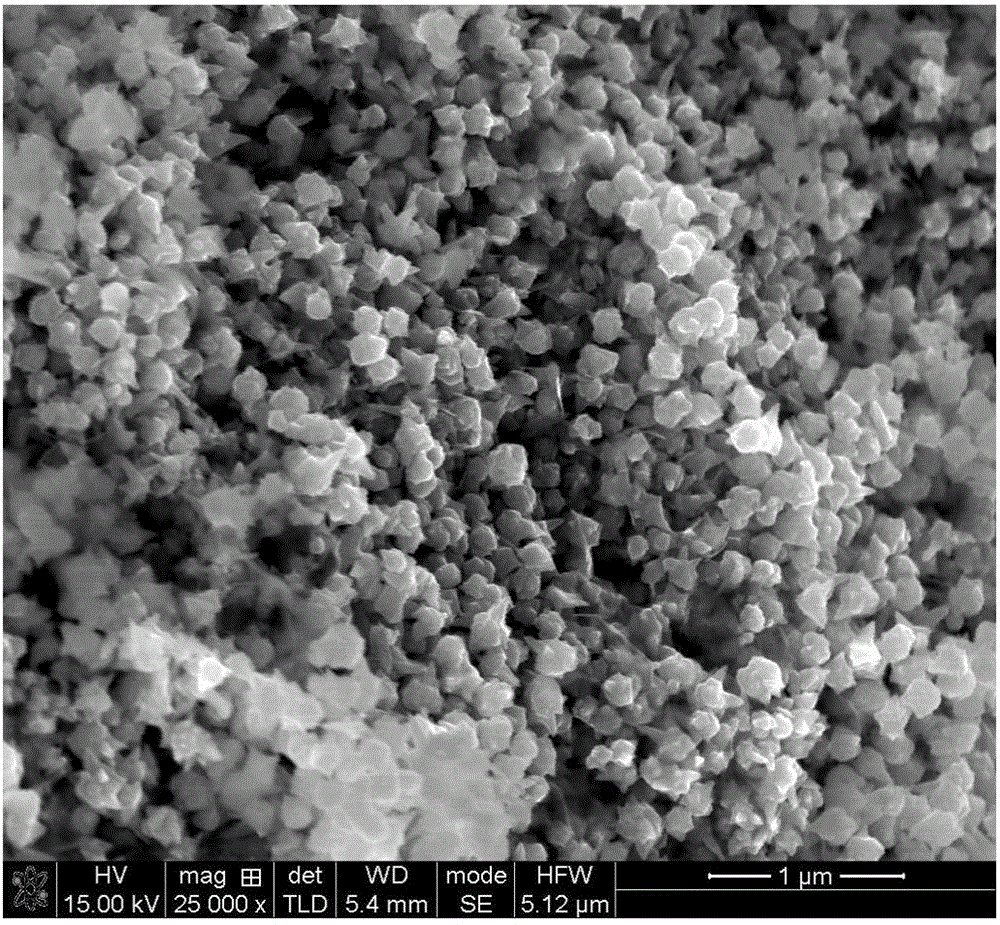

Metal aerogel with high specific surface area and preparation method thereof

A high specific surface area, airgel technology, applied in the direction of airgel preparation, chemical instruments and methods, metal material coating technology, etc., can solve the problems of high metal density, difficult to obtain airgel, etc., and achieve high specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of high specific surface area metal airgel, comprising the following steps:

[0033] Step 1. Weigh 1g of microcrystalline cellulose and 49g of 1-allyl-3-methylimidazolium chloride salt (purity 98%) in a beaker, place in an oil bath at 80°C for 4 hours to completely dissolve the cellulose, Then place the beaker in a vacuum oven at 80°C for 2 days; take the beaker out of the oven and add EtOH / H 2 O solution regenerates the gel and prepares cellulose airgel; the EtOH / H 2 The volume fraction of EtOH in the O solution is 80%;

[0034] Step 2. Weigh 0.05g PdCl 2 In a beaker, add 45mL of ethanol (EtOH) and 5mL of 1mol L -1HCl is ultrasonically dissolved in an ultrasonic cleaner to obtain PdCl 2 Sensitization solution; place cellulose airgel in PdCl 2 Perform sensitization treatment in the sensitization solution, take it out after 1 day, and rinse with deionized water to remove the PdCl enriched on the surface of the cellulose airgel 2 ;

[0035] Ste...

Embodiment 2

[0039] A preparation method of high specific surface area metal airgel, comprising the following steps:

[0040] Step 1, adopt the method in embodiment 1 to prepare cellulose airgel;

[0041] Step 2: Prepare 100mL 0.1mol·L respectively -1 PdCl 2 solution and SnCl 2 Solution, the prepared cellulose aerogels were respectively in SnCl 2 and PdCl 2 Soak in the solution for 1 day, then rinse with deionized water;

[0042] Step 3, place the processed cellulose airgel in step 2 in Cu chemical plating solution, carry out chemical plating at normal temperature, change 1 Cu chemical plating solution every two days, repeat the cycle like this until the solution becomes free Color, obtain Cu / cellulose composite airgel; Cu electroless plating solution formula is: sodium citrate 15g / L, boric acid 30g / L, anhydrous copper sulfate 10g / L and sodium hypophosphite 30g / L;

[0043] Step 4: Weigh 4.6g of LiOH and 15g of urea in a beaker, then add 80.4mL of deionized water and stir to dissolve ...

Embodiment 3

[0046] A preparation method of high specific surface area metal airgel, comprising the following steps:

[0047] Step 1. Add 1g of microcrystalline cellulose into 50mL LiOH / urea solution, dissolve the microcrystalline cellulose at -22°C, and add EtOH / H 2 O solution regenerates the gel and prepares cellulose airgel; the EtOH / H 2 The volume fraction of EtOH in the O solution is 80%; the preparation method of the LiOH / urea solution is: take LiOH 4.6g, urea 15g in a beaker, then add 80.4mL deionized water and stir to make it dissolve completely to obtain LiOH / urea solution;

[0048] Step 2: Prepare 100mL 0.1mol·L respectively -1 PdCl 2 solution and SnCl 2 Solution, the prepared cellulose aerogels were respectively in SnCl 2 and PdCl 2 Soak in the solution for 1 day, then rinse with deionized water;

[0049] Step 3, place the cellulose airgel treated in step 2 in Ag chemical plating solution, carry out chemical plating at normal temperature, replace 1 Ag chemical plating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com