Method for reducing content of fusel oil in Xiaoqu liquor

A technology of fusel oil and Xiaoqu liquor, applied in the field of reducing the content of fusel oil in Xiaoqu liquor, can solve the problems of high fusel oil content, achieve low cost, easy operation, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

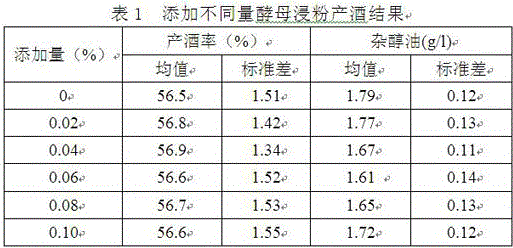

Method used

Image

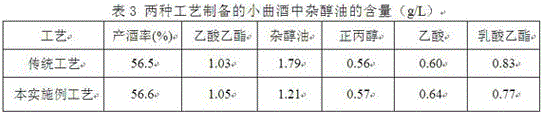

Examples

Embodiment 1

[0021] The present embodiment uses sorghum as a raw material, and a method for reducing the fusel oil content in Xiaoqu wine of the present invention comprises the following processing steps:

[0022] (1) Soaking grain: Add water at 80°C to 1000kg of sorghum, submerge the sorghum noodles for 12cm, and soak the grain for 19 hours. At this time, the water absorption rate of the sorghum is 40-45%. After the sorghum grains are evenly soaked, the foam is released food and water;

[0023] (2) Initial steaming: the above-mentioned soaked grains are initially steamed, and the initial steaming time is 60 minutes;

[0024] (3) Stewed grains: Add 85°C stewed grain water to the first steamed sorghum until the sorghum noodles are soaked for 13cm, turn the sorghum while adding water, so that the sorghum is evenly dispersed, stew the grains for 50 minutes, and release the excess after the simmering is done. stewed grain water;

[0025] (4) Continued steaming: Continue steaming the above-me...

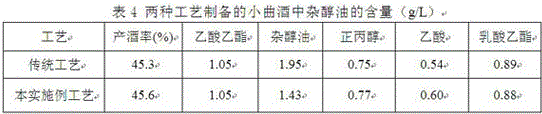

Embodiment 2

[0039] The present embodiment takes corn as raw material, and a kind of method for reducing fusel oil content in Xiaoqu liquor of the present invention comprises the following process steps:

[0040] (1) Soaking grain: add water at 78°C to 1000kg of corn, the water will cover 15cm of corn flour, and soak the grain for 20 hours. At this time, the water absorption rate of the corn is 40-45%. After soaking the corn kernels thoroughly, release the soaked grain water;

[0041] (2) Initial steaming: Initially steam the above-mentioned soaked grains, and the initial steaming time is 65 minutes;

[0042] (3) Stewed grains: Add 90°C stewed grains water to the steamed corn until the corn flour is soaked by 10cm, turn the corns while adding water to make the corns spread evenly, stew the grains for 60 minutes, and release the excess stewed grains after stewing Food and water;

[0043] (4) Continued steaming: Continue steaming the above-mentioned stewed corn, wait for the steam to pass ...

Embodiment 3

[0053] The present embodiment takes wheat as raw material, and a kind of method for reducing fusel oil content in Xiaoqu wine of the present invention comprises the following process steps:

[0054] (1) Soaking grain: Add water at 82°C to 1000kg of wheat, submerge the wheat flour by 10cm, and soak the grain for 18 hours. At this time, the water absorption rate of wheat is 40-45%. Food and water;

[0055] (2) Initial steaming: Initially steam the above-mentioned soaked grains, and the initial steaming time is 35 minutes;

[0056] (3) Stewed grains: Add 80°C stewed grains water to the steamed wheat until the wheat noodles are soaked by 10cm, stir the wheat while adding water to make the wheat spread evenly, stew the grains for 30 minutes, and release the excess after stewing braised grain water;

[0057] (4) Continued steaming: Continue steaming the above-mentioned stewed wheat, wait until the steam passes through the grain layer evenly, drain the condensed water at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com