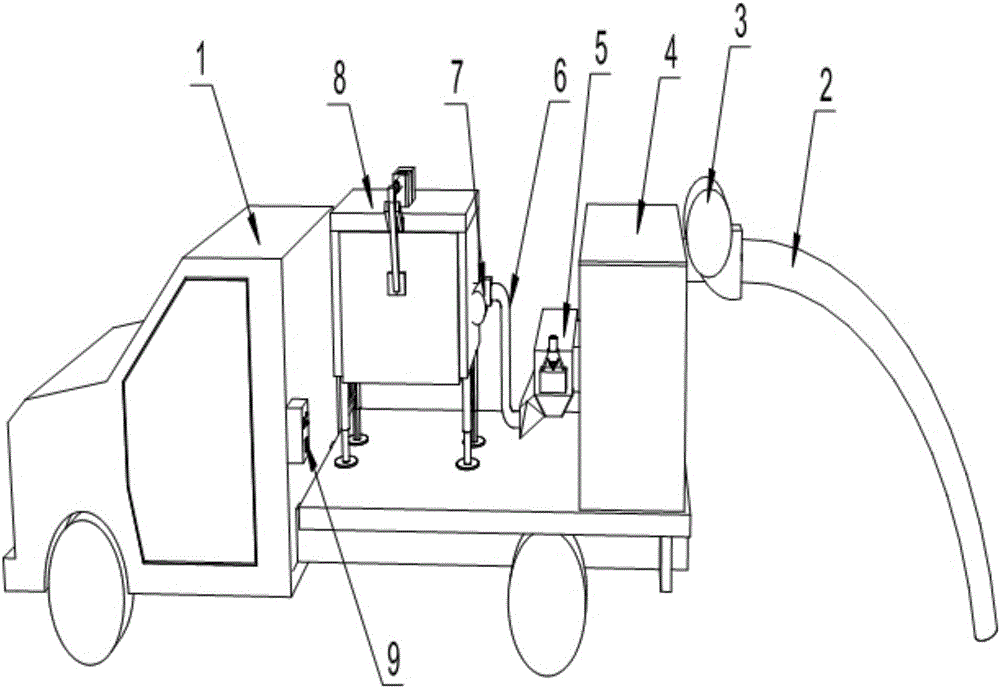

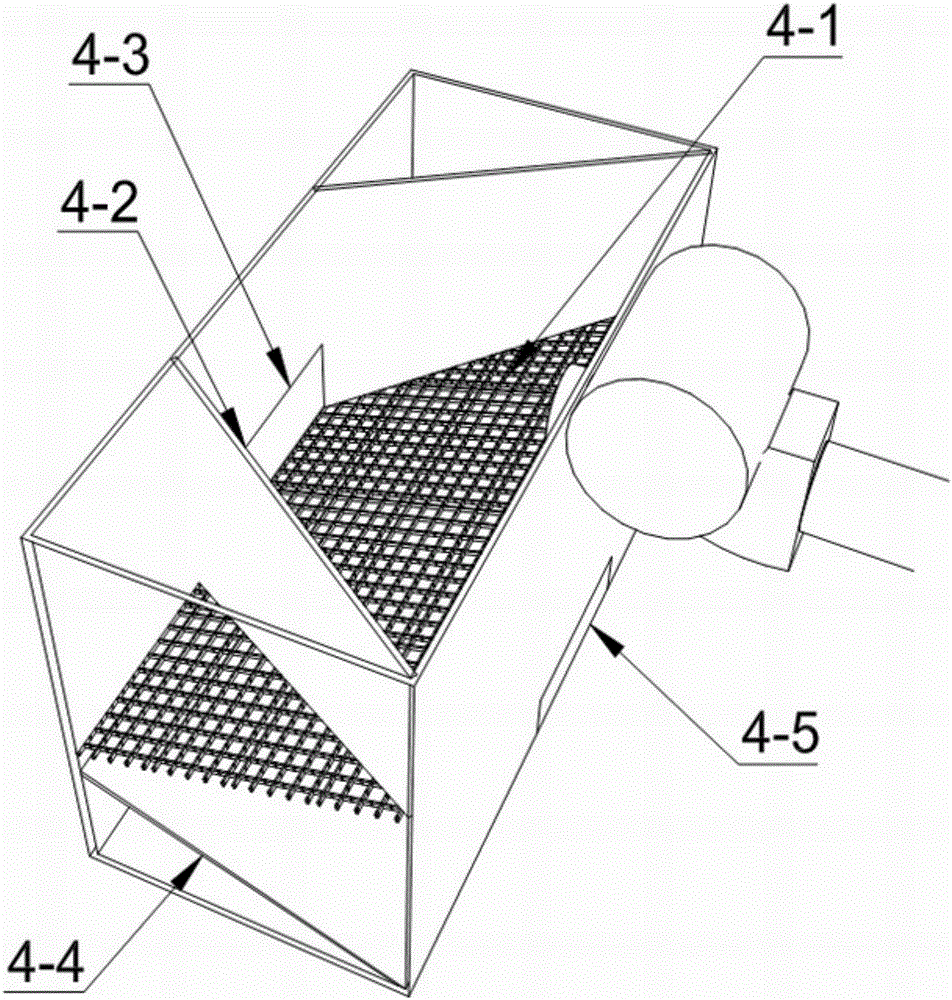

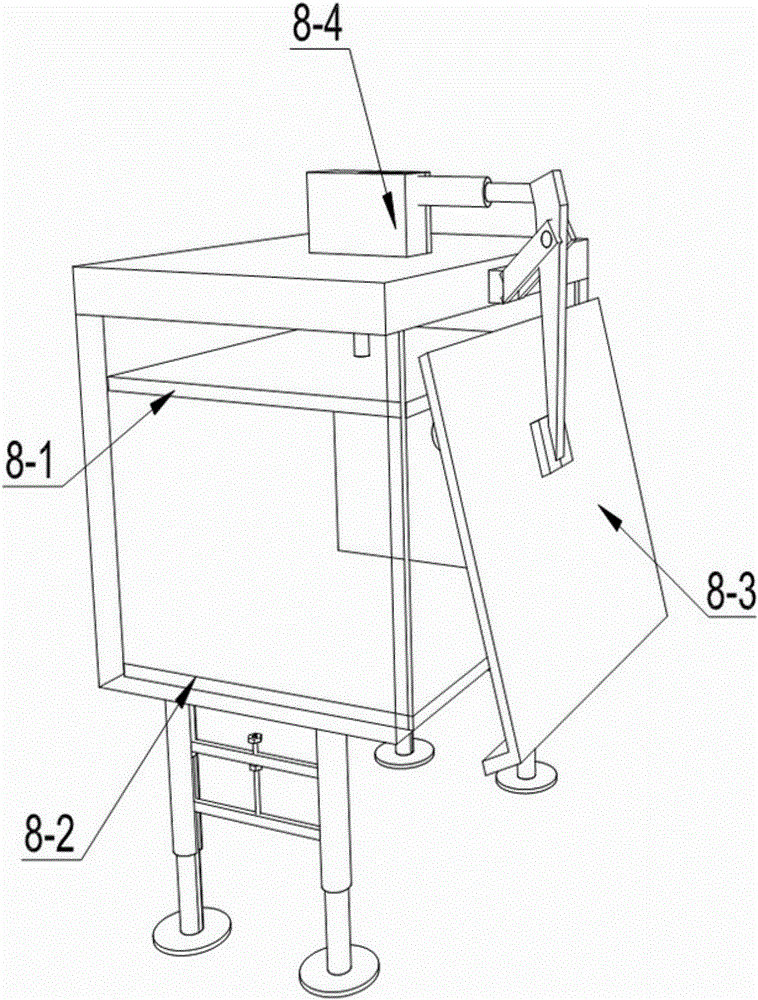

Vehicle-mounted type leaf recycling device and working method thereof

A vehicle-mounted, leaf-based technology, applied in chemical instruments and methods, manufacturing tools, transportation and packaging, etc., can solve problems such as poor utilization rate and long production cycle, and achieve scientific structure, flexible and convenient use, and good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Manufacture the leaf collection pipe 2 of the present invention according to the following steps, and in parts by weight:

[0046] Step 1. Add 400 parts of ultrapure water with a conductivity of 0.10μS / cm into the reactor, start the stirrer in the reactor at a speed of 50rpm, and start the heating pump to raise the temperature in the reactor to 60°C; 6 parts of p-nitrobenzenesulfonyl acetate, 6 parts of ethyl γ-chloroacetoacetate, 6 parts of methyl p-tert-butylphenylacetate, stir until completely dissolved, adjust the pH value to 5.5, and adjust the speed of the agitator to to 100rpm, the temperature is 100°C, and the esterification reaction takes 4 hours;

[0047] Step 2, take 6 parts of ethyl m-aminobenzoate and 6 parts of methyl m-dibutylaminobenzoate and pulverize, the powder particle size is 40 mesh; add 24 parts of nano-scale rhodium borate and mix evenly, spread it on the tray, flat The thickness of the paving is 11mm, and the alpha rays with a dose of 0.2kGy an...

Embodiment 2

[0053] Manufacture the leaf collection pipe 2 of the present invention according to the following steps, and in parts by weight:

[0054] Step 1. Add 600 parts of ultrapure water with a conductivity of 2.40μS / cm into the reactor, start the stirrer in the reactor at a speed of 60rpm, and start the heating pump to raise the temperature in the reactor to 70°C; add in sequence 15 parts of p-nitrobenzenesulfonyl acetate, 15 parts of ethyl γ-chloroacetoacetate, 15 parts of methyl p-tert-butylphenylacetate, stir until completely dissolved, adjust the pH value to 6.5, and adjust the speed of the agitator to to 110rpm, the temperature is 110°C, and the esterification reaction is 10 hours;

[0055] Step 2, take 15 parts of ethyl m-aminobenzoate and 15 parts of methyl m-dibutylaminobenzoate and pulverize, the powder particle size is 80 mesh; add 30 parts of nano-scale rhodium borate and mix evenly, spread it on the tray, flat The thickness of the paving is 21mm, and the dose is 1.2kGy, ...

Embodiment 3

[0061] Manufacture the leaf collection pipe 2 of the present invention according to the following steps, and in parts by weight:

[0062] Step 1. Add 500 parts of ultrapure water with a conductivity of 1.40μS / cm into the reactor, start the stirrer in the reactor at a speed of 55rpm, and start the heating pump to raise the temperature in the reactor to 65°C; 9 parts of p-nitrobenzenesulfonyl acetate, 9 parts of ethyl γ-chloroacetoacetate, 9 parts of methyl p-tert-butylphenylacetate, stir until completely dissolved, adjust the pH value to 5.9, and adjust the speed of the agitator to To 108rpm, the temperature is 108°C, and the esterification reaction is 7 hours;

[0063] Step 2, take 9 parts of ethyl m-aminobenzoate and 9 parts of methyl m-dibutylaminobenzoate and pulverize, the powder particle size is 60 mesh; add 28 parts of nano-scale rhodium borate and mix evenly, spread it on the tray, flat The thickness of the pavement is 16mm, and the alpha ray with a dose of 0.7kGy and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com