Straw gasifier gas production and filtering apparatus

A filter device and gasifier technology, which is applied in the field of straw gasifiers, can solve problems such as unstable use status and structural defects, and achieve the effect of improving combustion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

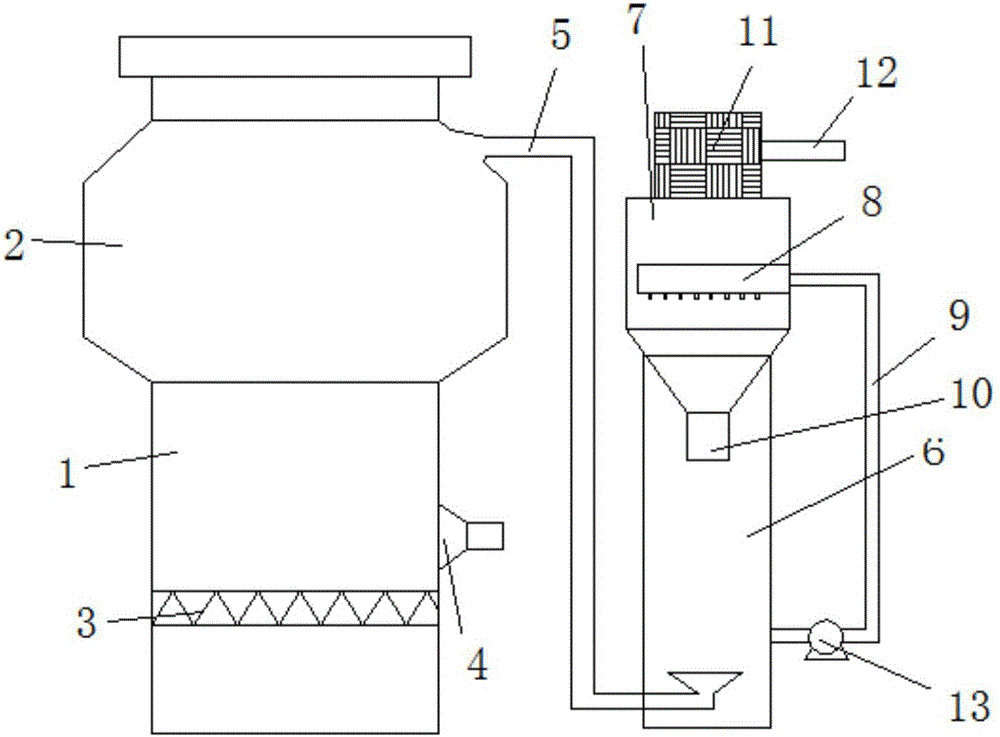

[0010] Referring to the accompanying drawings, a straw gasification furnace gas filter device includes a furnace body 1, the upper end of the furnace body 1 is provided with a flared section 2, the flared section 2 is a straw storage tank, and the furnace body The inner wall of the lower half of 1 is provided with a barbed wire layer 3, the side wall of the furnace body above the barbed wire layer 3 is provided with an air inlet pipe 4, and the outer wall of the storage tank is connected with an exhaust pipe 5, and the One end of the exhaust pipe 5 is connected to a filter cartridge 6, and a spray tank 7 is connected above the filter cartridge 6, and a spray head 8 is installed in the spray tank 7, and the spray head 8 is connected to the filter through a pipe 9. The pool at the bottom of the cylinder 6, the lower part of the spray tank 7 is provided with a tapered feeding port 10, the upper end of the spray tank 7 is connected to the dehumidification layer 11, and the side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com