Heating furnace with coil pipes capable of being pulled away

A technology for heating furnaces and coils, applied to lighting and heating equipment, furnaces, tubular components, etc., can solve the problems of inability to guarantee the quality of repaired lining, poor construction environment and construction equipment, and inability to ensure thermal efficiency of cracking furnaces, etc., and meet production conditions And the effect of product quality improvement, guaranteed construction period, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

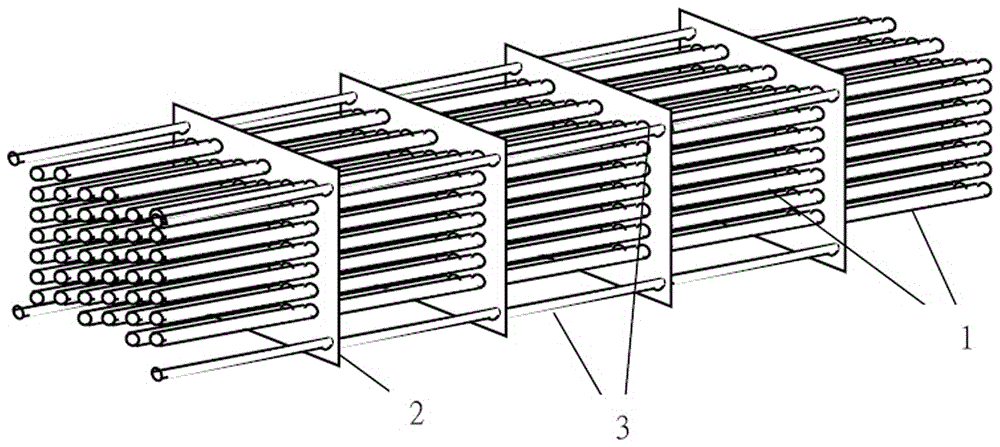

[0047] One of the heating furnaces with detachable coils in this embodiment, the heating furnace is assembled from several heat exchange coil modules, where the heat exchange coil modules refer to figure 1 and Figure 7 As shown, the heat exchange coil module includes furnace walls 16 on both sides, top beams 17, bottom beams 18, elbow boxes arranged at both ends of the furnace wall 16 and coil pipes arranged in the furnace wall 16. The coil pipes are composed of several The tube plate 2, furnace tube 1, elbow, flange short tube and header (not shown in the figure) are connected and assembled by welding. The furnace tube 1 is installed in the tube hole 13 on the tube plate, and the coil tube passes The legs on the plate 2 are supported on the lugs 15 inside the furnace wall 16, figure 1 The middle coil is a coil welded together, Figure 7 The middle coil is composed of three-component coils, and the coils can be withdrawn or pushed in whole or in part from the furnace wall 1...

Embodiment 2

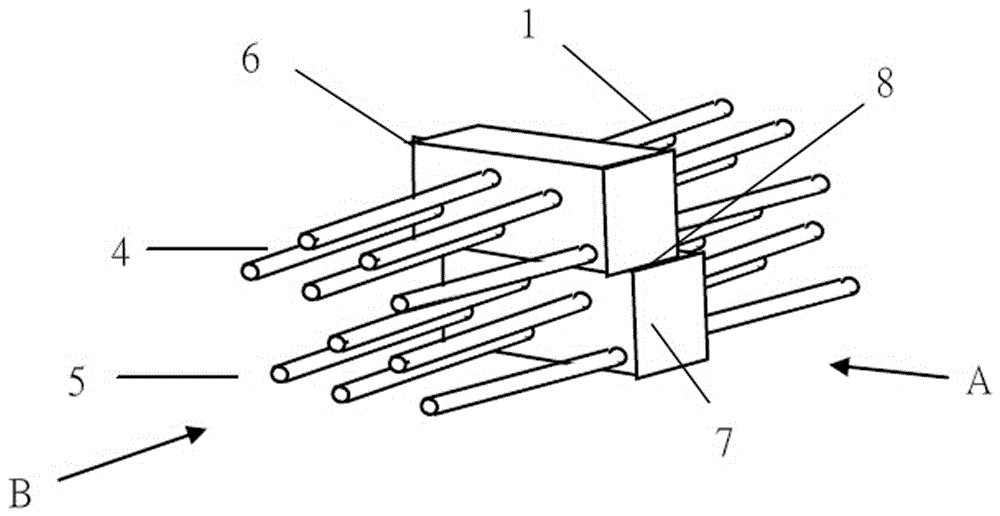

[0050] The second specific implementation mode of a heating furnace with detachable coil tubes in this embodiment, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment are adopted in embodiment 1 explanation, and will not repeat them here. The difference between this embodiment and embodiment 1 is that, see figure 2 As shown, the coil is composed of two sets of coil stacks. The tube plate 6 of the first sub-coil 4 and the tube plate 7 of the second sub-coil 5 form a sliding pair 8, which is a sliding connection, and the coil can be integrated Withdraw or advance from the furnace wall, or part of the sub-coil can be withdrawn or advanced from the furnace wall. The coil is further divided into two sub-coils to reduce weight and facilitate pulling or pushing the coil from one end of the module.

Embodiment 3

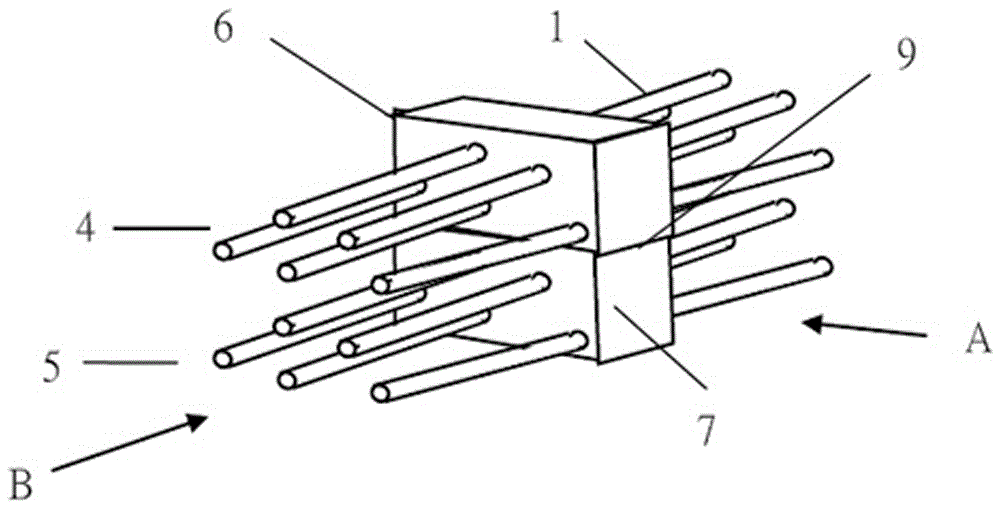

[0052] The third specific implementation of a heating furnace with detachable coil tubes in this embodiment, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment are adopted in embodiment 1 explanation, and will not repeat them here. The difference between this embodiment and embodiment 1 is that, see image 3 As shown, the coil is composed of two sets of component coil stacks, and the contact surface between the tube sheets of the two component coils is a fixed surface 9, which is a fixed connection, and the coil can be pulled out or pushed in from the furnace wall as a whole. The coil is further divided into two sub-coils, which is convenient for transportation, reduces weight, and is convenient for pulling or pushing the coil from one end of the module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com