110kV/10kV and 110kV/35kV two pre-installed integrated intelligent substations

An intelligent substation, 1.110kv technology, applied in distribution substations, panel/switch station circuit devices, transformer/inductor components, etc., can solve problems such as large project investment, high building structure, and damage to service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

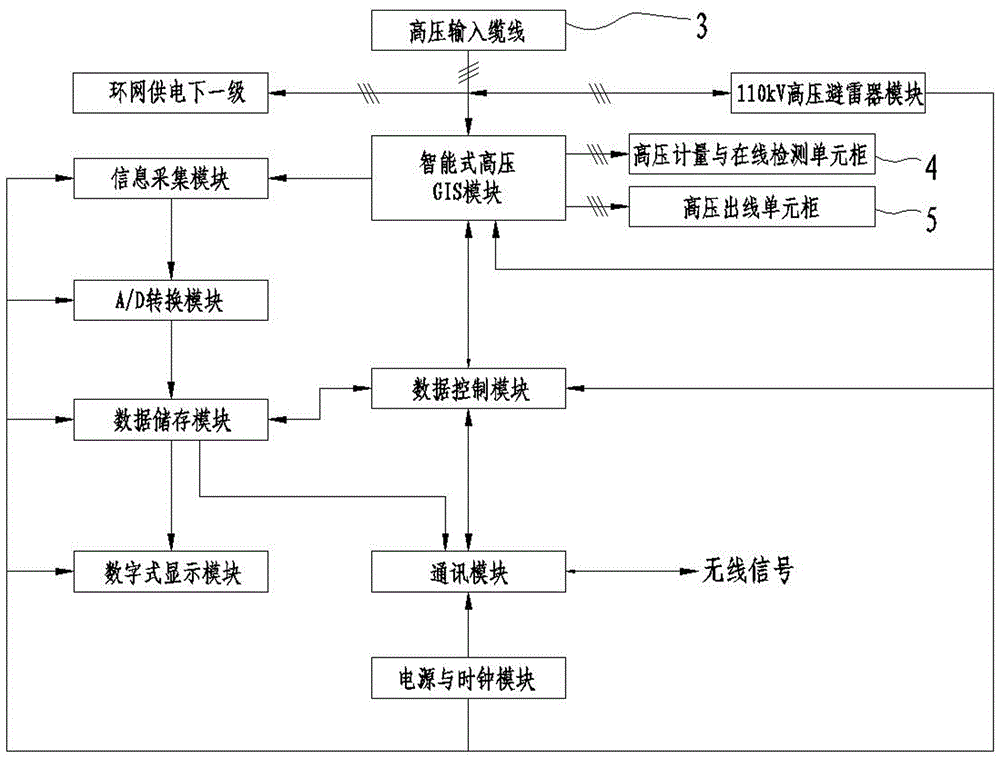

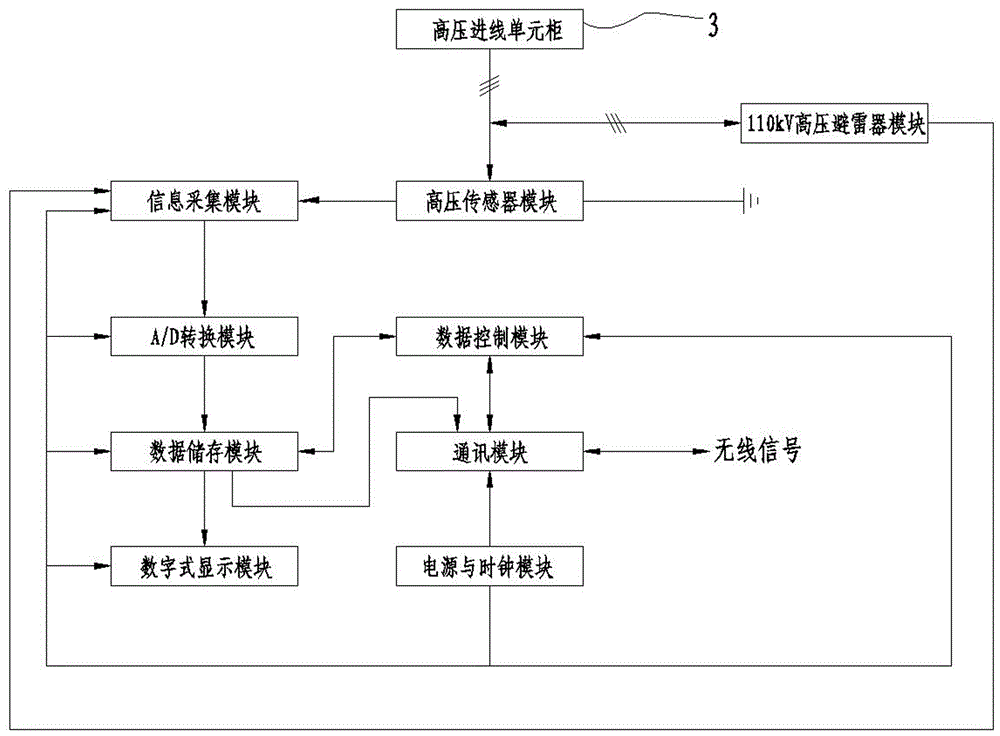

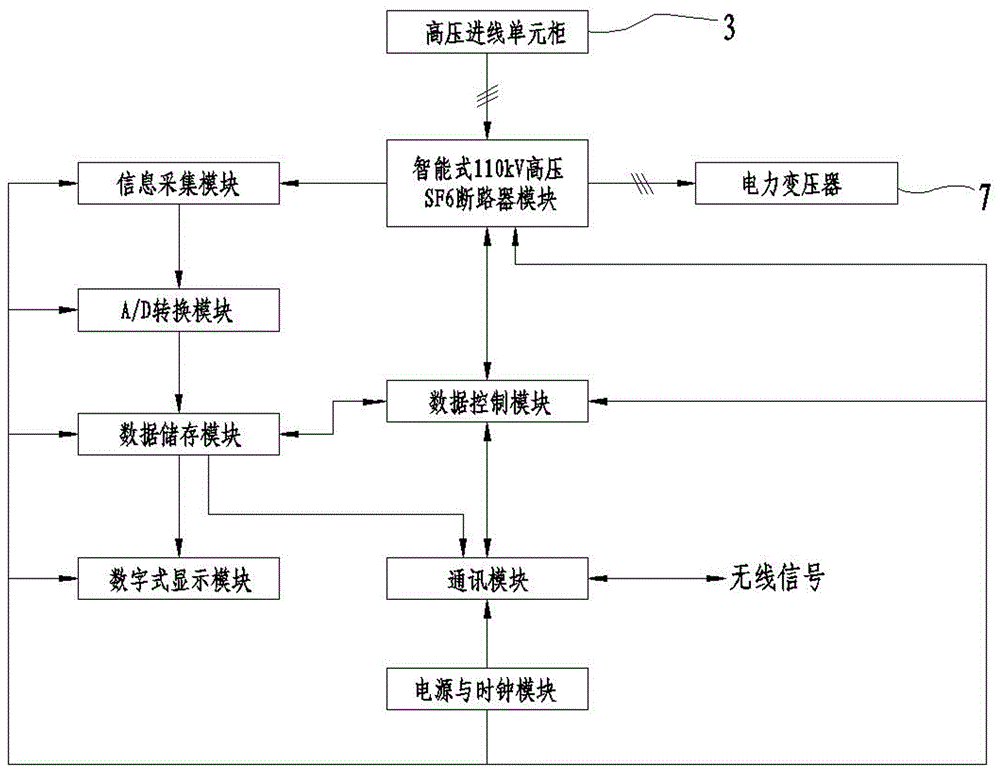

[0030] like figure 1 and figure 2 As shown, the 110kV / 10kV prefabricated integrated intelligent substation includes 110kV high-voltage input cable 1, 110kV combined electrical appliance GIS 2, 110kV / 10kV power transformer 7, and 10kV low-voltage cabinet 8. The 110kV high-voltage input cable 1 and The 110kV combined electrical appliance GIS 2 is connected, the 110kV combined electrical appliance GIS 2 is connected to the 110kV / 10kV transformer 7, the 110kV / 10kV transformer 7 is connected to the 10kV low-voltage cabinet 8, and the 10kV low-voltage cabinet 8 is connected to the 10kV user; the 110kV The combined electrical appliance GIS 2 is three-phase, and is composed of 110kV high-voltage incoming line unit 3, 110kV high-voltage metering and online monitoring unit 4, 110kV high-voltage outgoing line unit 5 and 110kV high-voltage bus-connection unit 6 combined by various intelligent module building blocks. The primary main line of the 110kV high-voltage incoming line unit 3 is...

Embodiment 2

[0044] like figure 1 and figure 2 As shown, the 110kV / 35kV prefabricated integrated intelligent substation includes 110kV high-voltage input cable 1, 110kV combined electrical appliance GIS 2, 110kV / 35kV power transformer 7, and 35kV low-voltage cabinet 8. The 110kV high-voltage input cable 1 and The 110kV combined electrical appliance GIS 2 is connected, the 110kV combined electrical appliance GIS 2 is connected to the 110kV / 35kV transformer 7, the 110kV / 35kV transformer 7 is connected to the 35kV low-voltage cabinet 8, the 35kV low-voltage cabinet 8 is connected to the 10kV user, and the 110kV The combined electrical appliance GIS 2 is three-phase, and is composed of 110kV high-voltage incoming line unit 3, 110kV high-voltage metering and online monitoring unit 4, 110kV high-voltage outgoing line unit 5 and 110kV high-voltage bus-connection unit 6 combined by various intelligent module building blocks. The primary main line of the 110kV high-voltage incoming line unit 3 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com