Method for reinforcing concrete structure through embedded wet and sticky FRP strips and component of method

A concrete structure, embedded technology, applied in building construction, building maintenance, construction and other directions, can solve the problem of weakening carbon fiber slats, FRP sheet accidental wear, impact, fire, and high requirements for the flatness of the concrete bonding interface. Achieve the effect of reducing wear, convenient construction and low flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

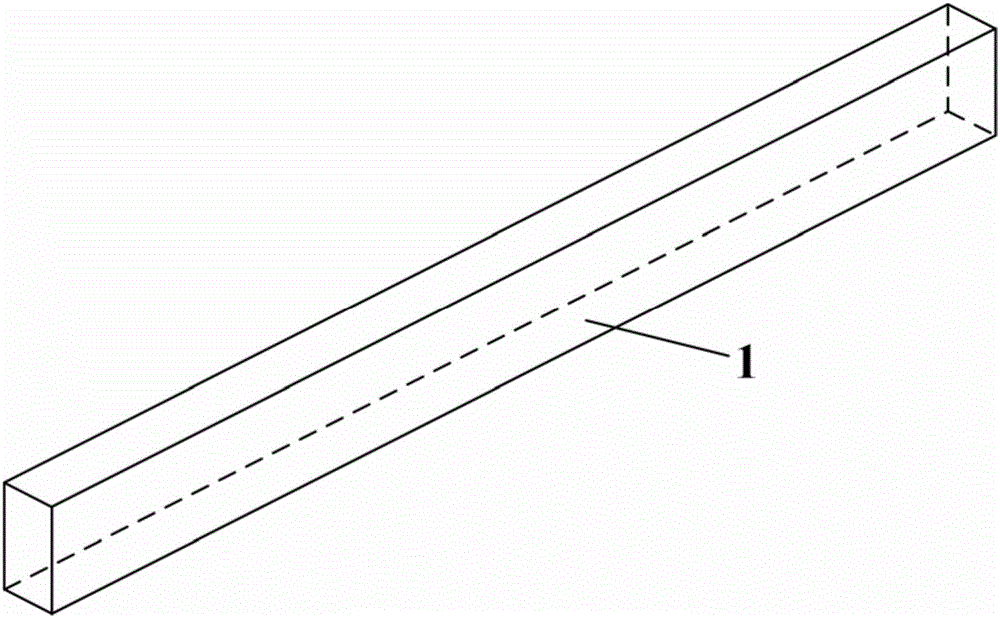

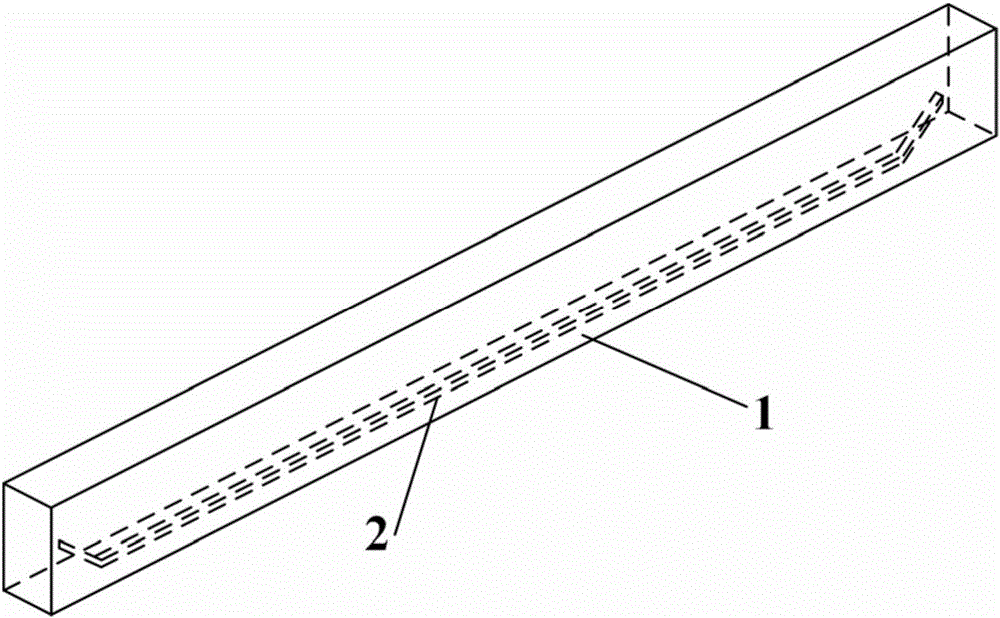

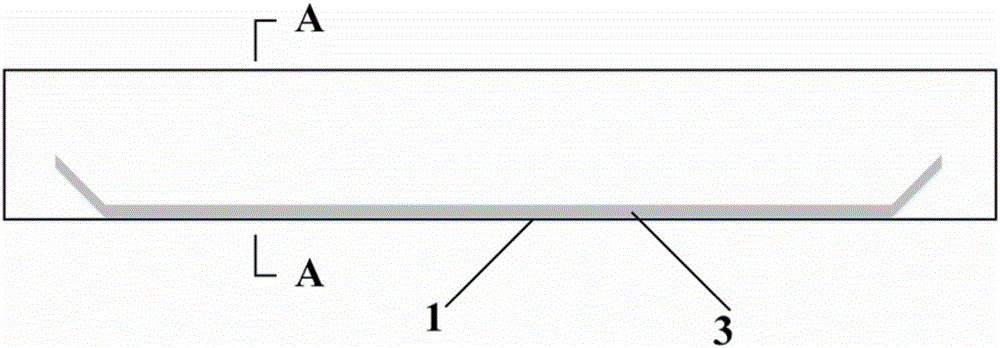

[0060] Such as Figure 1-4 , Picture 9 As shown, this embodiment provides the use of embedded wet-bonded FRP strips for bending reinforcement of the reinforced concrete structure 1, and the implementation steps include:

[0061] (1) A trench 2 is opened on the bottom surface of the concrete structure 1 to be reinforced. The trench 2 has a depth of 25 mm and a width of 12 mm. (2) Rinse the groove 2 with high-pressure water, and after the groove 2 is left to dry for at least one day, blow it with an air pump with a pressure of about 1.7 MPa to ensure that the groove 2 is clean and dry. (3) Use a glue gun to inject the adhesive into the groove 2, and the dosage is limited to a slight overflow of the groove. (4) Brush the surface of the FRP strip 3 with an adhesive that is the same as or compatible with the adhesive poured in the groove 2 and make it brush to fully wet the FRP strip 3. (5) Except for anchoring or adapting to the surface shape of the structure, the FRP strip 3 shoul...

Embodiment 2

[0063] Such as Figure 5-8 , Picture 9 As shown, this embodiment provides the use of embedded wet-bonded FRP strips for shear reinforcement of the reinforced concrete structure 1, and the implementation steps include:

[0064] (1) A number of trenches 2 are opened on the surface (including the ground, top and side surfaces) of the concrete structure 1 to be reinforced. The trenches 2 are 25mm deep and 12mm wide. The bottom trenches 2 or When the top groove 2 transitions to the side groove 2, a circular arc with a radius of 25 mm is used for transition. (2) Rinse the groove 2 with high-pressure water, and blow the groove 2 with an air pump with an air pressure of about 1.7 MPa after being dried for at least one day to ensure that the groove 2 is clean and dry. (3) Use a glue gun to inject the adhesive into the groove 2, and the dosage is limited to a slight overflow of the groove. (4) Brush the surface of the FRP strip 3 with an infiltrating adhesive that is the same as or compa...

Embodiment 3

[0066] This embodiment provides a component obtained by using the reinforcement method of the first embodiment. Such as Figure 1-4 , Picture 9 As shown, it includes a concrete structure 1 and an FRP strip 3. A groove 2 is provided on the surface of the concrete structure 1. The groove 2 is embedded with an FRP strip 3, and the FRP strip 3 is bonded The agent is embedded in the groove 1, the FRP strip 3 is woven from long fiber filaments, and the cross section of the FRP strip 3 is rectangular. Among them, the concrete structure 1 has a clear span of 4000 mm, a cross-sectional height of 450 mm, and a cross-sectional width of 200 mm. The FRP strip 3 has a thickness of 4 mm and a width of 25 mm, and the groove 2 has a width of 12 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com