An electronically controlled common rail gasoline injection system for an internal combustion engine and its fuel injection control method

An injection system and internal combustion engine technology, applied in fuel injection control, electrical control, engine control, etc., can solve the problems of fuel pump motor power waste, complex oil return pipeline, and low pressure regulation accuracy, so as to improve engine working conditions, adjust The effect of fast speed and low energy consumption of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

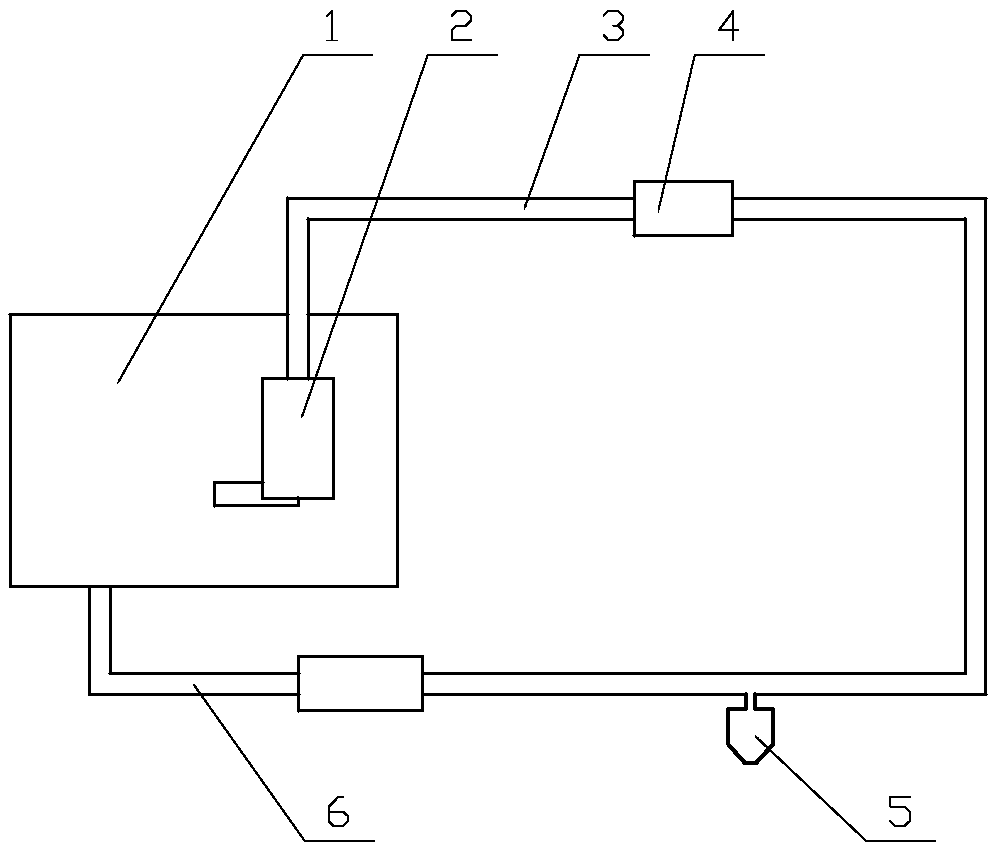

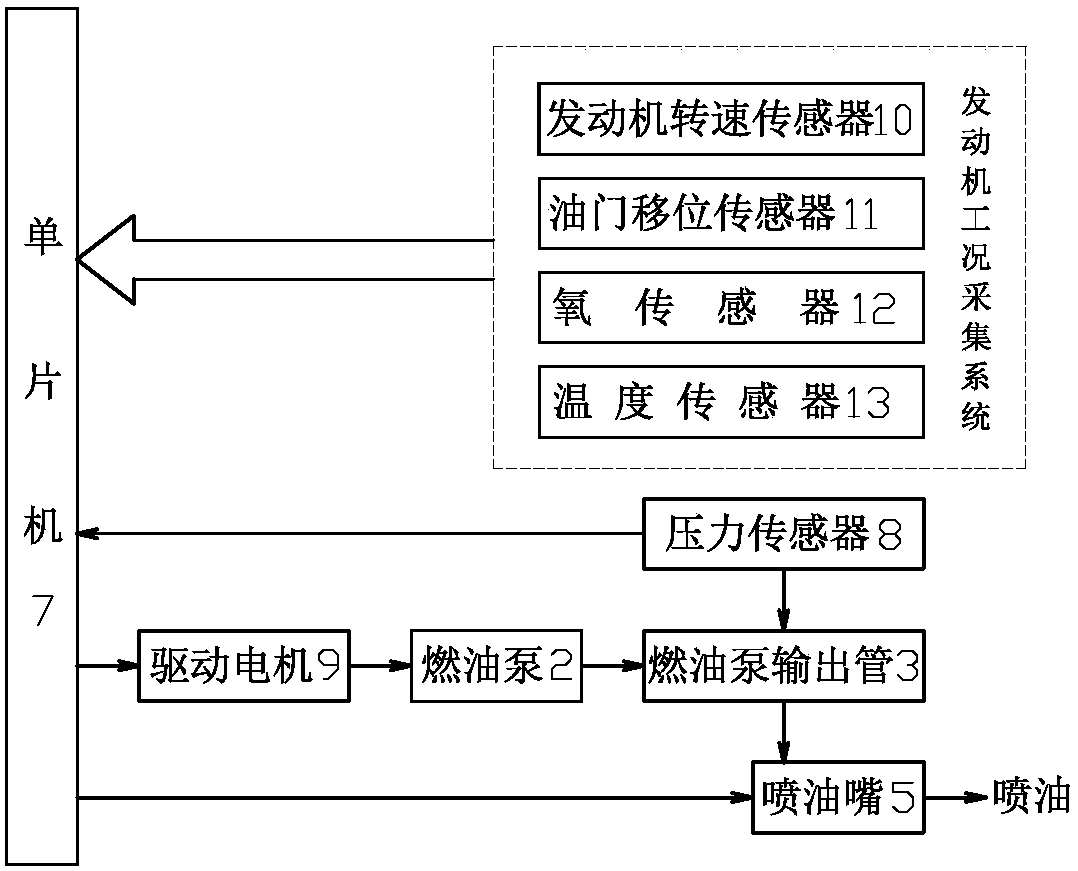

[0036] Figure 2 to Figure 7 Shown is an embodiment of an electronically controlled common rail gasoline injection system for an internal combustion engine and its fuel injection control method according to the present invention, as figure 2 As shown, it includes an engine working condition data acquisition system, a single chip microcomputer 7, a pressure sensor 8, a drive motor 9, a fuel pump 2, a fuel pump output pipe 3, and a fuel injector 5.

[0037] The engine operating condition data acquisition system includes an engine speed sensor 10 , a throttle displacement sensor 11 , an oxygen sensor 12 , and a temperature sensor 13 . The drive motor 9 is a DC brushless motor, connected to drive the fuel pump 2 . The fuel pump 2 is connected to the fuel injector 5 through the fuel pump output pipe 3 . The fuel injector 5 is a solenoid valve nozzle.

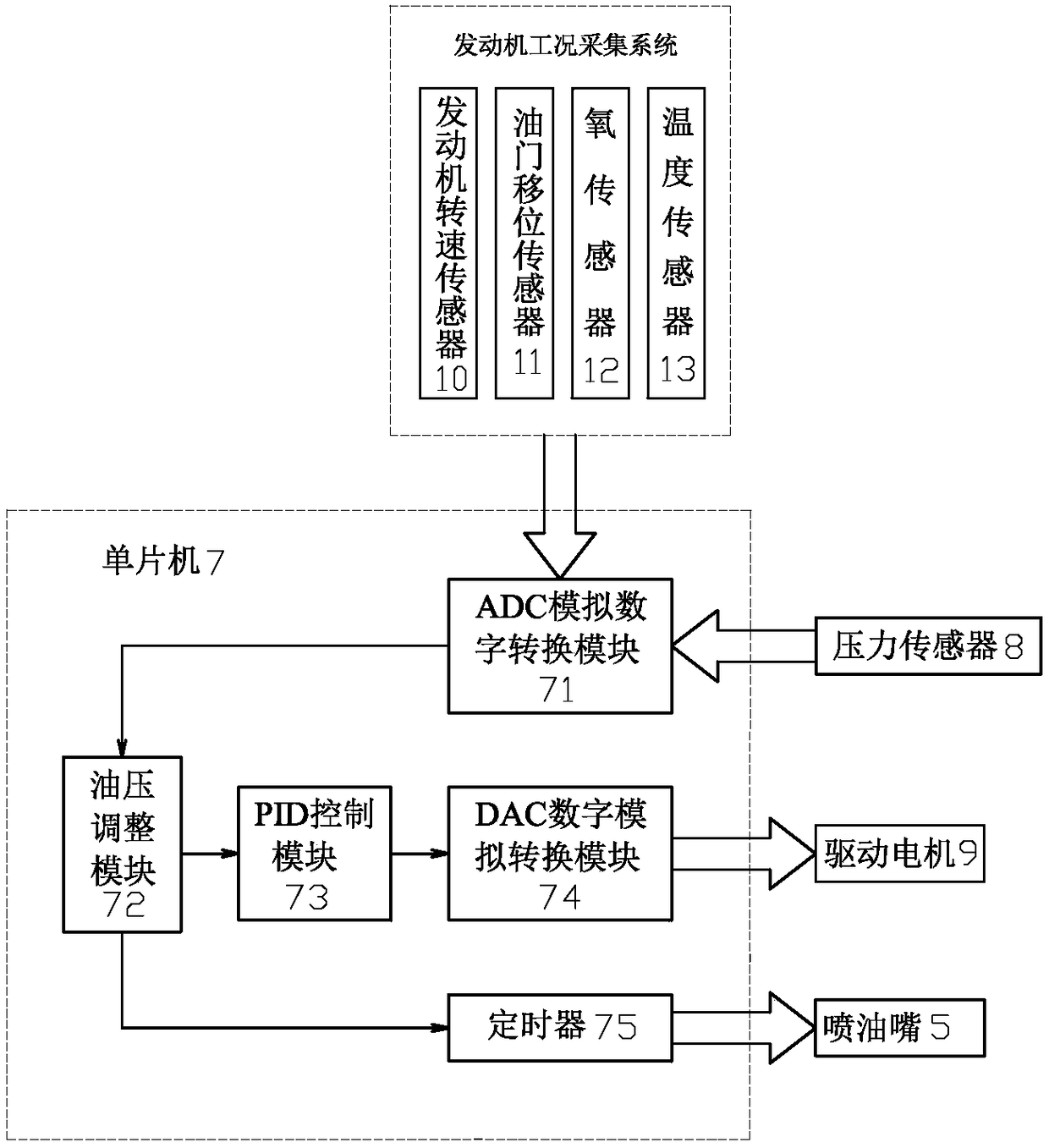

[0038] Such as image 3 As shown, the single-chip microcomputer 7 includes the following components:

[0039] The ADC analog-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com