Fixed casting ladle for casting

A stationary, ladle technology, used in casting equipment, casting melt containers, manufacturing tools, etc., can solve the problems of high equipment cost, high requirements for controllers and drivers, and low service life of controllers and drivers. Reduced motion and good temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

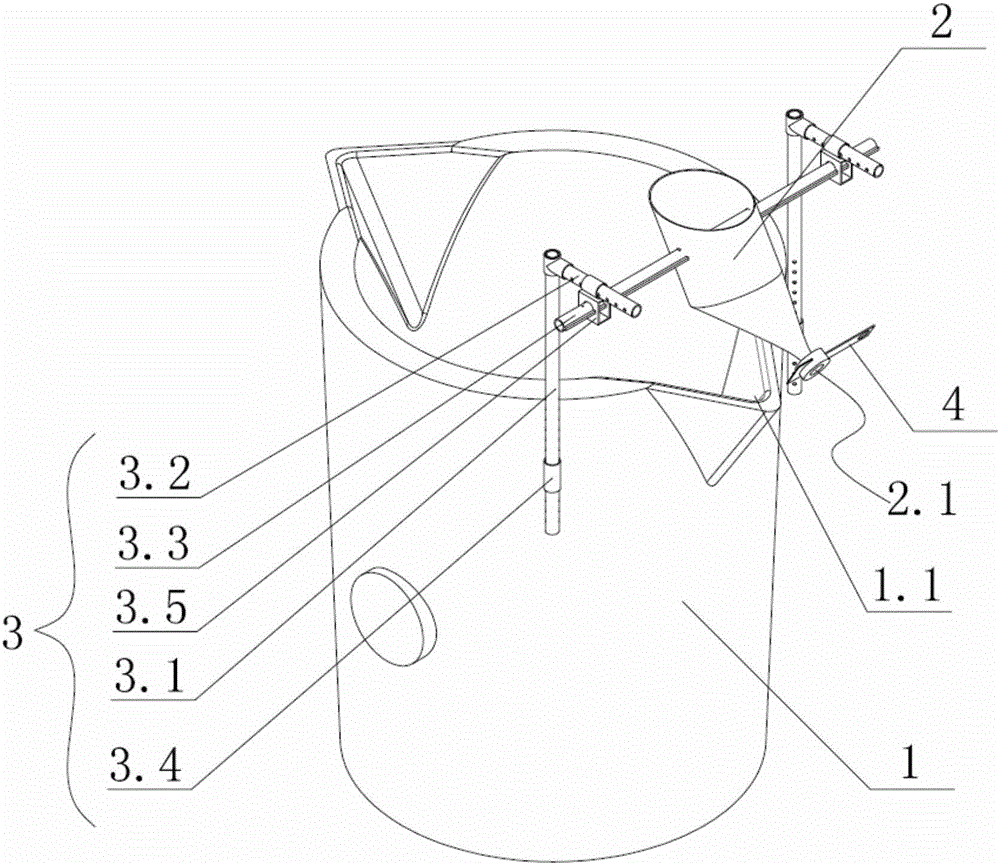

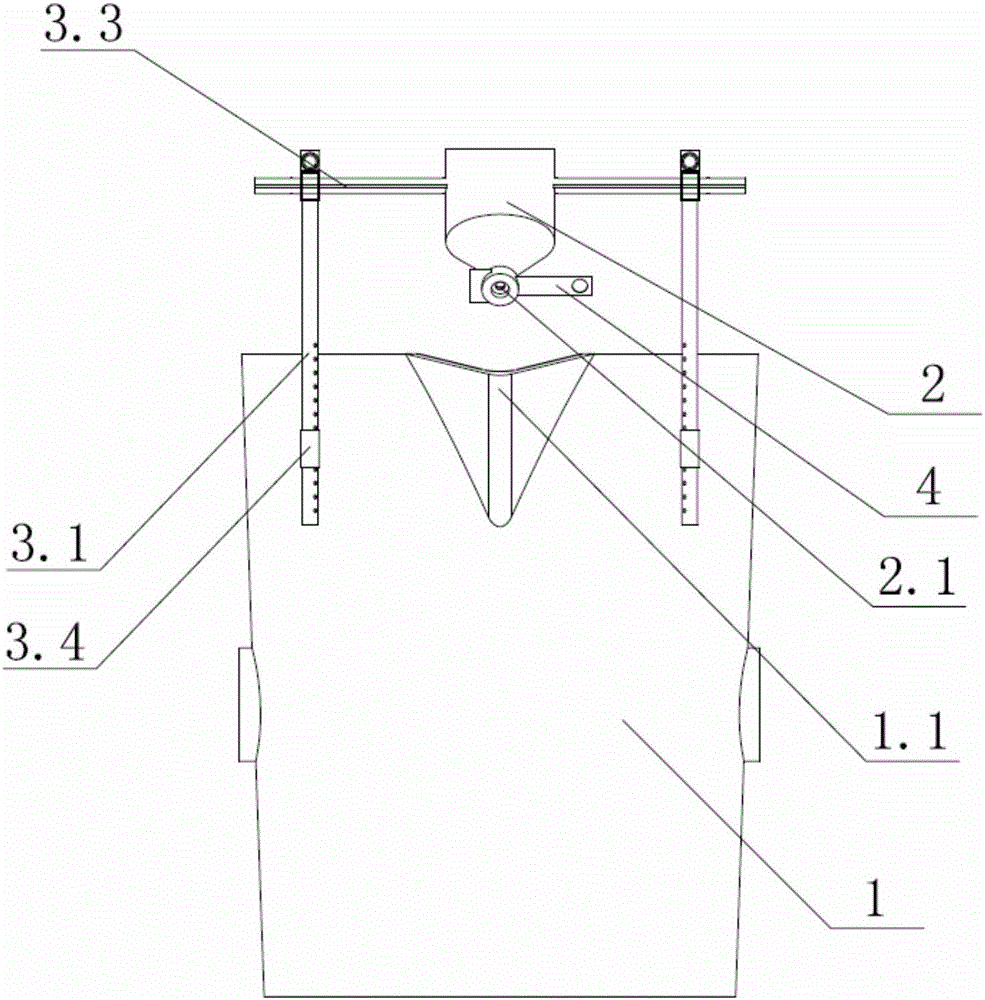

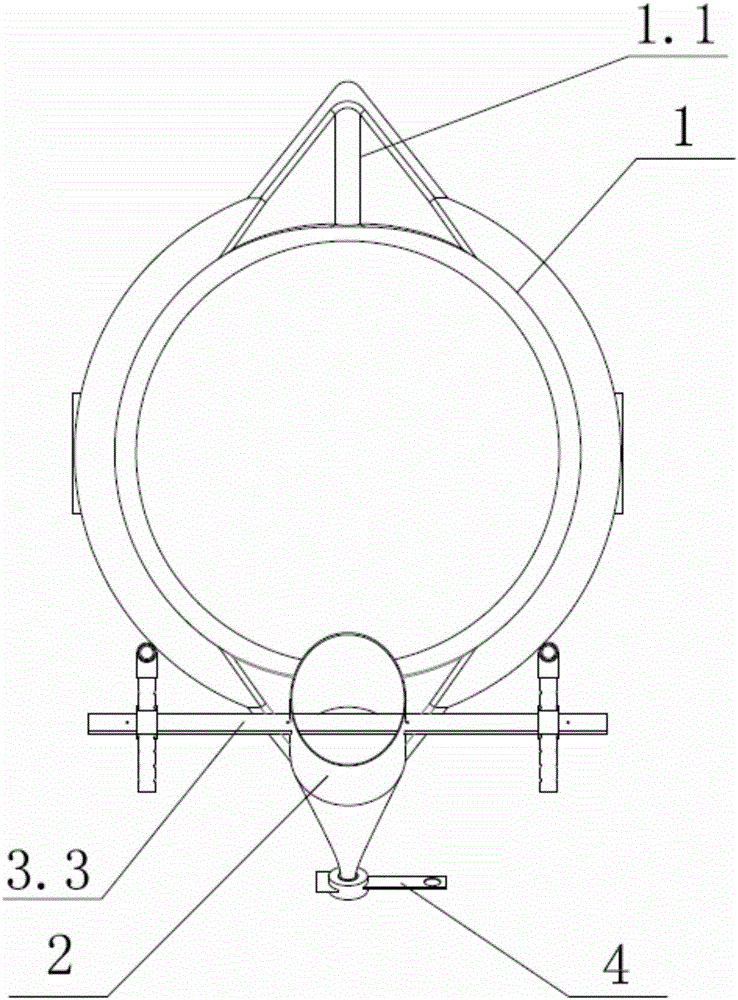

[0025] The invention provides a fixed ladle for casting, which includes a ladle body 1 with a sprue 1.1, and is characterized in that: an inoculation bucket 2 is arranged above the ladle body 1, and the inoculation bucket 2 is connected to the pouring ladle through a bracket 3 The ladle body 1 is fixed, and the outlet 2.1 of the inoculation hopper 2 points out of the ladle body 1 and is located in the area where the gate 1.1 faces.

[0026] The support 3 includes a vertical rod 3.1, a connecting cross rod 3.2 and a load-bearing cross rod 3.3. A sleeve 3.4 is fixed on the outer wall of the ladle body 1, and the lower end of the vertical rod 3.1 is inserted into the sleeve 3.4, and the vertical rod 3.1 is connected to the sleeve. The tubes 3.4 are locked by bolts, one end of the connecting bar 3.2 is fixed to the vertical bar 3.1, and a connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com