Wallboard structure fatigue testing machine clamp

A fatigue testing machine and fatigue testing technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of affecting the test results, troublesome implementation, and the center of the upper and lower clamps are not parallel to the center of the test piece, etc., so as to simplify the device and facilitate Simple and effective operation and overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

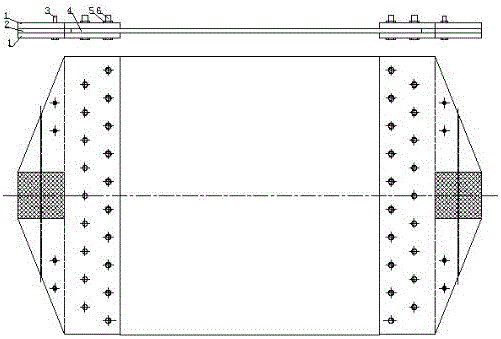

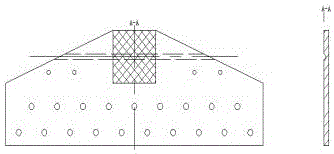

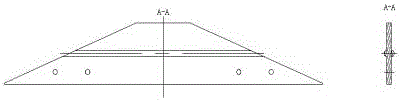

[0018] refer to figure 1 , a fixture of a panel structure fatigue testing machine consists of: a pressure plate (1), a connecting plate (2), a pin (3), a test piece (4), a high-strength nut (5), and a high-strength bolt (6). The working principle is: the pressing plate and the clamp body are tightened and connected by embossing, and the pressing plate (1) and the connecting plate (2) are connected and matched by means of circular arc grooves, in order to prevent the two corners of the lower part of the connecting plate from warping when mating , after being positioned by positioning pins, the pressure plate (1) and the test piece (4) are connected by bolts.

[0019] The basic principles and main features of the present invention and the advantages of the present invention have been shown and described above. Those skilled in the industry should understand that the present invention is not limited by the above-mentioned embodiments. What are described in the above-mentioned em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com