Aqueous cold zinc spraying coating and preparation method thereof

A cold spray zinc, water-based technology, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor anti-corrosion performance and complicated construction, and achieve good recoatability, long-term anti-corrosion ability, and good repair. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

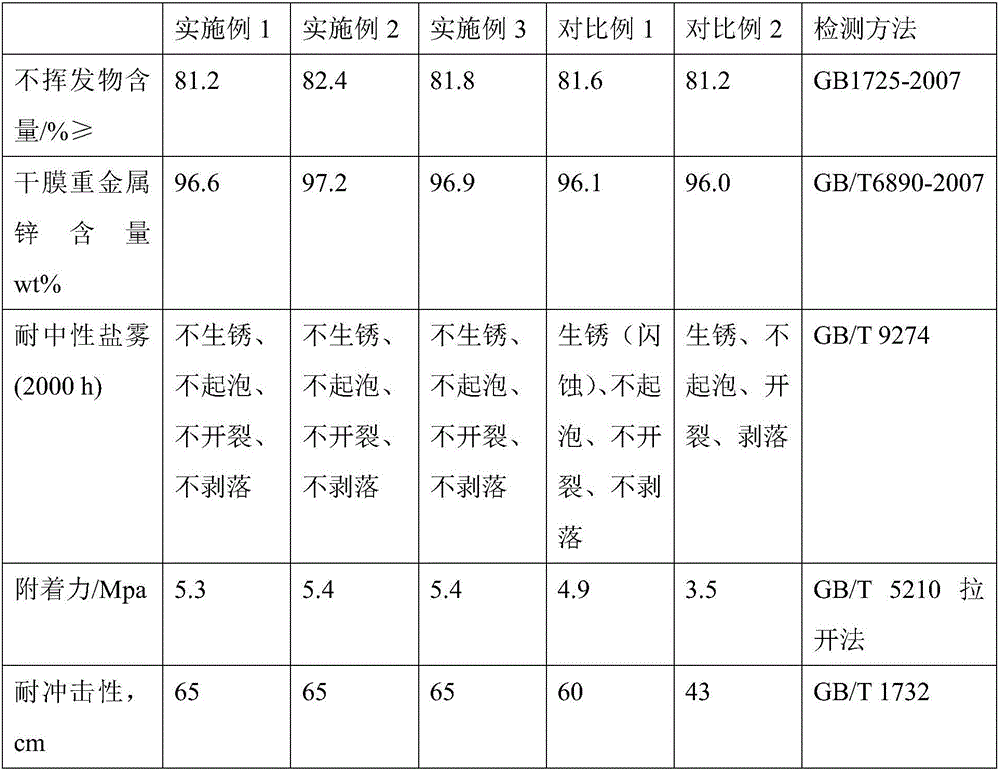

Examples

Embodiment 1

[0035] The preparation method of water-based cold spray zinc paint, comprises the following steps:

[0036] Weigh 12kg of water-based epoxy-modified polyurethane resin, 0.2kg of fumed silica, 1kg of polyamide dendrimers, and 3kg of water, add them to the reaction kettle, start the stirrer to stir at 800r / min for 20min, and then stir at 200r / min Slowly add 84kg of water-based zinc powder at a rate of 50kg / min at a rotating speed, increase the rotating speed to 800r / min and continue stirring for 30min after adding, and filter and pack with a 200-mesh filter screen to obtain the water-based cold spray zinc coating.

Embodiment 2

[0038] The preparation method of water-based cold spray zinc paint, comprises the following steps:

[0039] Weigh 10kg of water-based epoxy-modified polyurethane resin, 0.1kg of fumed silica, 1.0kg of polyamide dendrimers, and 3kg of water, add them to the reaction kettle, start the mixer to stir at 800r / min for 20min, then stir at 200r / min Slowly add 86kg of water-based zinc powder at a rate of 50kg / min under the rotating speed of 50kg / min, after adding, increase the rotating speed to 800r / min and continue to stir for 30min, and adopt 200 mesh filter screens to filter and pack to obtain the water-based cold spray zinc coating.

Embodiment 3

[0041] The preparation method of water-based cold spray zinc paint, comprises the following steps:

[0042] Weigh 10kg of water-based epoxy-modified polyurethane resin, 0.1kg of fumed silica, 2kg of polyamide dendrimers, and 4kg of water, add them to the reaction kettle, start the mixer to stir at 800r / min for 20min, and then stir at 200r / min Slowly add 84kg of water-based zinc powder at a rate of 50kg / min at a rotating speed, increase the rotating speed to 800r / min and continue stirring for 30min after adding, and filter and pack with a 200-mesh filter screen to obtain the water-based cold spray zinc coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com