tire tread structure

A technology for tire tread and crown, applied in special tires, tire parts, transportation and packaging, etc., can solve the problem that the size of the crown rubber, the base rubber or the lower layer rubber cannot be completely produced according to the construction, the tread groove bottom cracks, etc. Early shoulder gap and other problems, to avoid hidden quality problems, reduce shoulder gap problems, and reduce heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

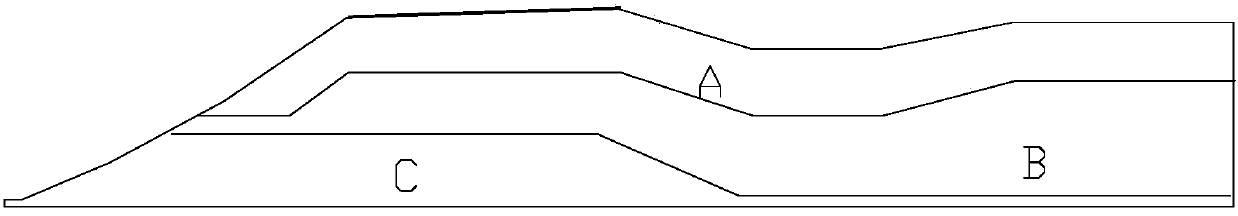

[0016] The thickness of the upper crown rubber A is 7 mm, the thickness of the lower crown rubber B is 10 mm, the thickness of the base of the base rubber C is 4 mm, and the thickness of the bottom rubber of the base rubber C is 3 mm.

[0017] The upper crown rubber A adopts a high wear-resistant rubber material, and the upper crown rubber A includes the following components, and the proportions of the components are calculated in parts by weight: 70 parts of smoked sheet rubber RSS3, 25 parts of butadiene rubber BR9000, 5 parts of polyurethane rubber, 48 parts of carbon black N134, 3.0 parts of zinc oxide, 1.5 parts of stearic acid, 4.0 parts of anti-aging agent, 1.0 part of sulfur, 1.2 parts of accelerator NS, 0.1 part of anti-scorch agent CTP.

[0018] The lower crown rubber B needs to take into account both wear resistance and low heat generation. Generally, carbon black with a prefix of "2" such as carbon black N234 is used. The lower crown rubber B includes the following...

Embodiment 2

[0021] The thickness of the upper crown glue A is 8mm, the thickness of the lower crown glue B is 12mm, the thickness of the base glue C is 5mm, and the thickness of the base glue C of the base glue C is 4mm.

[0022] The upper crown rubber A adopts a high wear-resistant rubber material. The upper crown rubber A includes the following components, and the proportions of the components are calculated in parts by weight: 100 parts of smoked sheet rubber RSS3, 52 parts of carbon black N103, 3.5 parts of zinc oxide, 2.0 parts of Parts of stearic acid, 5.0 parts of anti-aging agent, 1.2 parts of sulfur, 1.5 parts of accelerator NS, 0.3 parts of anti-scorch agent CTP.

[0023] The lower crown rubber B needs to take into account both wear resistance and low heat generation. Generally, carbon black with a prefix of "2" such as carbon black N234 is used. The lower crown rubber B includes the following components, the proportions of which are in parts by weight: 100 parts of rubber SCR5,...

Embodiment 3

[0026] The thickness of the upper crown rubber A is 7.5 mm, the thickness of the lower crown rubber B is 11 mm, the thickness of the base of the base rubber C is 4.5 mm, and the thickness of the bottom rubber of the base rubber C is 3.5 mm.

[0027] The upper crown rubber A adopts a high wear-resistant rubber material. The upper crown rubber A includes the following components, and the proportions of the components are calculated in parts by weight: 80 parts of smoked sheet rubber RSS3, 10 parts of butadiene rubber BR9000, 2 parts of polyurethane rubber, 50 parts of carbon black N134, 3.4 parts of zinc oxide, 1.6 parts of stearic acid, 4.5 parts of anti-aging agent, 1.1 parts of sulfur, 1.4 parts of accelerator NS, 0.2 parts of anti-scorch agent CTP.

[0028] The lower crown rubber B needs to take into account both wear resistance and low heat generation. Generally, carbon black with a prefix of "2" such as carbon black N234 is used. The lower crown rubber B includes the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com