Calculation model for design and operation of ammonia process desulfurization spray tower and optimized regulation method

A technology of ammonia desulfurization and calculation model, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., and can solve problems such as inability to meet technical requirements and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

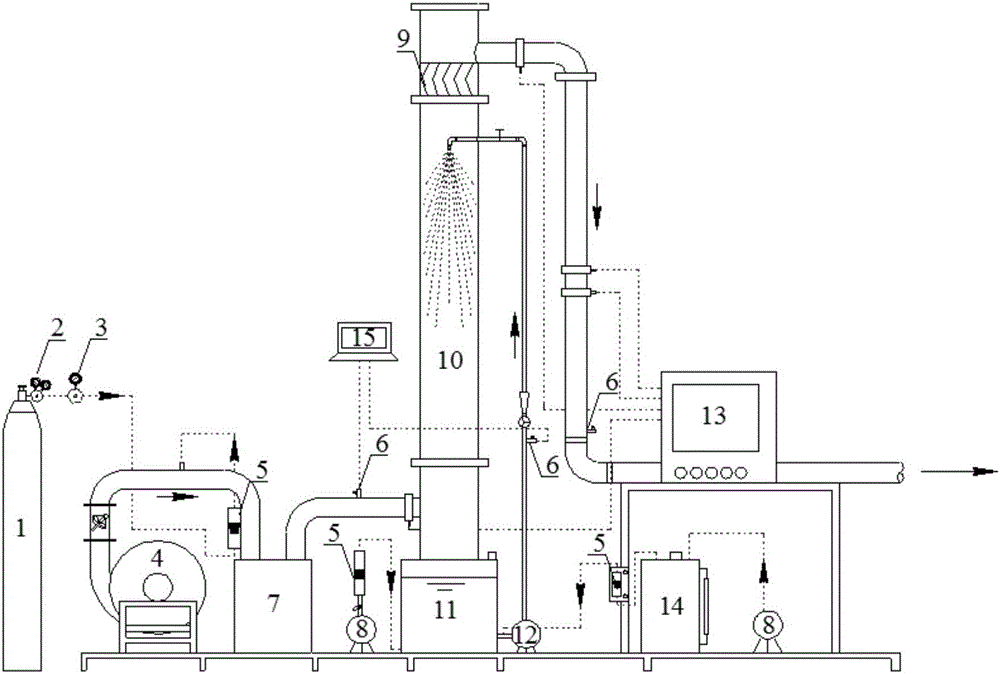

[0117] The ammonia desulfurization spray tower experimental system of the present embodiment is as follows figure 1 As shown, the diameter D of the spray tower is 0.3m, and the height Z of the absorption zone is 2.0m. The ammonia method desulfurization spray tower system includes a spray tower 10, the inside of the spray tower 10 includes a demister area, a spray area and a slurry tank 11 from top to bottom, and the demist area is provided with a demister 9, and the demister The top of the device 9 is provided with a flue gas outlet, and the flue gas outlet is connected with the tail gas discharge pipe, and the tail gas discharge pipe is provided with a control cabinet 13 . The spray area is provided with a spray pipe, and the water inlet of the spray pipe communicates with the bottom of the slurry tank 11 through a circulation pipe and a circulation pump 12 . The bottom of the slurry tank 11 is also connected to the air pump 8 through a pipeline. from SO 2 SO in cylinder 1...

Embodiment 2

[0197] A calculation model for the design and operation of the ammonia-based desulfurization spray tower in this embodiment. The model is firstly based on the characteristics of the spray tower ammonia-based flue gas desulfurization process, and the pH value and flue gas flow rate u are selected. g And the liquid-gas ratio L / Q is used as a parameter to calculate different pH values and flue gas flow rates u g Ammonia desulfurization of SO under the condition of liquid-gas ratio L / Q 2 Absorb mass transfer rate, and use numerical fitting method to construct a universally applicable ammonia desulfurization SO 2 The expression of the absorption mass transfer coefficient; then analyze the ion charge conservation and element material conservation in the liquid phase, according to the NH 3 -SO 2 -H 2 The thermodynamic characteristics of O system and the principle of ion balance to establish SO in the spray tower 2 Gas-liquid dynamic equilibrium relationship during absorption, c...

Embodiment 3

[0249] use as figure 1 The shown spray tower ammonia desulfurization experimental system is tested, the pH of the slurry is controlled to be 3, and the flue gas flow rate is u g is 2.56m / s, and the liquid-gas ratio is 1.5L / m 3 , the experimentally measured SO at the inlet of the spray tower 2 Concentration is 360ppm, SO at the outlet of spray tower 2 The concentration is 171ppm, according to the formula: Calculated to get SO 2 The removal efficiency is 52.5%.

[0250] Set the experimental condition pH to 3, u g is 2.56m / s, and the liquid-gas ratio is 1.5L / m 3 , into the ammonia desulfurization SO established in Example 2 2 In the absorption model, according to the steps in Example 2, the calculation of SO 2 The removal efficiency is 68.86%. The error between the two is 23.76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com