low nitrogen burner

A combustion head and gas technology, applied in burners, gas fuel burners, combustion types, etc., can solve the problems of inability to mix the theoretical air-fuel ratio and the mixing effect is not in the best state, so as to reduce the excess air coefficient and stabilize the combustion. , the effect of full combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: a kind of mixer, such as Figure 5 As shown, it includes a cylinder body 22 and a gas inlet 12 arranged on the peripheral wall of the cylinder body 22. The two axial ends of the cylinder body 22 are respectively set against the inlet flange 24 and the outlet flange 25. In the air flow direction, there is a gas inlet 12 along the side of the inlet flange 24 in the cylinder body 22, and a snap ring 211 is fixedly connected to the inner wall of the cylinder body 22 along the side of the outlet flange 25, and the snap ring 211 is connected to the cylinder body. 22 coaxial, the circumference of the snap ring 211 is provided with a fixed shaft 212 coaxial with the cylinder 22, and the two ends of the fixed shaft 212 are respectively fixed with a primary swirl impeller 19 and a secondary swirl impeller 20 of the same shape.

[0038] combine 4, Figure 5 , the cylinder 22 is located in the gas sub-cavity 13 and is provided with an inner cylinder 17, and the inter...

Embodiment 2

[0043] Embodiment 2: a kind of mixer, the difference with embodiment 1 is that the vane 192 of the combustion-supporting air swirl plate 14 is right-handed according to the air inlet direction of the air flow, and the primary swirl impeller 19 and the secondary swirl vane are according to The air inlet direction of the airflow is left-handed.

Embodiment 3

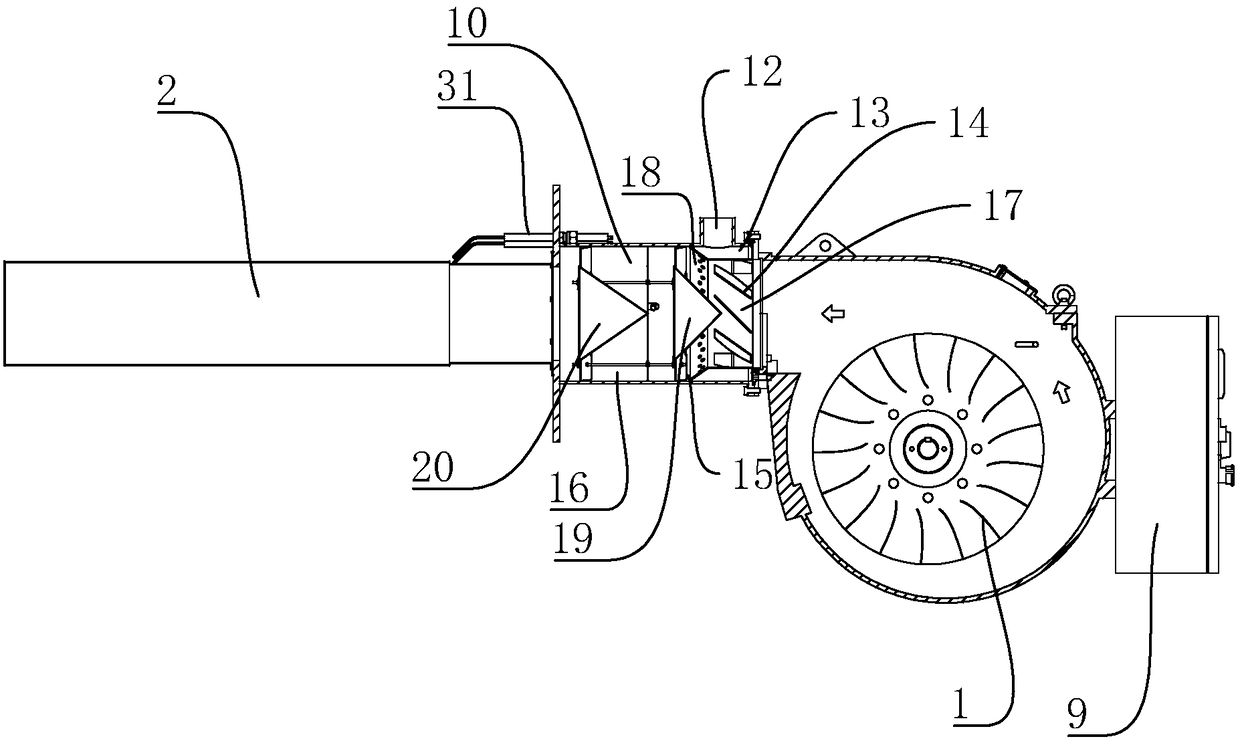

[0044] Embodiment 3: a kind of low nitrogen burner, such as figure 1 and figure 2 As shown, it includes a combustion head 2, an ignition device 3, a fan 1, a motor of the fan 1, a control cabinet 9 and the mixer 10 in Embodiment 1, and the control cabinet 9 has a PLC controller.

[0045] refer to image 3 , the barrel 22 of the mixer 10 is connected to the fan 1, the fan 1 includes the fan 1 casing and the fan 1 impeller, the outer ring of the fan 1 impeller is tangent to the axis of the barrel 22, and when the fan 1 impeller rotates, the wind flow is generated along the direction of the casing. The arc-shaped inner wall enters the inside of the barrel 22, and the outlet flange of the barrel 22 is connected to the combustion head 2. The combustion head 2 is a metal fiber combustion head. Specifically, the outer surface of the combustion head is provided with a metal fiber felt, and the metal fiber combustion head The technical application power ranges from 5kW to 40,000kW, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com