Secondary speed reduction barrier gate machine core transmission mechanism with transverse motor

A two-stage deceleration, transverse motor technology, applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of complex overall structure, affecting operation, occupying too much space, etc., to reduce the installation of end caps, avoid power Loss, the effect of fast transmission response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

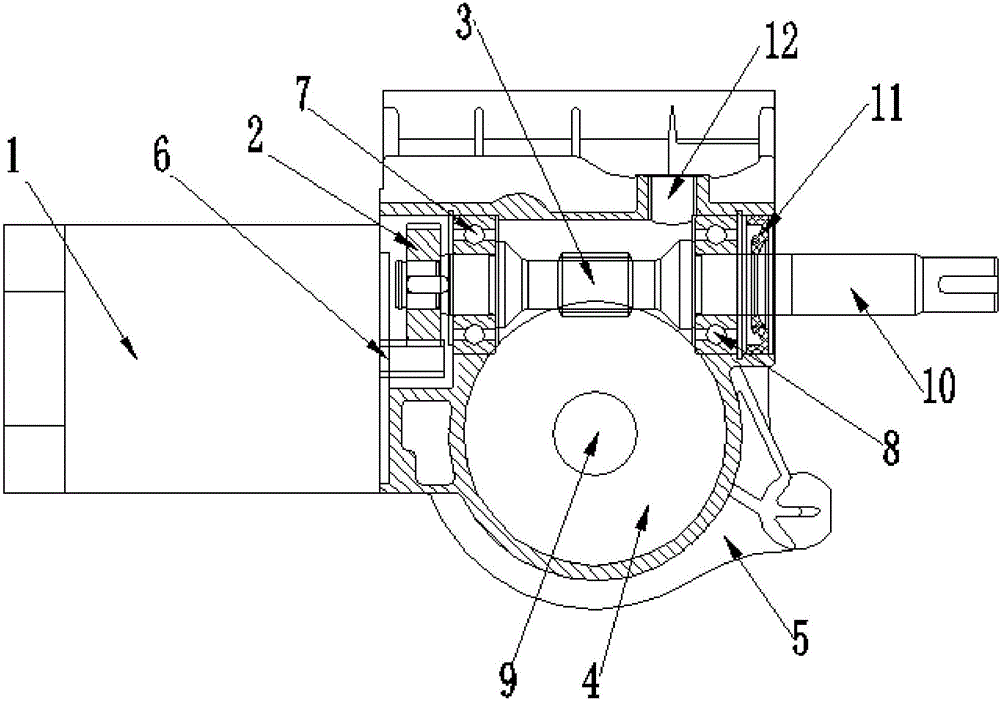

[0015] see figure 1 , The transmission mechanism of the horizontal motor two-stage deceleration gate movement provided by this embodiment includes a motor 1 , a transmission gear 2 , a worm 3 , a turbine 4 and a reduction box 5 . The motor 1 is arranged on the side of the reduction box 5, and the transmission gear 2, the worm 3 and the worm gear 4 are arranged inside the reduction box 5; wherein, the motor 1 is arranged laterally, and the output shaft of the motor 1 is connected to the reduction gear through the reduction gear. The transmission gear 2 is matched (here, it should be noted that the output shaft of the motor cooperates with the transmission gear through the reduction gear, which can be equipped with a reduction gear on the output shaft to cooperate with the transmission gear, or the output shaft of the motor 6 The end itself is a reduction gear structure, that is, an integral structure, and then cooperates with the transmission gear 2. This is the method adopted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com