Cooling device for high-precision gear forging machining

A gear forging and cooling device technology, which is applied to forging/pressing/hammer devices, heating/cooling equipment, parts of pumping devices for elastic fluid, etc., can solve the problems of product quality reduction, mold deformation, and mold scrapping, etc. , to achieve enhanced cooling effect, low cost, and avoid mold deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

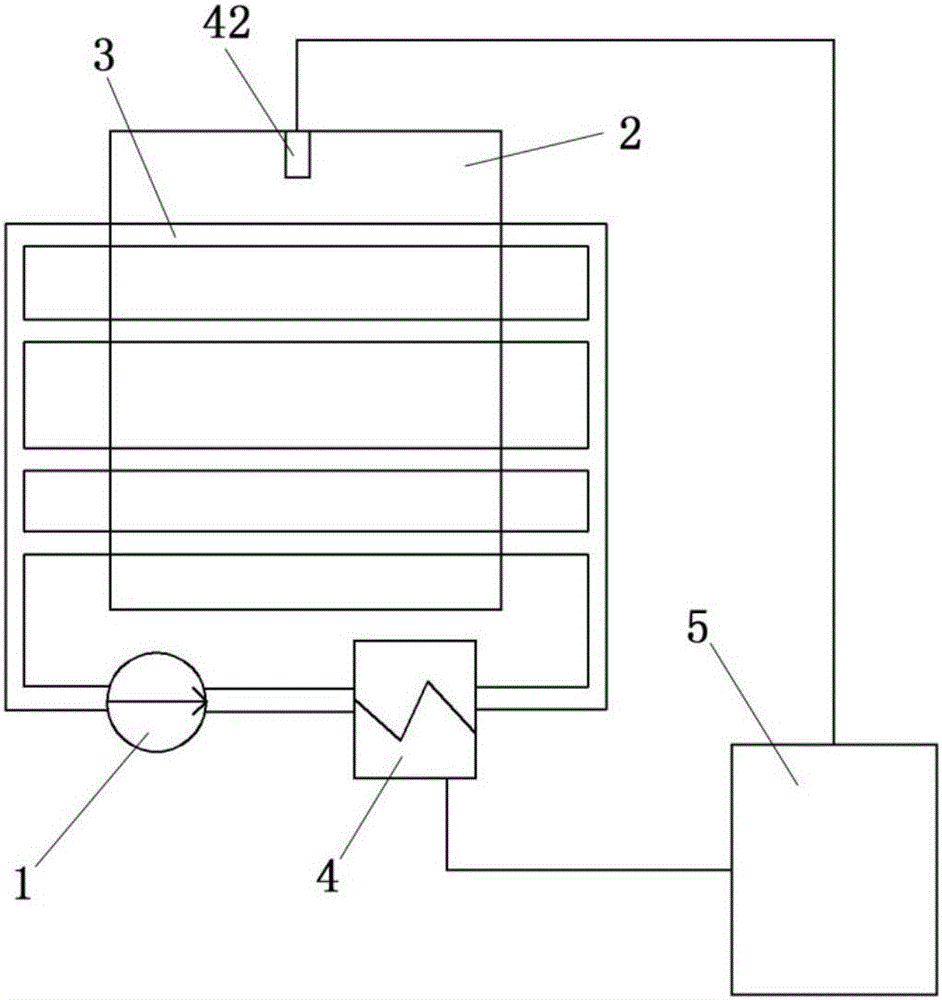

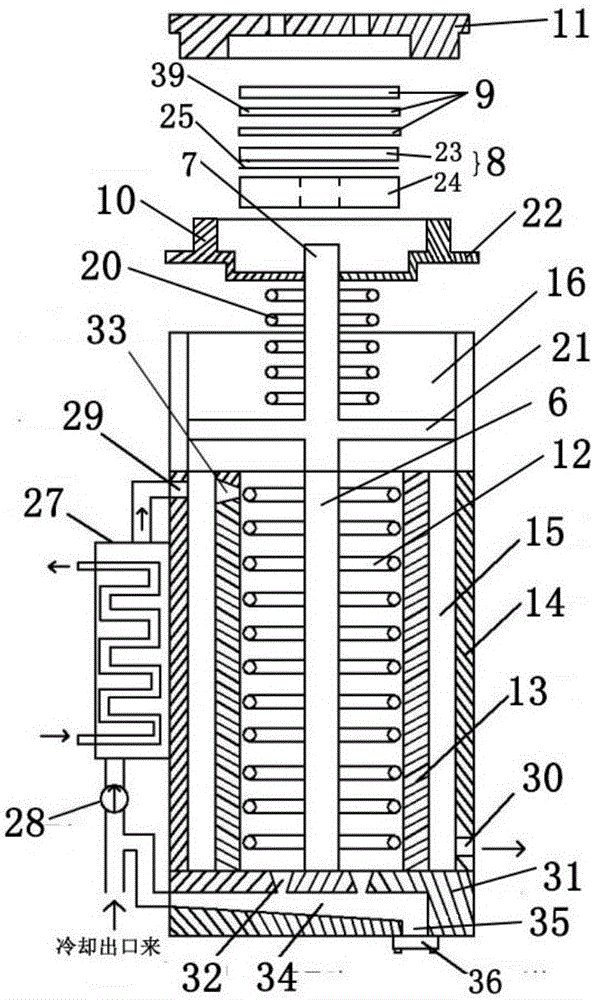

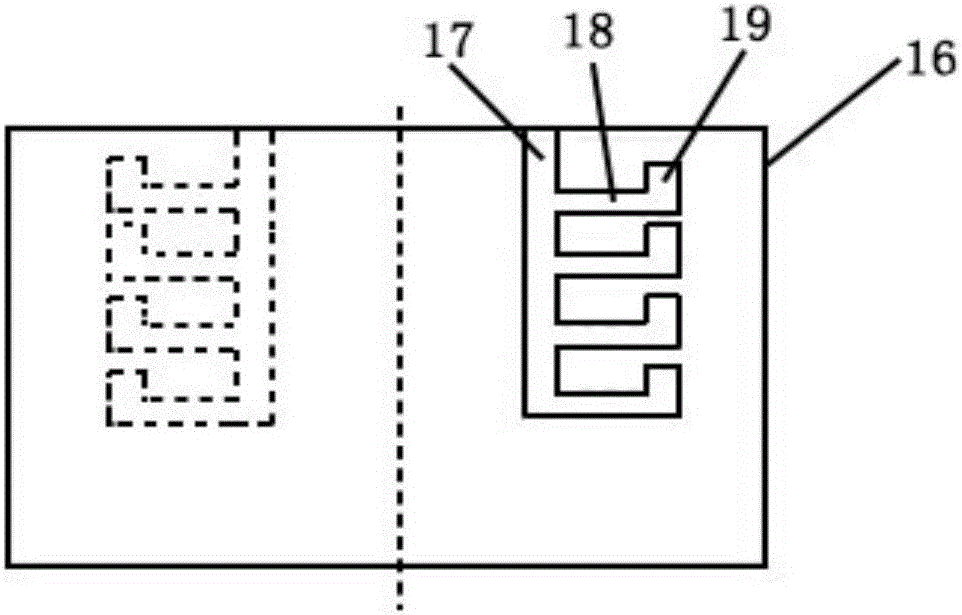

[0030] Such as figure 1 The cooling device for high-precision gear forging shown includes a cooling box 2, a cooling pipe 3, a circulating oil pump, a cooler 4, a refrigerator 5 and a cooling nozzle 42, and the cooling pipes 3 are arranged on the four walls of the cooling box 2. One end of which is connected to the inlet of the circulating oil pump, and the other end is connected to the outlet of the cooler 4; the cold wind produced by the refrigerator 5 enters the cooler 4 to cool the hot oil one way, and the other way passes into the cooling box arranged on the upper part of the cooling box 2. Cooling nozzle 42; the cold oil cooled by the cooler 4 is sent to the cooling pipe 3 to cool the forging mold in the cooling box 2, and then returns to the inlet of the circulating oil pump. The circulating oil pump is a giant magnetostrictive pump 1 . The cooling nozzle 42 is arranged at the center position of the upper part of the cooling box 2 . There are three cooling pipes 3 in ...

Embodiment 2

[0042] Such as figure 1 The cooling device for high-precision gear forging shown includes a cooling box 2, a cooling pipe 3, a circulating oil pump, a cooler 4, a refrigerator 5 and a cooling nozzle 42, and the cooling pipes 3 are arranged on the four walls of the cooling box 2. One end of which is connected to the inlet of the circulating oil pump, and the other end is connected to the outlet of the cooler 4; the cold wind produced by the refrigerator 5 enters the cooler 4 to cool the hot oil one way, and the other way passes into the cooling box arranged on the upper part of the cooling box 2. Cooling nozzle 42; the cold oil cooled by the cooler 4 is sent to the cooling pipe 3 to cool the forging mold in the cooling box 2, and then returns to the inlet of the circulating oil pump. The circulating oil pump is a giant magnetostrictive pump 1 . The cooling nozzle 42 is arranged at the center position of the upper part of the cooling box 2 . There are three cooling pipes 3 in ...

Embodiment 3

[0054] Such as figure 1 The cooling device for high-precision gear forging shown includes a cooling box 2, a cooling pipe 3, a circulating oil pump, a cooler 4, a refrigerator 5 and a cooling nozzle 42, and the cooling pipes 3 are arranged on the four walls of the cooling box 2. One end of which is connected to the inlet of the circulating oil pump, and the other end is connected to the outlet of the cooler 4; the cold wind produced by the refrigerator 5 enters the cooler 4 to cool the hot oil one way, and the other way passes into the cooling box arranged on the upper part of the cooling box 2. Cooling nozzle 42; the cold oil cooled by the cooler 4 is sent to the cooling pipe 3 to cool the forging mold in the cooling box 2, and then returns to the inlet of the circulating oil pump. The circulating oil pump is a giant magnetostrictive pump 1 . The cooling nozzle 42 is arranged at the center position of the upper part of the cooling box 2 . There are three cooling pipes 3 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com