Solar grade crystal silicon slicing technique

A solar-grade, slicing technology, used in work accessories, manufacturing tools, stone processing equipment, etc., can solve the problems of low efficiency, poor efficiency, and high cost, and achieve the effect of reducing production costs, improving benefits, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

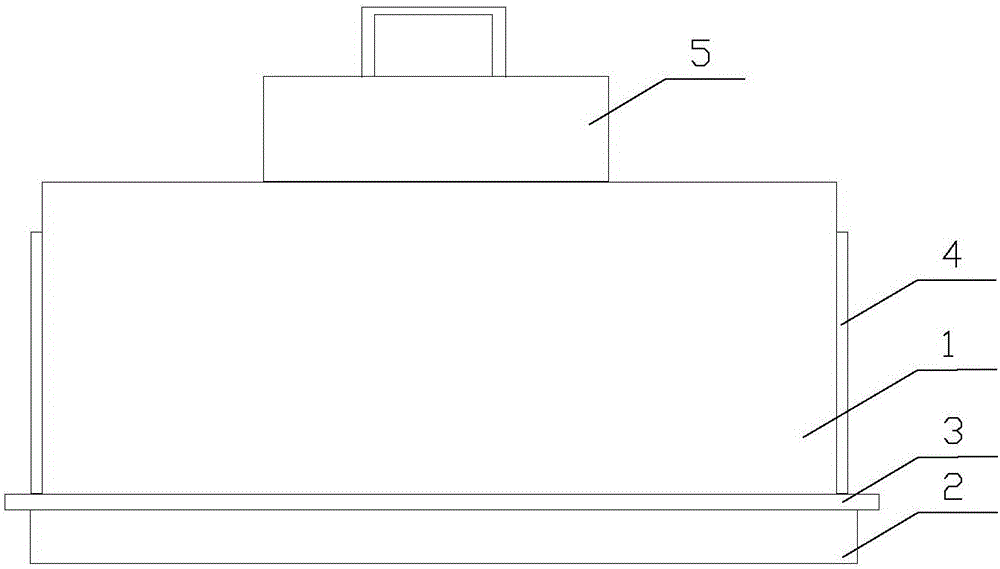

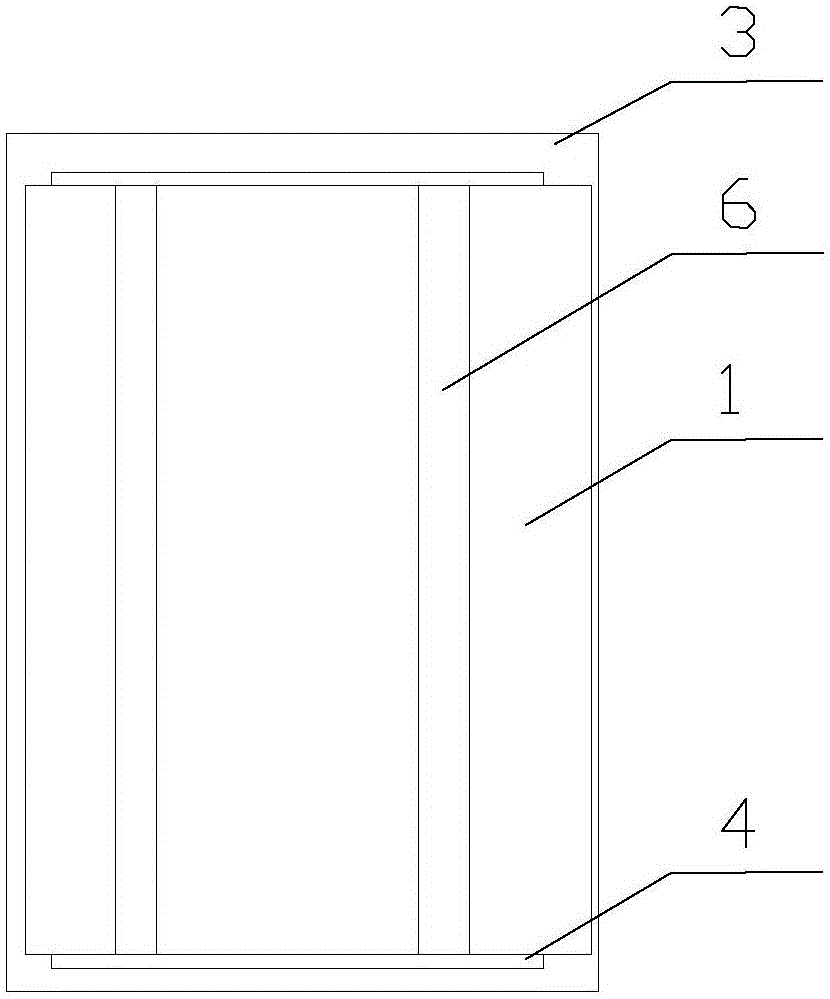

[0017] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as figure 1 combine figure 2 As shown, a solar-grade crystalline silicon slicing process, the specific steps of the process are as follows:

[0019] 1) Fixing, paste and fix the silicon ingot 1 on the sticking table 2, a glass plate 3 is provided between the silicon ingot 1 and the sticking table 2, and baffles 4 are provided on both sides of the silicon ingot 1, and the baffles 4 Stick together with the silicon ingot 1 and fix it on the glass plate 3, the baffle plate 4 is used to fix the balance of the slice, the sticking table 2 is also provided with a briquetting block 5, the weight of the briquetting block 5 is 20-45kg, further briquetting 5 The weight is 25kg, the temperature of the silicon ingot 1 is fixed at 24-28°C, and the humidity is 30-40%; Use glue B in between, first use glue B to fix glass plate 3 and sticking table 2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com