Flexible clamp used for aviation blade

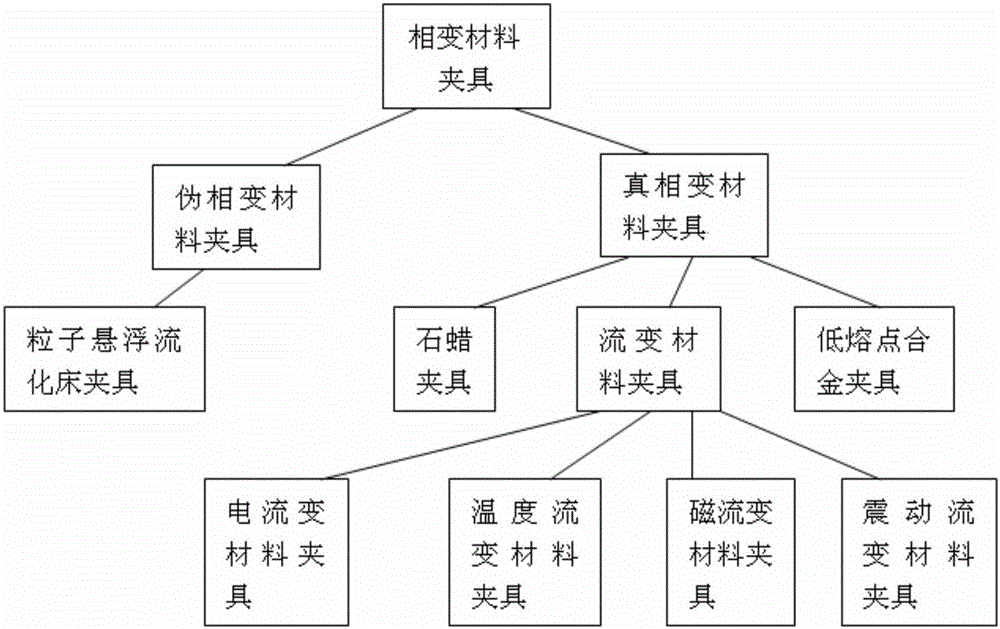

A technology of flexible clamps and blades, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problems of complex and unsuitable clamping of small aviation blades and the weakening of suction cups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] See attached Figure 4 , the flexible fixture of the present embodiment includes four mechanisms, which are blade body supporting mechanism 7, tenon clamping mechanism 8, rotary height adjustment mechanism 9 and angle tilting mechanism 10. By adjusting the working angle of angle tilting mechanism 10, the flexible fixture can Adjust the inclination angle of the blade to adapt to the processing of variable angle inclination, and realize the repair of aviation blades with three-axis CNC machine tools.

[0037] The blade body supporting mechanism 7, the tenon clamping mechanism 8, the rotary height adjustment mechanism 9 and the angle tilting mechanism 10 are described respectively below:

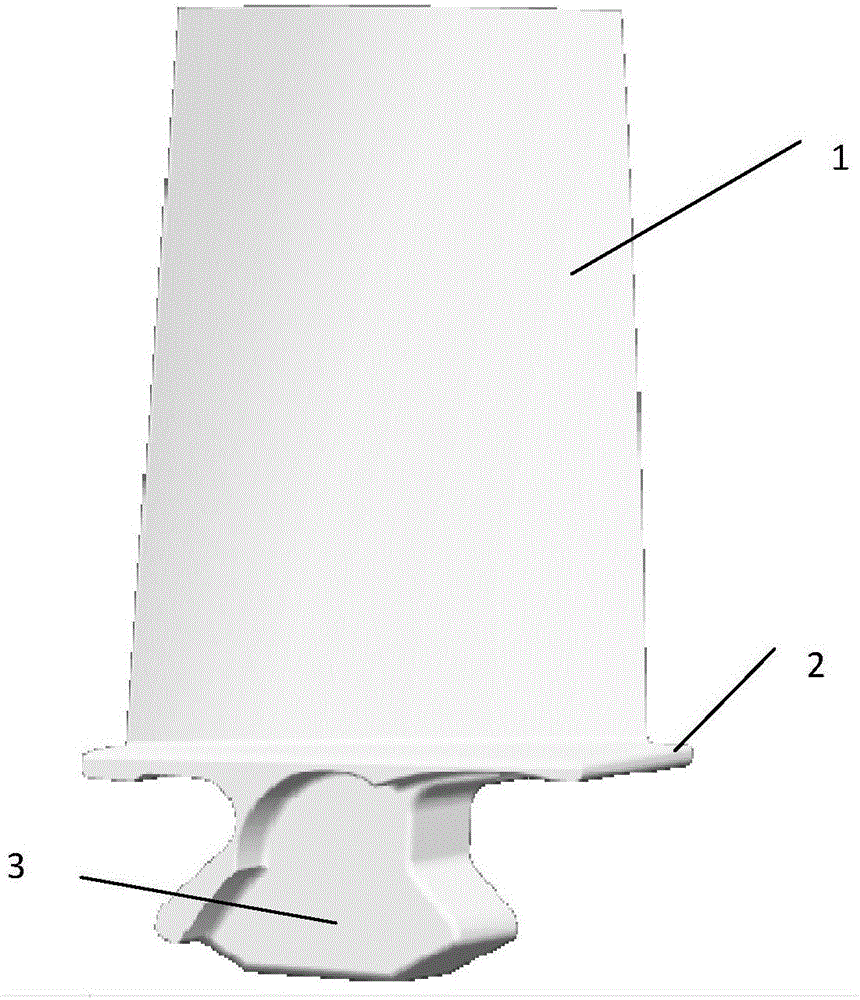

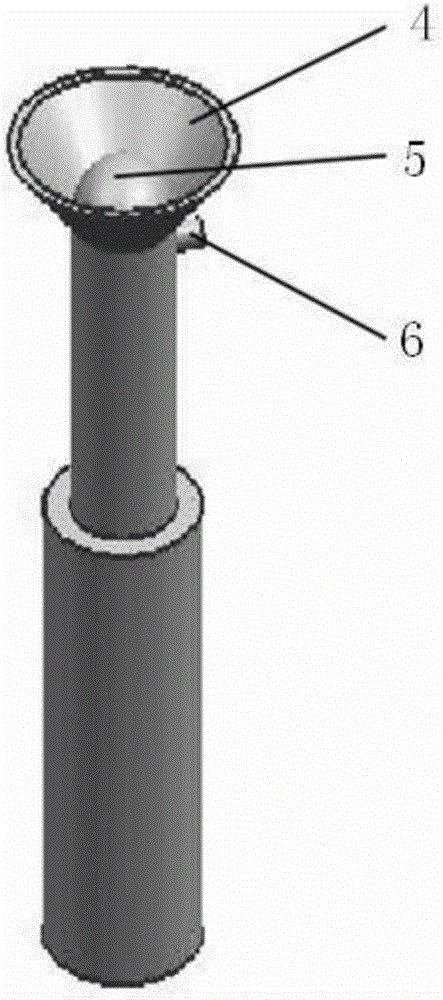

[0038] Refer to attached Figure 5 , the fixture structure of the 7 parts of the airfoil support mechanism, the ejector rod 7.3 cooperates with the densely distributed threaded holes 7.2 on the side plate 7.1 through self-locking threads (the helix angle is less than 4°), and then adjus...

Embodiment 2

[0046] The flexible fixture of this embodiment also has a blade body support mechanism 7, a tenon clamping mechanism 8, a rotary height adjustment mechanism 9, and an angle tilt mechanism 10. By adjusting the working angle of the angle tilt mechanism 10, the flexible fixture can adjust the inclination angle of the blade. In order to adapt to the processing of variable angle and inclination, it is realized to cooperate with the three-axis CNC machine tool to process and repair aviation blades. Although the fixture described in Embodiment 1 can fully meet the processing requirements of the previous "tilting method" three-axis machine tool for machining aviation blades, since the blade basin and the blade back are processed separately during processing, although the angle of inclination of the base can be the same, But the direction of inclination must be opposite, as attached Figure 10 shown. These are two processing processes, in which the same processing origin on the blade ...

Embodiment 3

[0051] The flexible fixture of this embodiment also has a blade body support mechanism 7, a tenon clamping mechanism 8, a rotary height adjustment mechanism 9, and an angle tilt mechanism 10. By adjusting the working angle of the angle tilt mechanism 10, the flexible fixture can adjust the inclination angle of the blade. In order to adapt to the processing of variable angle and inclination, it is realized to cooperate with the three-axis CNC machine tool to process and repair aviation blades.

[0052] Refer again to the attached Figure 5 and 6 , in order to realize the flexible support of the airfoil 1, the airfoil support mechanism 1 specifically includes a side plate 7.1, threaded holes 7.2 uniformly and densely distributed on the side plate, a push rod 7.3 with self-locking threads, and one end of the push rod 7.3 The top bead 7.4 and the top rod 7.3 are inserted into the threaded hole 7.2 on the side plate 7.1, and the top rod 7.3 cooperates with the densely distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com