Novel variable-rigidity semi-active pipeline vibration absorber

A vibration absorber and variable stiffness technology, applied in the direction of shock absorbers, shock absorbers, pipe components, etc., can solve the problems of reduced efficiency of vibration absorbers, inability to respond well to vibration shocks, and inability to adjust, etc., to achieve high reliability, Simple structure, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

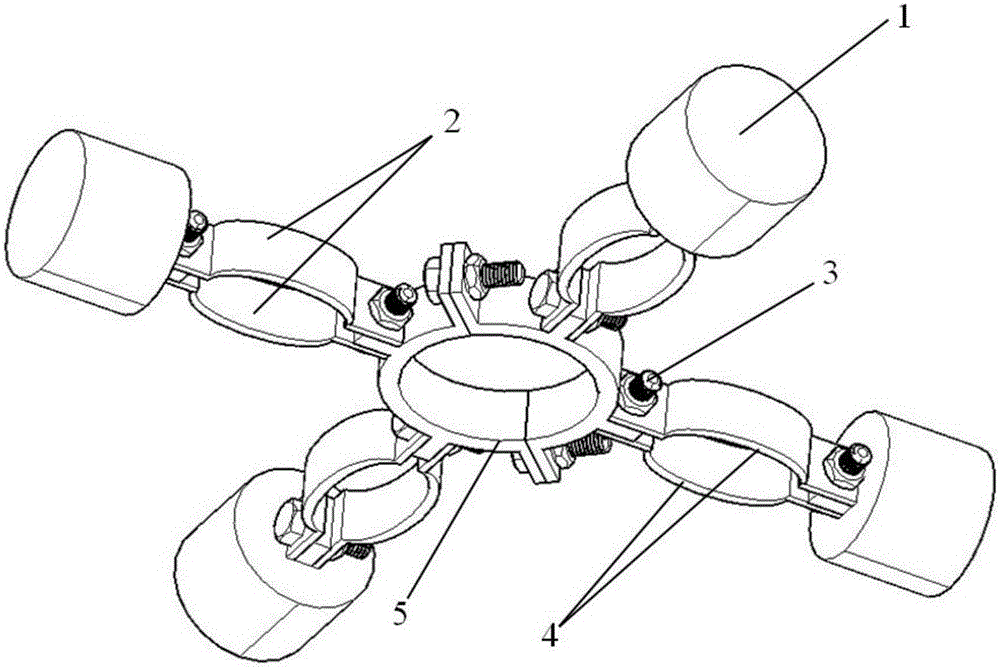

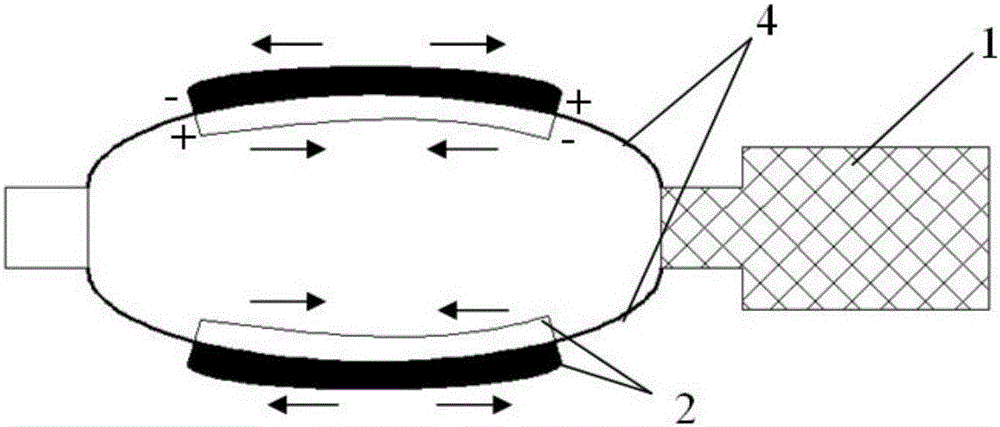

[0017] combine figure 1 with figure 2 , the present invention includes a clamping ring 5 and four sub-vibration absorbers, and the four sub-vibration absorbers are arranged in a 90° circumferential direction. Further, the sub-vibration absorbers and the clamping ring are fixed by bolts. Each sub-vibration absorber consists of two leaf springs 4, a stacked PVDF actuator 2, and an inertial mass block 1, consisting of figure 2 It can be obtained that the laminated PVDF actuator 2 is pasted on the upper and lower surfaces of the leaf spring 4 with epoxy resin. The leaf spring is selected from spring steel 65Mn with good elasticity. The thickness expansion and deformation direction of the laminated PVDF actuator is along the length direction of the leaf spring.

[0018] The laminated PVDF actuator 2 is formed by bonding N pieces (can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com