Manufacturing method of seamless frame of steel wire rope fastening device

A manufacturing method and technology for fasteners, which are applied in the direction of manufacturing tools, appliances for tensioning wires, etc., can solve the problems of poor overall frame strength, easy wear of stressed parts, complicated manufacturing processes, etc., so as to reduce the difficulty of processing and implementation. The effect of low, restoring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A. Preheating treatment

[0056] Preheat the seamless circular steel pipe to 1200°C;

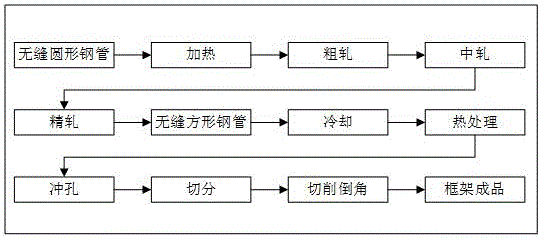

[0057] B. Rolling treatment

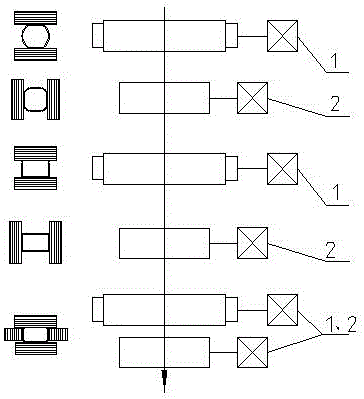

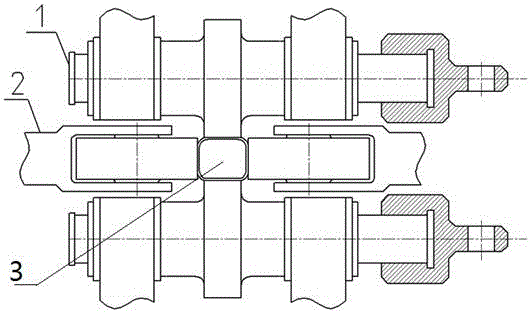

[0058] Rolling the seamless circular steel pipe pre-heated in step A into a seamless square steel pipe; The seamless circular steel pipe is subjected to primary rough rolling in the vertical direction by vertical rolling mill 1, and second rough rolling in the horizontal direction by using horizontal rolling mill 2; 2. Carry out secondary intermediate rolling in the horizontal direction; finally, the seamless steel pipe is subjected to simultaneous vertical and horizontal finishing rolling in the vertical rolling mill 1 and the horizontal rolling mill 2 to obtain the seamless square steel pipe 3 .

[0059] C. cooling treatment

[0060] Naturally cool the rolled seamless square steel pipe to room temperature;

[0061] D. heat treatment

[0062] Anneal the seamless square steel pipe at 400°C;

[0063] E. Punching treatment

[0064] Punch out function...

Embodiment 2

[0069] A. Preheating treatment

[0070] Preheat the seamless circular steel pipe to 1300°C;

[0071] B. Rolling treatment

[0072] Rolling the seamless circular steel pipe pre-heated in step A into a seamless square steel pipe; The seamless circular steel pipe is subjected to primary rough rolling in the vertical direction by vertical rolling mill 1, and second rough rolling in the horizontal direction by using horizontal rolling mill 2; 2. Carry out secondary intermediate rolling in the horizontal direction; finally, the seamless steel pipe is subjected to simultaneous vertical and horizontal finishing rolling in the vertical rolling mill 1 and the horizontal rolling mill 2 to obtain the seamless square steel pipe 3 .

[0073] C. cooling treatment

[0074]Naturally cool the rolled seamless square steel pipe to room temperature;

[0075] D. heat treatment

[0076] Anneal the seamless square steel pipe at 400-600°C;

[0077] E. Punching treatment

[0078] Punch out funct...

Embodiment 3

[0085] A. Preheating treatment

[0086] Preheat the seamless circular steel pipe to 1250°C;

[0087] B. Rolling treatment

[0088] Rolling the seamless circular steel pipe pre-heated in step A into a seamless square steel pipe; The seamless circular steel pipe is subjected to primary rough rolling in the vertical direction by vertical rolling mill 1, and second rough rolling in the horizontal direction by using horizontal rolling mill 2; 2. Carry out secondary intermediate rolling in the horizontal direction; finally, the seamless steel pipe is subjected to vertical and horizontal synchronous finishing rolling in the vertical rolling mill 1 and the horizontal rolling mill 2 at the same time, so as to obtain the seamless square steel pipe 3 .

[0089] C. cooling treatment

[0090] Naturally cool the rolled seamless square steel pipe to room temperature;

[0091] D. heat treatment

[0092] Anneal the seamless square steel pipe at 500°C;

[0093] E. Punching treatment

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| process yield | aaaaa | aaaaa |

| process yield | aaaaa | aaaaa |

| process yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com