A kind of pvc composite material

A talcum powder and blending technology, applied in the field of wood-plastic product topcoat production, can solve the problems of reduced product surface glossiness, insufficient product surface hardness, hidden danger of product personal safety, etc. The effect of aging performance, UV resistance and anti-aging performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

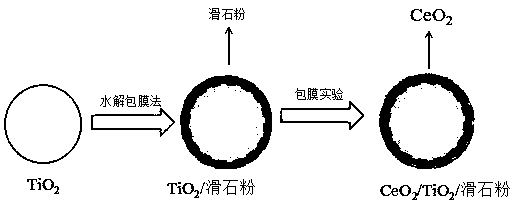

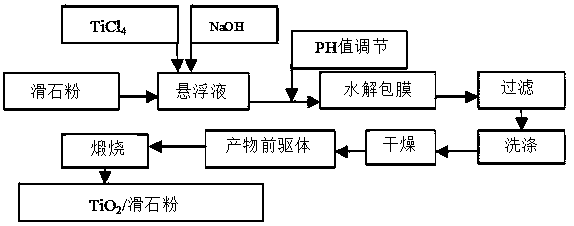

Method used

Image

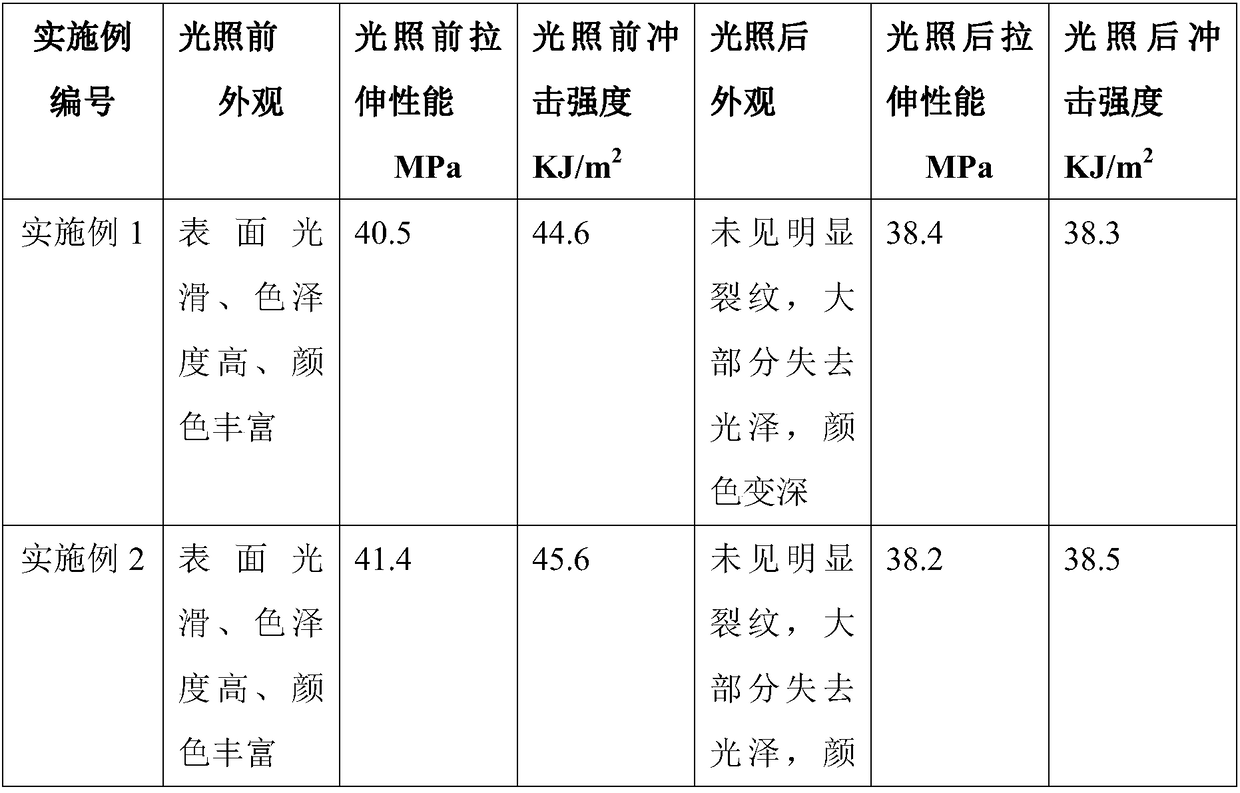

Examples

Embodiment 1

[0035] The preparation of wood-plastic products by the two-step extrusion method mainly includes two technological processes: the mixing and granulation process and the co-extrusion molding process.

[0036] Mixing and granulation process: first mix wood powder and calcium powder (if necessary, treat with surface modifier to improve its poor dispersion effect in molten thermoplastics, often exist in the form of a certain aggregation state, melt flow poor performance, difficulty in extrusion molding, etc.), then pre-dry the above-mentioned wood powder and calcium powder through a constant temperature drying oven, and mix them with PVC, flame retardant, internal lubricant and external lubricant in a high-speed mixer for 2 hours, and cool After reaching a certain temperature, add foaming agent to it and carry out cold mixing, until the mixture is evenly mixed and then granulated by a twin-screw extruder to obtain wood-plastic masterbatch.

[0037] Co-extrusion molding process: th...

Embodiment 2

[0045] Example 2: The preparation method is the same as in Example 1, except that talcum powder, TiCl 4 And NaOH, the molar ratio of cerium nitrate is 1:100:400:1.

Embodiment 3

[0046]Example 3: The preparation method is the same as in Example 1, except that talcum powder, TiCl 4 And NaOH, the molar ratio of cerium nitrate is 1:100:400:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com