Small multi-core high-voltage connector

A high-voltage connector, small technology, applied in the direction of connection, two-part connection device, device to prevent wrong connection, etc., can solve the problems of heavy product weight, large volume, limited internal space of equipment, etc. Effects of flame retardancy and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

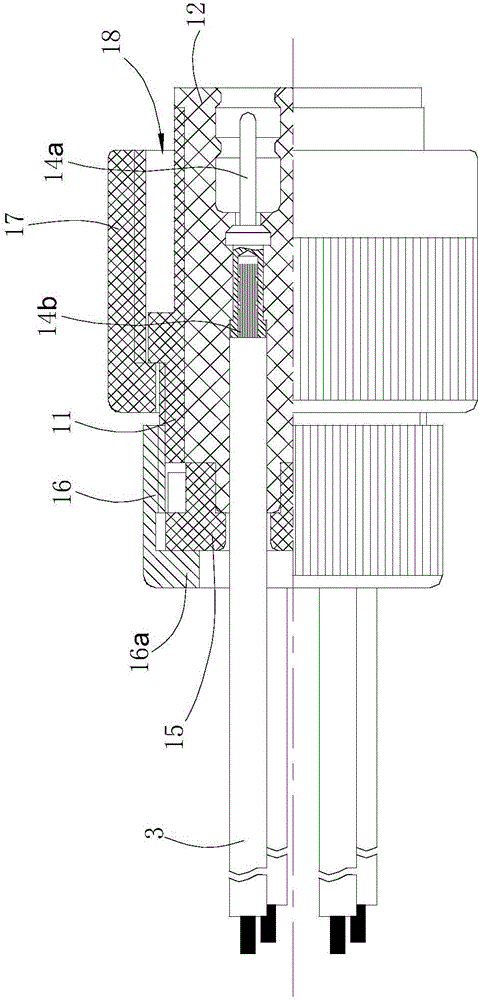

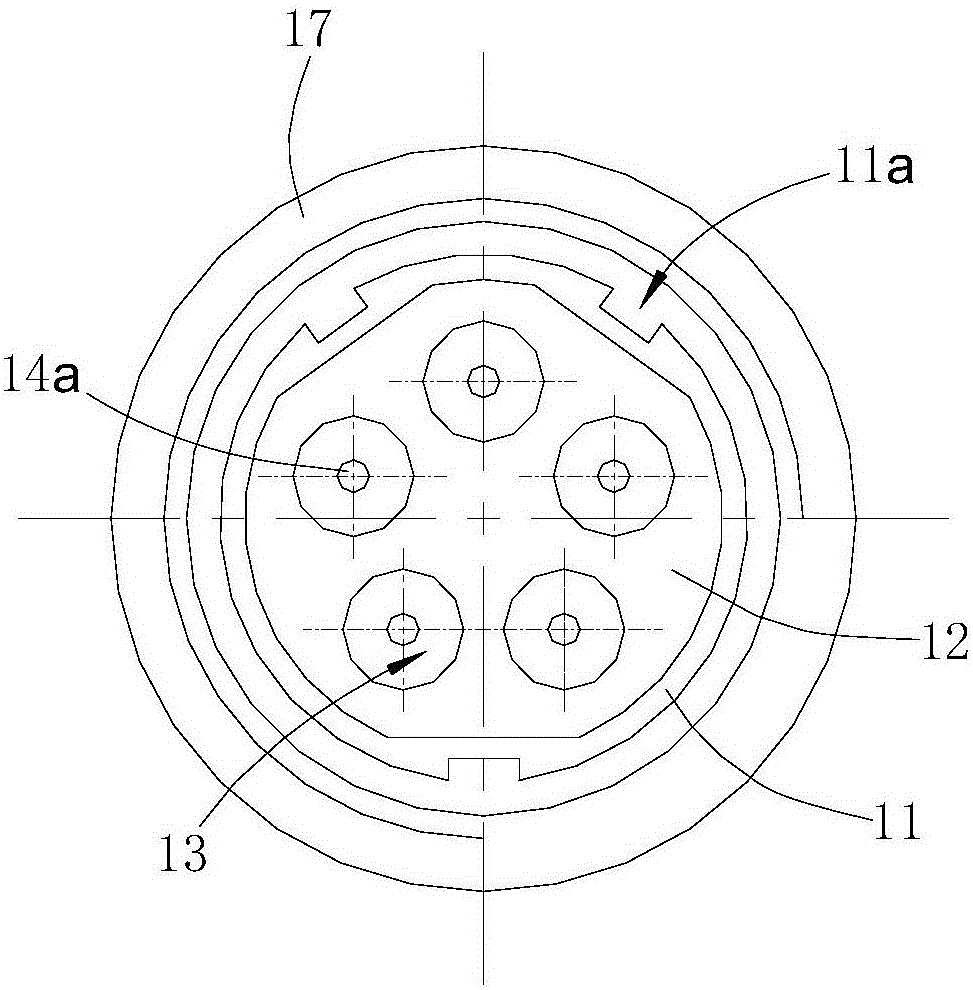

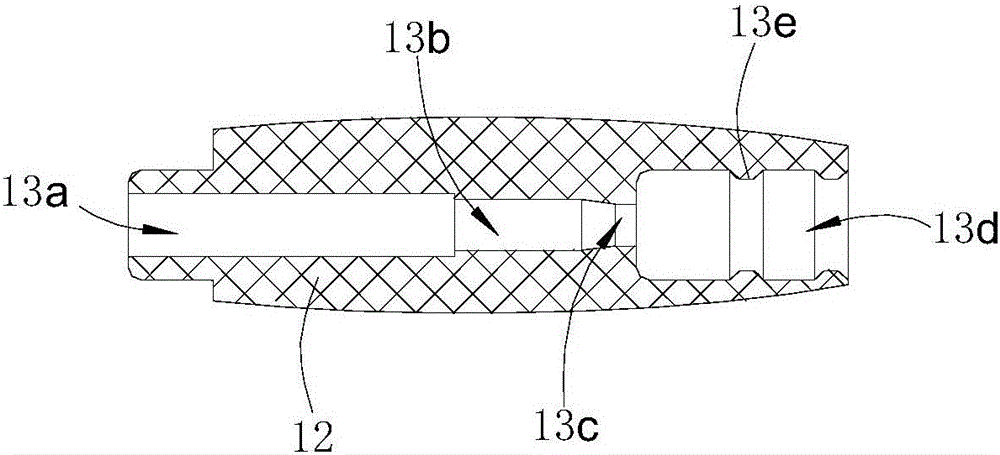

[0031] Such as Figures 1 to 6 shown

[0032] This high voltage connector consists of a socket and a plug.

[0033] The plug includes a plug housing 11 , a plug mounting plate 12 , a plug pressing plate 15 , five groups of pin assemblies, and a connecting sleeve 17 .

[0034] The plug housing 11 is generally in the shape of a short sleeve. There are three key grooves 11a on the rear outer wall of the plug housing 11. The direction of the three key grooves 11a is consistent with the axial direction of the plug housing 11. The three key grooves 11a are along the The axes of 11 are arranged circumferentially, but not evenly distributed, and the cross-sectional shape of the inner hole of the plug housing 11 is non-circular (in this embodiment, the cross-sectional shape of the inner hole of the plug housing 11 is circular and three circles are missing), The wall thickness of the area at the front of the plug housing 11 corresponding to the position of the keyway 11a of the plug h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com