Preparation method of graphene-based actuating material for smart clothing

A graphene-based, actuating material technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, can solve the problems of limiting the application of actuating materials, long response time, harsh stimulation conditions, etc. To achieve the effect of controllable deformation degree, rapid response and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

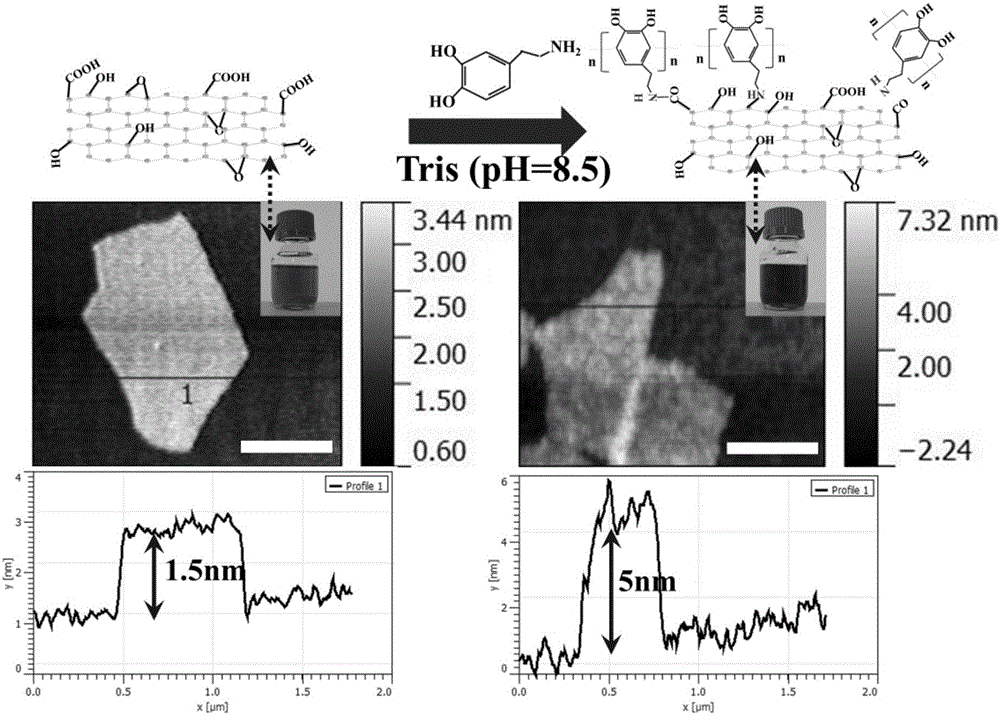

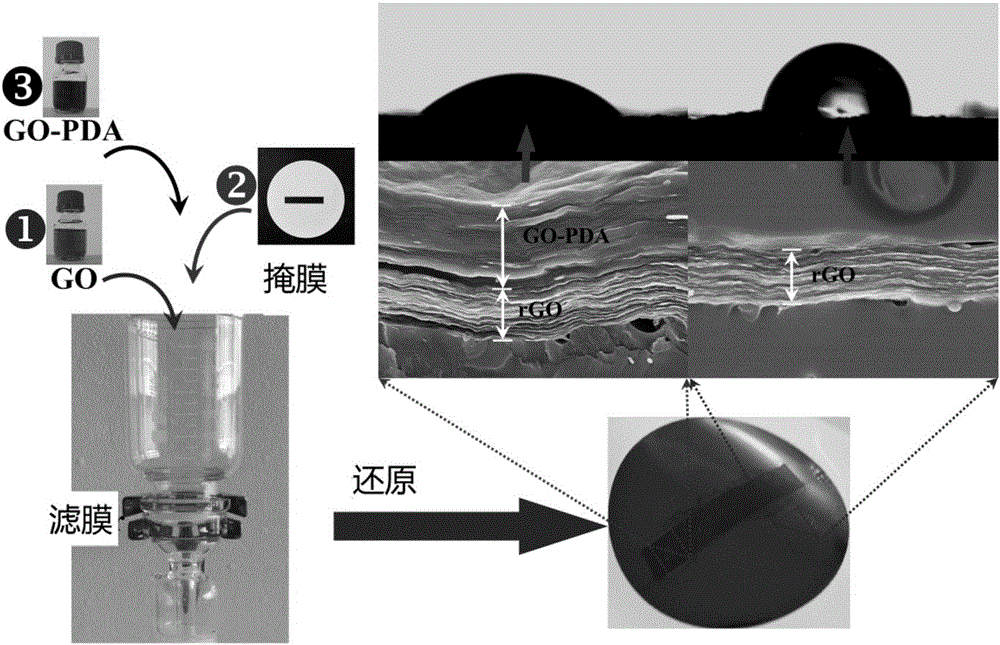

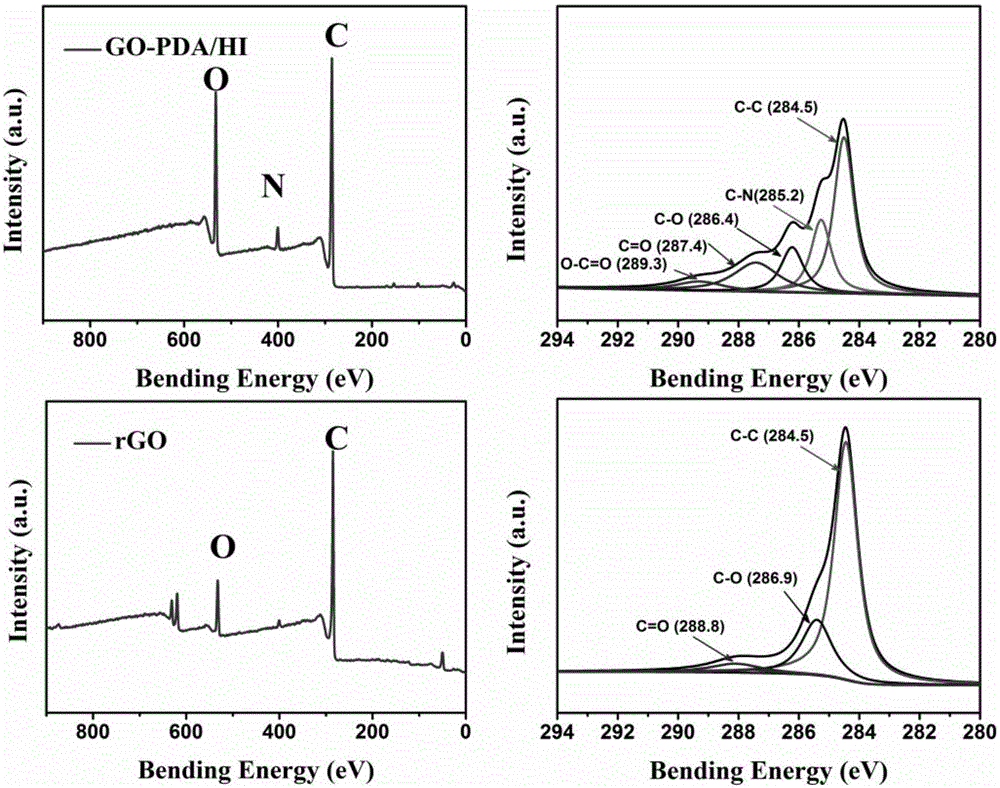

[0037] Graphene oxide is prepared by the method reported in the literature (Journal of the American Chemical Society 1958,80,1339-1339.), 5 mg graphene oxide powder is dispersed in deionized water, and is ultrasonicated for 0.5 hour with a cell pulverizer to obtain brown half Transparent graphene oxide aqueous solution (such as figure 1 Shown), the analysis by scanning probe microscopy shows that the thickness of graphene oxide prepared by this method is about 1nm, which is a single-layer graphene with good quality. 0.05 mg of dopamine powder was added to the graphene oxide dispersion at one time, and magnetically stirred for 1 hour to make the dopamine molecules and the graphene surface functional groups fully and uniformly contact. Then use Tris buffer substance to adjust the pH of the mixed solution to about 8.5, and continue to stir for 6 hours. After the solution changes from brown transparent to black opaque, the self-polymerization grafting reaction is completed, and g...

Embodiment 2

[0039] Graphene oxide was prepared by the method reported in the literature (Journal of the American Chemical Society 1958,80,1339-1339.), disperse 3 mg graphene oxide powder into N,N-dimethylformamide, and use a cell pulverizer to sonicate After 0.5 hour, a brown translucent graphene oxide solution was obtained. Add 0.1 mg of small molecule glycoprotein to the graphene oxide dispersion at one time, stir magnetically for 1 hour, adjust the pH to 8.5, and continue stirring to obtain grafted graphene oxide. Grafted graphene oxide is washed and prepared as a solution or slurry with a concentration of 8mg / mL, and then the grafted graphene oxide is sprayed onto the surface of the polyimide film, due to the hydrophilicity of the grafted graphite oxide properties and the hydrophobicity of polyimide, the two parts of the film show different responses to temperature changes, the grafted graphene oxide part of the film can absorb a large amount of moisture in the air, and the moisture i...

Embodiment 3

[0041] Graphene oxide is prepared by the method reported in the literature ((Journal of the American Chemical Society 1958,80,1339-1339.), 100mg graphene oxide powder is dispersed in deionized water of 50mL, and ultrasonic 1.5 hours is obtained with cell pulverizer. Brown graphene oxide aqueous solution. The above solution is divided into two 50mL solutions, 0.5mg of dopamine powder is added to 50mL graphene oxide dispersion at one time, magnetically stirred for 1 hour, and then the mixed solution is adjusted with Tris buffer substance pH to about 8.5, continue to stir for 6 hours, and the self-polymerization grafting reaction is completed when the solution turns from brown transparent to black. The grafted graphene oxide is washed and prepared as a solution or slurry with a concentration of 25 mg / mL, and then used The wet spinning coagulation bath method blends two kinds of graphite oxide before grafting and after grafting into a fiber, and can controlly program a fiber by con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com