Anti-oxidation gold powder decoration film

An anti-oxidation gold and decorative film technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of not bright enough color, affect the decorative effect, gold darkening and greening, etc., and achieve improvement. Physical stability, improved anti-yellowing, good coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

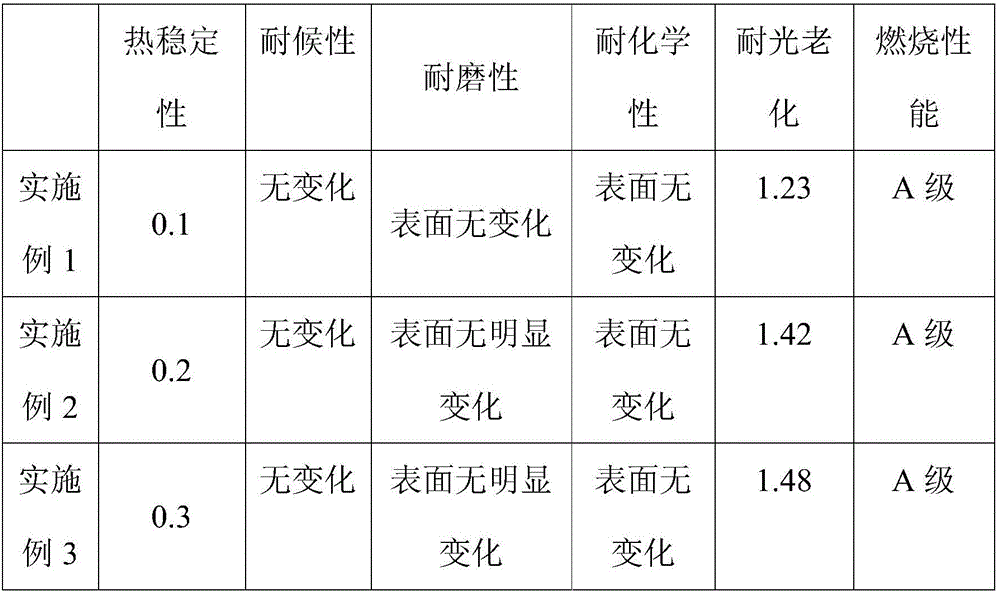

Embodiment 1

[0023] An anti-oxidation gold powder decorative film, the decorative film comprises a mask and a bottom film, and the mask is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin powder, 45 parts of DOTP plasticizer, barium-zinc stabilized 3 parts of stearic acid, 0.1 part of stearic acid, 2.5 parts of anti-oxidation gold pink material with a mesh number of 1500, and 3 parts of liquid flame retardant; the bottom film is prepared from the following raw materials by weight: vinyl chloride resin powder 100 parts parts, 45 parts of DOTP plasticizer, 3 parts of barium zinc stabilizer, 2.5 parts of titanium dioxide powder, 2.5 parts of 1500 mesh anti-oxidation gold powder, and 3 parts of powder flame retardant.

[0024] The decorative film is prepared by the following steps:

[0025] (1) Mask calendering: mask ingredients, high-speed stirring, four-roll calendering and cooling to shape;

[0026] (2) Bottom film calendering: bottom film...

Embodiment 2

[0030] An anti-oxidation gold powder decorative film, the decorative film includes a mask and a bottom film, and the mask is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin powder, 40 parts of DOTP plasticizer, barium-zinc stabilized 1 part of stearic acid, 0.05 part of stearic acid, 1 part of anti-oxidation gold pink material with a mesh number of 1000, and 1 part of liquid flame retardant; the bottom film is prepared from the following raw materials by weight: vinyl chloride resin powder 100 parts, 40 parts of DOTP plasticizer, 1 part of barium-zinc stabilizer, 1 part of titanium dioxide powder, 1 part of anti-oxidation gold powder with a mesh size of 1000 meshes, and 1 part of powder flame retardant.

[0031] The decorative film is prepared by the following steps:

[0032] (1) Mask calendering: mask ingredients, high-speed stirring, four-roll calendering and cooling to shape;

[0033] (2) Bottom film calendering: bottom f...

Embodiment 3

[0037] An anti-oxidation gold powder decorative film, the decorative film comprises a mask and a bottom film, the mask is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin powder, 50 parts of DOTP plasticizer, barium-zinc stabilized 5 parts of stearic acid, 0.2 parts of stearic acid, 5 parts of anti-oxidation gold pink material with mesh number of 2000, and 5 parts of liquid flame retardant; the bottom film is prepared from the following raw materials by weight: vinyl chloride resin powder 100 parts 50 parts of DOTP plasticizer, 5 parts of barium zinc stabilizer, 5 parts of titanium dioxide powder, 5 parts of 2000 mesh anti-oxidation gold pink material, and 5 parts of powder flame retardant.

[0038] The decorative film is prepared by the following steps:

[0039] (1) Mask calendering: mask ingredients, high-speed stirring, four-roll calendering and cooling to shape;

[0040] (2) Bottom film calendering: bottom film batching, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com