Electronic differential coupling four-wheel pure electrically-driven electric car

An electronic differential, electric vehicle technology, applied in electric vehicles, electric braking systems, control driving, etc., can solve the problems of space affecting battery layout, low power density and efficiency, large axial installation size, etc., to achieve convenient effect of arrangement, reduced unsprung mass, short axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

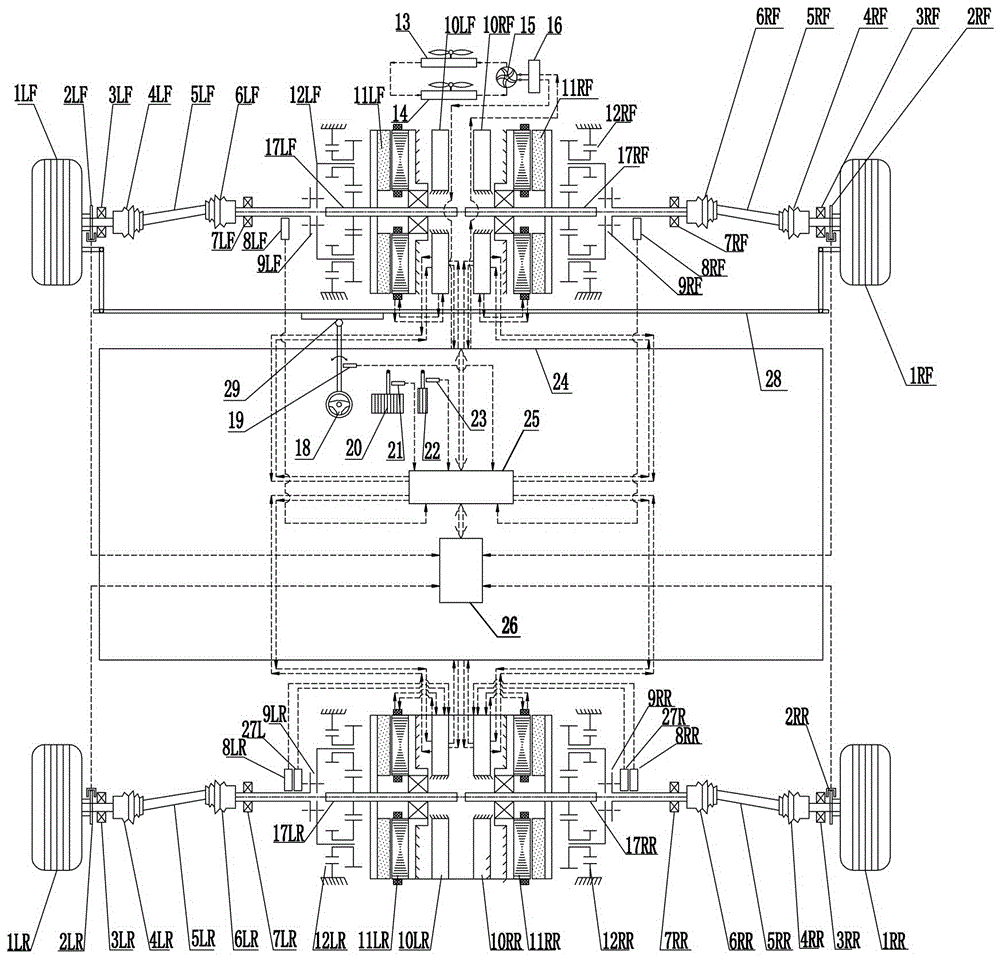

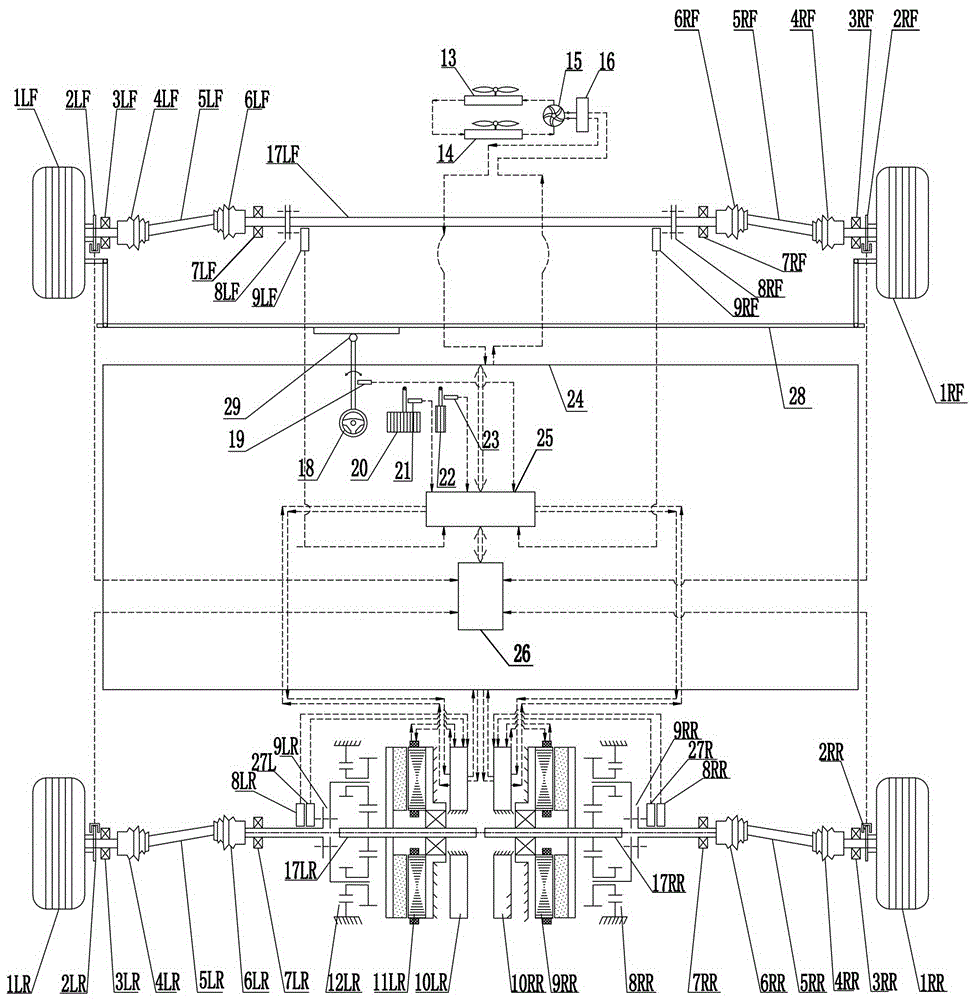

[0029] The invention relates to an electric vehicle driven by electronic differential coupling four-wheel pure electric power. Such as figure 1 with figure 2 As shown, the front and rear axles of the car adopt independent suspension design, and the front axle and the rear axle are divided into two driving half-axles 5LF, 5RF, 5LR, 5RR; in the left front driving half-axle 5LF, planetary deceleration is arranged in sequence from left to right 12LF, disc motor 11LF and disc motor controller 10LF; in the right front drive half bridge 5RF, from right to left, there are planetary reducer 12RF, disc motor 11RF and disc motor controller 10RF in sequence. Taking the disc motors 11LF and 11RF as an example, the main shafts 17LF and 17RF of the disc motors 11LF and 11RF are connected to the input shafts of the sun gears PL1 and PR1 of the planetary reducers 12LF and 12RF thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com