Processing of Alpha/Beta Titanium Alloys

A technology of β titanium alloy and thermal processing, which is applied in the field of producing high-strength α/β titanium alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Billets from a 5.0 inch diameter cylindrical alloy having surface Average chemical composition (excluding incidental impurities) presented in 2.

[0079] Table 2

[0080] heating

Al

V

Fe

O

N

C

Ti

X

4.36

2.48

1.28

0.272

0.005

0.010

balance

Y

4.10

2.31

1.62

0.187

0.004

0.007

balance

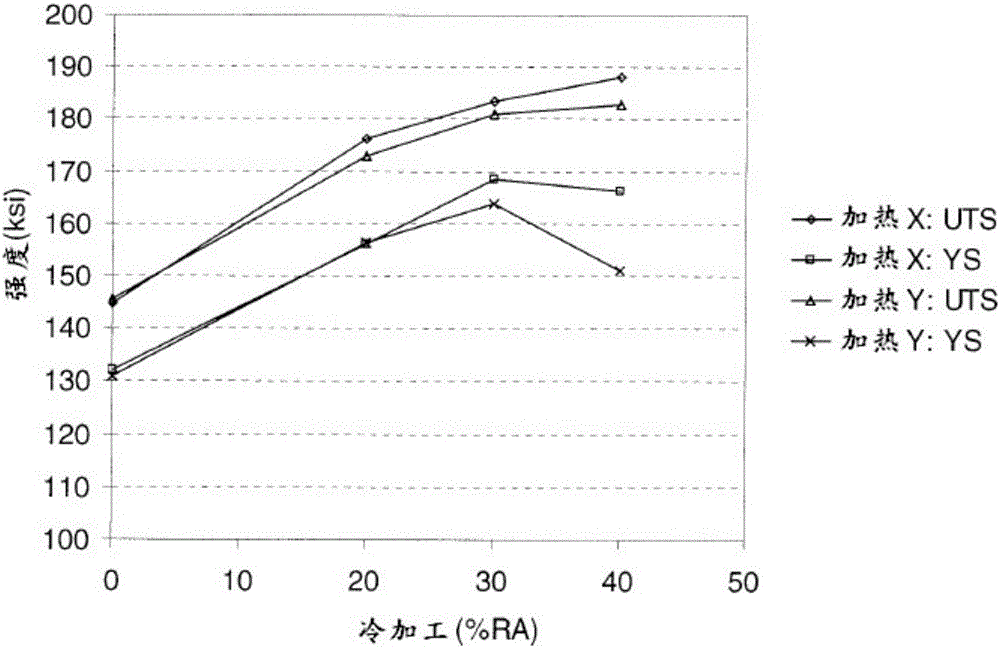

[0081] The 1.0 inch round bars were annealed at 1275°F for 1 hour and air cooled to ambient temperature. The annealed rod was cold worked at ambient temperature using a drawing operation to reduce the diameter of the rod. The amount of cold work performed on the rod during the cold drawing operation is quantified as the percent shrinkage of the circular cross-sectional area of the round rod during cold drawing. The percent cold work achieved was a reduction of area (RA) of 20%, 30% or 40%. For a reduction of area of 20%, the drawing operation was performed by a single stretch, and for a r...

Embodiment 2

[0087] A 5 inch diameter cylindrical billet heated X (beta transus 1790°F) having the average chemical composition presented in Table 1 was thermomechanically worked as described in Example 1 to form a , 30% or 40% reduction of area of the round bar. After cold drawing, the rods were directly aged using one of the aging cycles presented in Table 4, followed by air cooling to ambient temperature.

[0088] Table 4

[0089] Aging temperature (°F)

Aging time (hours)

850

1.00

850

8.00

925

4.50

975

2.75

975

4.50

975

6.25

1100

1.00

1100

8.00

[0090] The ultimate tensile strength, yield strength and elongation of each drawn and aged bar were measured at ambient temperature. image 3 The raw data are presented in and in Figure 4 and Table 5 presents the averaged data.

[0091] table 5

[0092]

[0093]Cold drawn and aged alloys exhibit a range of mechanical properties depending o...

Embodiment 3

[0096] Cold drawn round bars having the properties presented in Table 1 were subjected to double shear testing according to NASM 1312-13 (Society of Aerospace Industries, February 1, 2003, which is incorporated herein by reference). The chemical composition of the heating X, the diameter of 0.75 inches and was processed to a reduction of area of 40% during the drawing operation as described in Examples 1 and 2. Double shear testing provided an evaluation of the suitability of this combination of chemical and thermomechanical processing of the alloy to produce high-strength fastener materials. A first set of round bars was tested in the as-drawn condition and a second set of round bars was tested after aging at 850°F for 1 hour and air cooling to ambient temperature (850 / 1 / AC). In Table 5 the double shear strength results are presented together with the average values of ultimate tensile strength, yield strength and elongation. The minimum specified values for these mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com