Ag-TiO2 nano fiber as well as preparation and application thereof

A nanofiber and glass fiber technology, applied in the application field of catalysts, can solve the problems of low utilization rate of visible light, easy recombination of electrons and holes, etc., and achieve the effect of improving photocatalytic hydrogen production capacity, process controllable, and inhibiting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Ag-TiO of the present invention 2 The preparation method of nanofiber includes the following steps:

[0044] (1) Sol-gel method: Dissolve tetrabutyl titanate, PVP, and acetic acid in absolute ethanol, stir evenly to make light yellow solution A, then dissolve a certain amount of silver nitrate in deionized water at room temperature, and stir evenly Make solution B. Drop solution B into solution A drop by drop at room temperature, and continue stirring until a transparent yellow solution with a certain viscosity is formed;

[0045] (2) Electrospinning method: Ultrasound the solution prepared in step (1), and then inject it into a 5ml syringe. Use a stainless steel needle with an inner diameter of 0.7mm to push the syringe at 0.2 / min. The distance between the needle and the receiving board is 15cm, and the voltage is 16kv. Finally, Ag-TiO with a diameter of 80-100um is spun 2 Nanofibers are calcined at a temperature of 440°C.

[0046] The calcination time in step (2) is 2 hou...

Embodiment 1

[0051] Example 1 Prepared 1% Ag-TiO 2 Nanofiber (Ag in Ag-TiO 2 (The mass percentage of nanofibers is 1%)

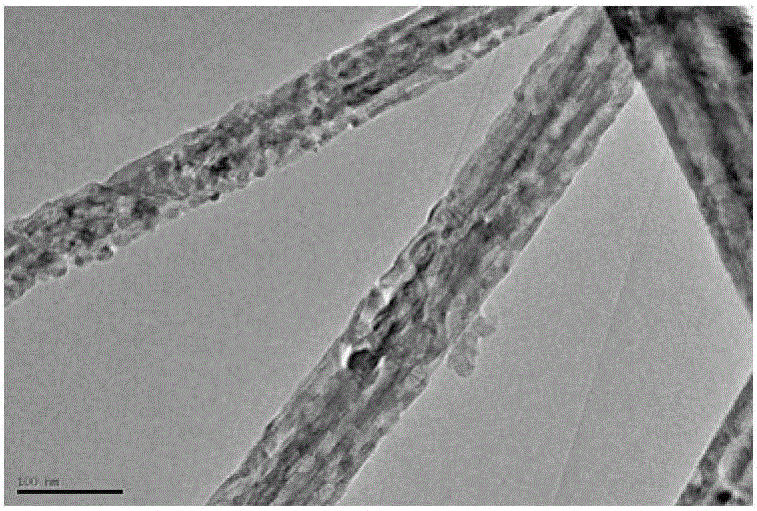

[0052] Such as figure 1 As shown, the resulting 1% Ag / TiO 2 Electronic scanning transmission image of nanofibers, the average diameter of nanofibers is 56.55nm.

Embodiment 2

[0053] Example 2 Prepared 2% Ag / TiO 2 Nanofiber (Ag in Ag-TiO 2 The mass percentage of nanofibers is 2%)

[0054] Such as figure 2 As shown, the resulting 2% Ag / TiO 2 Electronic scanning transmission image of nanofibers, the average diameter of nanofibers is 66.53nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com