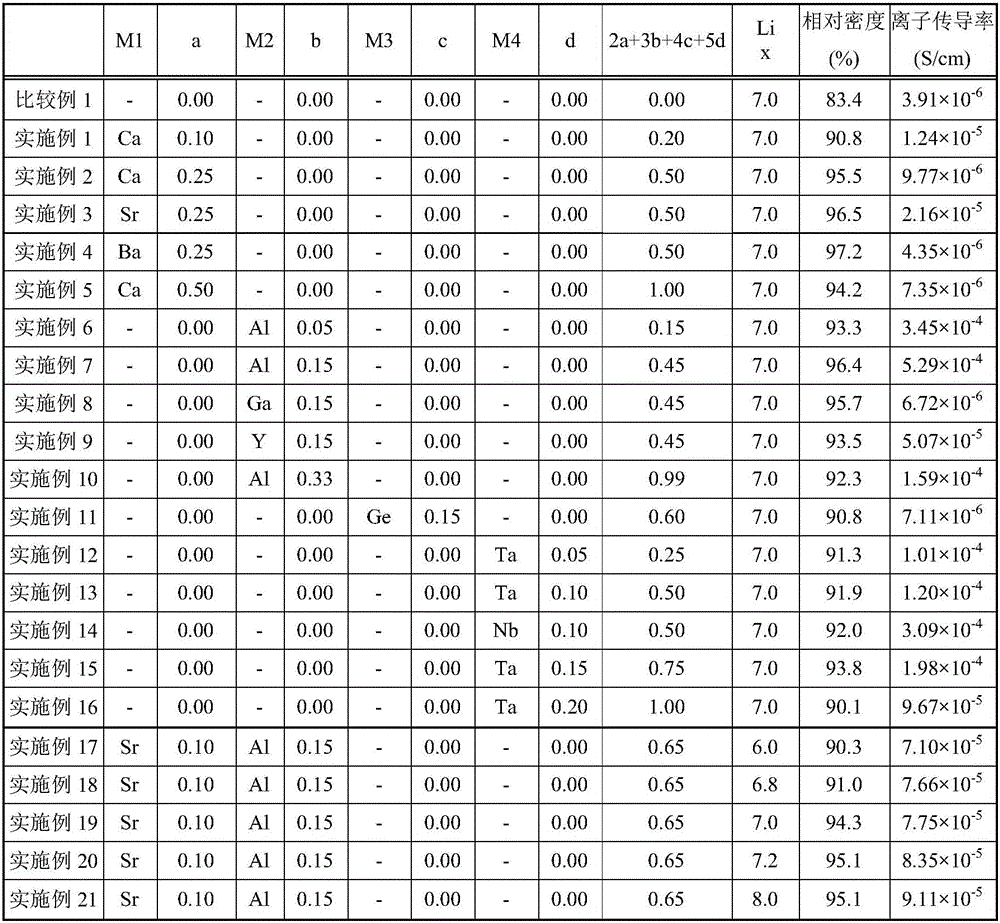

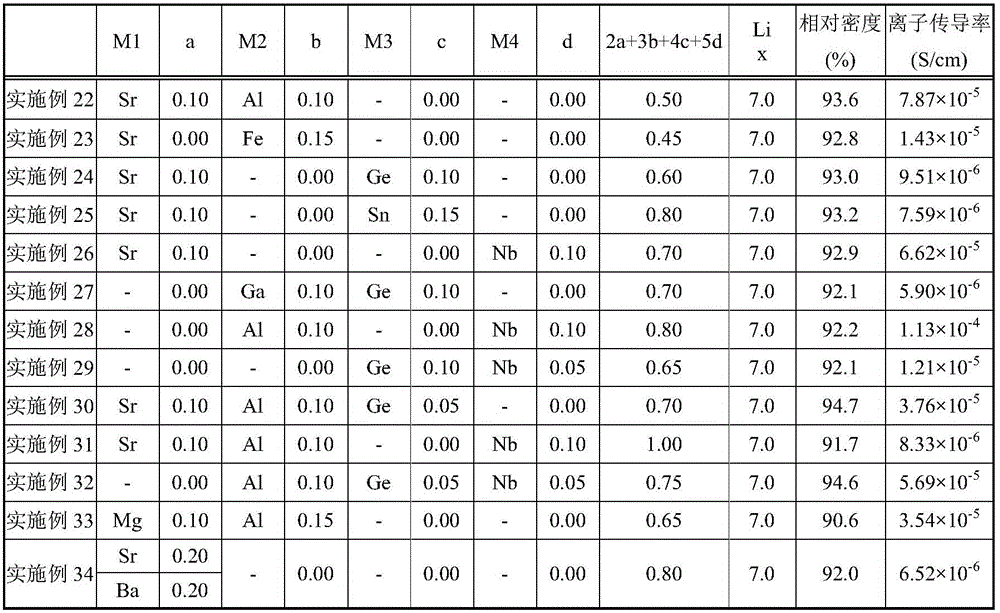

[0129] The content of the present invention will be described more specifically with reference to Examples and Comparative Examples, but the present invention is not limited to the following Examples.

[0130] As Examples 1-21, the composition formula Li of the garnet-type lithium ion conductive oxide is x-2a-3b-4c-5d M1 a M2 b M3 c M4 d La 3 Zr 2 o 12 , M1, a, M2, b, M3, c, M4, and d are as described in Table 1. The raw materials corresponding to the respective elements were weighed and mixed. As a raw material, LiCO is used 3 、La(OH) 3 , ZrO 2 , MgCO 3 , CaCO 3 , SrCO 3 、BaCO 3 、Al 2 o 3 , Ga 2 o 3 , Y 2 o 3 、GeO 2 、 Ta 2 o 5 , Nb 2 o 5 . Mixing was performed using ethanol solvent and using a ball mill (120 rpm / zirconia ball) for 16 hours.

[0131] Then, the obtained slurry was separated and dried from ethanol and zirconia balls to obtain a mixed powder.

[0132] Next, the obtained mixed powder was placed in a MgO container, and calcined at 900° C....

Embodiment 35

[0156] Examples of all-solid lithium secondary batteries are shown below, but the present invention is not limited to these examples. In addition, "part" means a mass part unless otherwise indicated.

[0157] (Production of positive electrode active material and negative electrode active material)

[0158] As the positive electrode active material and the negative electrode active material, Li 3 V 2 (PO 4 ) 3 . As the production method, with Li 2 CO 3 , V 2 o 5 , NH 4 h 2 PO 4 As the starting material, it was wet-mixed with a ball mill for 16 hours, and after dehydration and drying, the obtained powder was calcined at 850° C. in nitrogen-hydrogen mixed gas for two hours. The calcined product is wet pulverized by a ball mill, and then dehydrated and dried to obtain a powder. Using an X-ray diffraction device, it was confirmed that the structure of the produced powder was Li 3 V 2 (PO 4 ) 3 .

[0159] (Preparation of positive electrode active material slurry an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com