Cooling device in production of water-soluble ammonium polyphosphate

A water-soluble polymerization and cooling device technology, applied in phosphorus compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of inability to directly package and high temperature, and achieve the effect of simple structure and helpful for cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

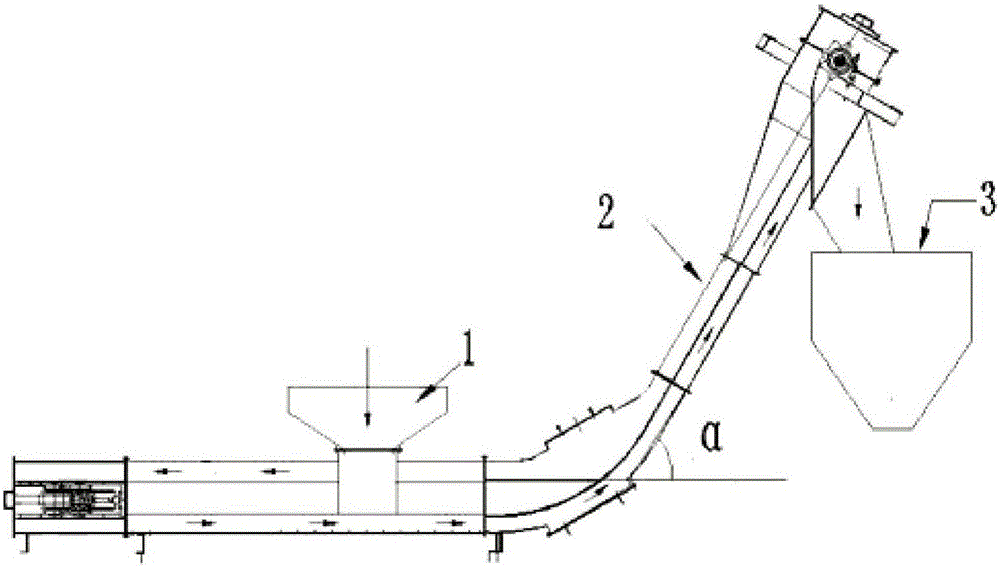

[0014] A cooling device in the production of water-soluble ammonium polyphosphate, comprising a product discharge bin 1 and a finished product packaging bin 3, a scraper machine 2 is arranged between the product discharge bin 1 and the finished product packaging bin 3, and the scraper machine 2 is outsourced Covered with circulating water cooling jacket.

Embodiment 2

[0016] A cooling device in the production of water-soluble ammonium polyphosphate, comprising a product discharge bin 1 and a finished product packaging bin 3, a scraper machine 2 is arranged between the product discharge bin 1 and the finished product packaging bin 3, and the scraper machine 2 is outsourced Covered with circulating water cooling jacket. The scraper machine 2 is composed of two sections, the one connected to the product discharge bin 1 is a horizontal section, and the one connected to the finished product packaging bin 3 is an inclined section, and the angle α between the horizontal section and the inclined section is 30-80°

Embodiment 3

[0018] A cooling device in the production of water-soluble ammonium polyphosphate, comprising a product discharge bin 1 and a finished product packaging bin 3, a scraper machine 2 is arranged between the product discharge bin 1 and the finished product packaging bin 3, and the scraper machine 2 is outsourced Covered with circulating water cooling jacket. The scraper machine 2 is composed of two sections, the one connected to the product discharge bin 1 is a horizontal section, and the one connected to the finished product packaging bin 3 is an inclined section, and the angle α between the horizontal section and the inclined section is 30-80°. The horizontal section is composed of two layers, the upper layer is connected to the product discharge bin 1, and the lower layer is connected to the inclined section after turning.

[0019] The product discharge bin 1 undertakes the production of synthetic ammonium polyphosphate, the temperature of which is 120-180°C. The ammonium polyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com