PA6 buckle material for fixing sound-absorbing module and preparation method of material

A buckle and sound mold technology, applied in the field of PA6 buckle material and its preparation, can solve the problems of low degree of freedom, single shape, and troublesome installation of aluminum alloy materials, so as to ensure long-term use performance, easy installation, and uniform fiber. The effect of the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1, a PA6 buckle material used to fix the sound-absorbing module is composed of 85kg of PA6 BL2280, 15kg of glass fiber ECS301CL, 0.8kg of antioxidant 1010, 0.1kg of antioxidant 168, and 1kg of UV 770, 0.1kg of UV944, 3kg of carbon black, 0.1kg of lubricant AC-540, the preparation method is: mix other components except glass fiber together in a low-speed mixing equipment for 3-30 minutes, The mixed material is put into the main silo of the twin-screw extruder, and the glass fiber is put into the side silo, melted and extruded at a barrel temperature of 180-250°C, cooled by conveyor belt or water bath, and then passed through a pelletizer. Granulate to obtain PA6 buckle material for fixing the sound-absorbing module.

Embodiment 2

[0017] Example 2, a PA6 buckle material used to fix the sound-absorbing module is made of 50kg of PA6 BL2280, 50kg of glass fiber ECS301CL, 0.1kg of antioxidant 1098, 0.8kg of antioxidant 168, and 0.1kg of UV2020, 1kg of UV234, 1kg of carbon black, and 0.1kg of lubricant calcium stearate are made, and its preparation method is the same as in Example 1.

Embodiment 3

[0018] Example 3, a PA6 buckle material used to fix the sound-absorbing module is made of 65kg of PA6 BL2280, 35kg of glass fiber ECS301CL, 0.4kg of antioxidant 1010, 0.5kg of antioxidant 168, and 0.5kg of The UV622 of UV 4050, 0.6kg, the carbon black of 2kg, the lubricant WE-3 of 0.55kg are made, and its preparation method embodiment 1 is the same.

[0019] The embodiment of the present invention adopts but is not limited to the following equipment: vertical or horizontal high and low mixing equipment, parallel twin-screw L / D=30-50 extrusion equipment, adopts a water bath or conveyor belt wind cooling mode, and is processed by a pelletizer. pellets to produce the final specialty material.

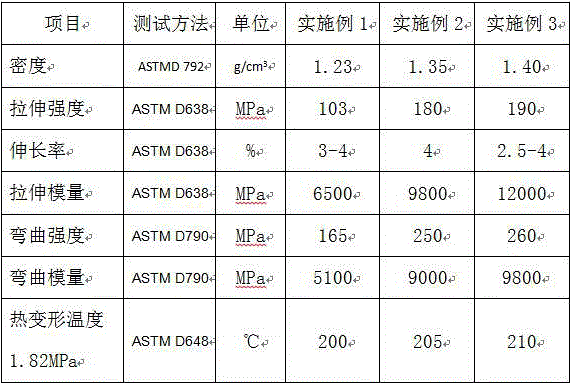

[0020] Material properties of the present invention:

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com