A kind of three-dimensional wrinkle warm liner air layer fabric and its preparation method

An air layer and fabric technology, applied in the field of knitted fabrics, can solve the problems of easy stringing, complicated warp and weft knitting, and low production pass rate, and achieve the effects of improving production pass rate, strong texture layering, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

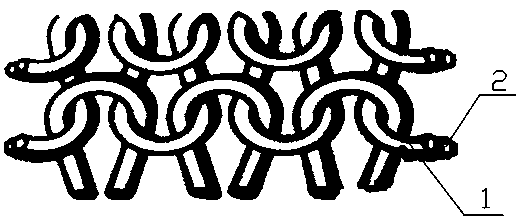

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention also provides a method for preparing the air layer fabric of the three-dimensional crepe thermal insulation liner, which includes the following steps:

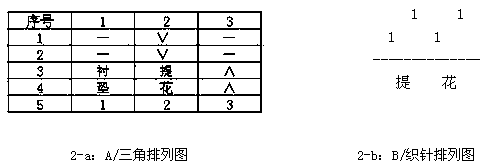

[0029] (1) Weaving, which is woven on a double-sided circular weft machine by lagging loops. The specific weaving process is as follows: figure 2 As shown, 2-a is A / triangular arrangement diagram, 2-b is B / knitting needle arrangement diagram;

[0030] (2) Dyeing and finishing treatment: the blank woven in step (1) is sequentially washed in open width—pre-setting (drying and setting at 180-190°C)—enzyme washing—draining from overflow machine—softening treatment—dehydration—spreading—tentering Drying - open width setting (dry setting).

[0031] Preferably, the presetting process includes a temperature of 180-190°C, an overfeed of 5%-15%, a vehicle speed of 20-40m / min, and a time of 30-60 seconds. The pretreatment process is: defoamer 0.06~1.2g / L, dispersant 1~4g / L, penetrant 1-4g...

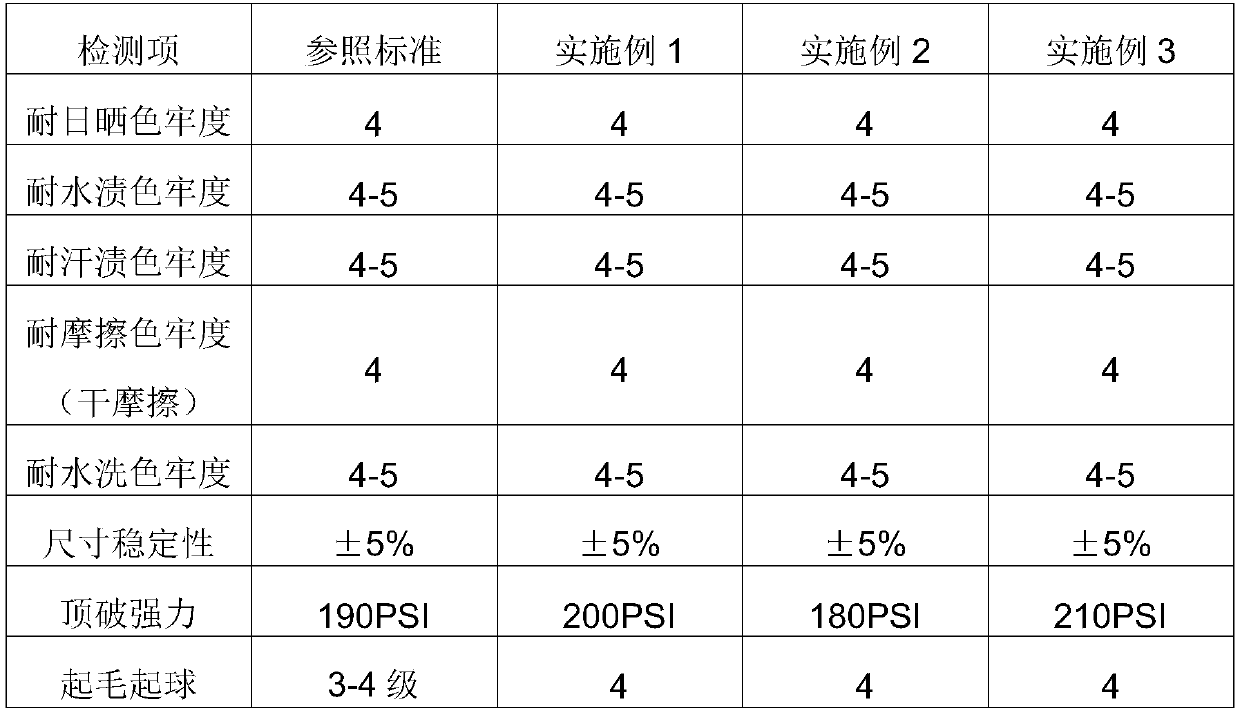

Embodiment 1

[0032] Embodiment 1 The preparation of three-dimensional wrinkle warm liner air layer fabric

[0033] (1) For weaving, the jacquard air layer structure is woven into a jacquard air layer structure by lagging loops on the double-sided circular weft machine. Cross-sectional polyester filaments, the air layer fabric adopts a hysteresis looping method to add a polyester filament under the jacquard veil;

[0034] (2) Dyeing and finishing treatment: wash the blank woven in step (1) in open width—pre-setting (180-190°C drying and setting)—enzyme washing—overflow machine draining—softening treatment—dehydration—spreading—stenter drying - open width setting (dry setting);

[0035] Among them, the pre-setting process is a temperature of 185°C, an overfeed of 10%, a vehicle speed of 30m / min, and a time of 40-50 seconds;

[0036] The pretreatment process is: defoamer 0.10g / L, dispersant 3g / L, penetrant 2g / L, hydrogen peroxide stabilizer 1g / L, soda ash 3g / L, hydrogen peroxide 6g / L, pH va...

Embodiment 2

[0039]The preparation of embodiment 2 three-dimensional wrinkle warm liner air layer fabric

[0040] (1) Weaving, the jacquard air layer structure is woven by lagging loops on the double-sided circular weft machine, wherein the jacquard veil is made of cotton yarn and spandex, the non-jacquard veil is made of short polyester fiber yarn, and the air layer fabric Polyester filaments with hollow cross-section are used, and a polyester filament is added under the jacquard veil in the air layer fabric by lagging and looping;

[0041] (2) Dyeing and finishing treatment: the blank woven in step (1) is sequentially washed in open width—pre-setting (drying and setting at 180-190°C)—enzyme washing—draining from overflow machine—softening treatment—dehydration—spreading—tentering Drying - open width setting (drying setting);

[0042] Among them, the pre-setting process is a temperature of 185°C, an overfeed of 10%, a vehicle speed of 30m / min, and a time of 45 seconds;

[0043] The pret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com