Sports venue track material

A technology for sports and venues, applied in the field of track materials for sports venues, can solve the problems of incomplete improvement of the rebound rate, tensile strength and elongation at break of the plastic track, and restrict the performance of the plastic track, and achieve superior flame retardancy , high rebound rate, and the effect of improving product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

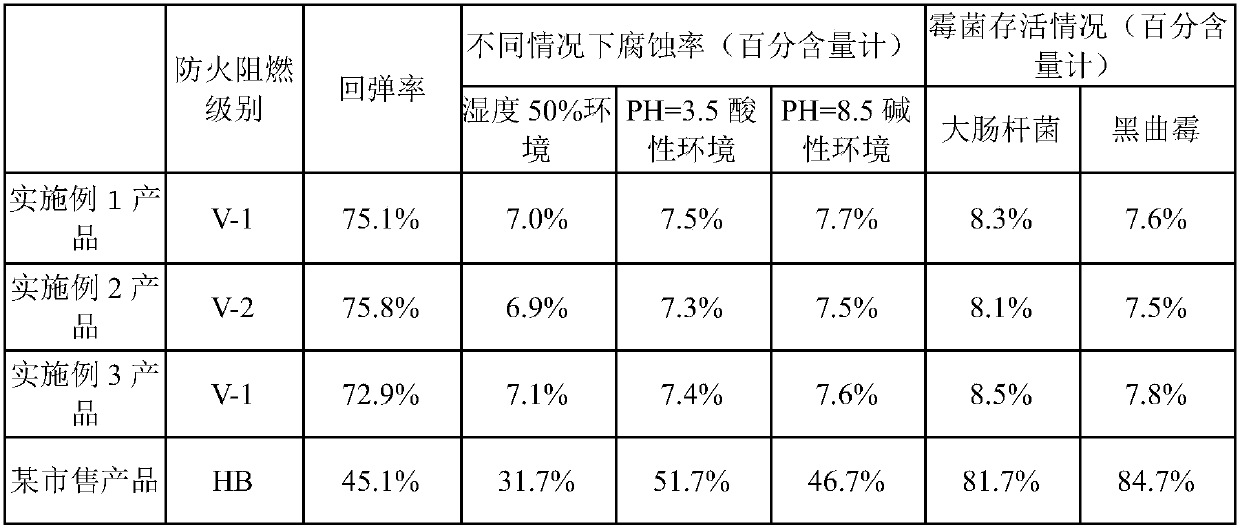

Examples

Embodiment 1

[0016] The sports track material in this embodiment consists of the following components in parts by mass: 18 parts of phenol resin, 20 parts of ammonium polyphosphate, 16 parts of hexabromobenzene, 14 parts of triethylene glycol diisocaprylate, 20 parts of carbolic acid, 16 parts of talcum powder, 14 parts of octamethyl silicone oil, 20 parts of sweet potato starch, 16 parts of calcium formate, 14 parts of chromium chloride, 20 parts of metallocene, 16 parts of zirconium boride powder, 16 parts of ferric chloride Parts, 14 parts of methyl acetate, 20 parts of citronellyl formate, 16 parts of dimethylaminoethyl acrylate, 14 parts of aziridine crosslinking agent, 20 parts of p-benzoquinone dioxime, 16 parts of diaminodiphenylmethane, 14 parts of dibasic lead phthalate, 20 parts of fluoroboric acid, 16 parts of dextrin, 14 parts of sodium methacrylate, 20 parts of methanesulfonic acid, 16 parts of sodium metabisulfite, 16 parts of polymeric alcohol amine, twelve parts 16 parts o...

Embodiment 2

[0022] The sports track material in this embodiment consists of the following components in parts by mass: 20 parts of phenol resin, 22 parts of ammonium polyphosphate, 18 parts of hexabromobenzene, 16 parts of triethylene glycol diisocaprylate, 22 parts of carbolic acid, 18 parts of talcum powder, 16 parts of octamethyl silicone oil, 22 parts of sweet potato starch, 18 parts of calcium formate, 16 parts of chromium chloride, 22 parts of metallocene, 18 parts of zirconium boride powder, 18 parts of ferric chloride 16 parts of methyl acetate, 22 parts of citronellyl formate, 18 parts of dimethylaminoethyl acrylate, 16 parts of aziridine crosslinking agent, 22 parts of p-benzoquinone dioxime, 18 parts of diaminodiphenylmethane, 16 parts of dibasic lead phthalate, 22 parts of fluoroboric acid, 18 parts of dextrin, 16 parts of sodium methacrylate, 22 parts of methanesulfonic acid, 18 parts of sodium metabisulfite, 18 parts of polymeric alcohol amine, twelve parts 18 parts of calci...

Embodiment 3

[0028]The sports track material in the present embodiment is composed of the following components in parts by mass: 22 parts of phenol resin, 24 parts of ammonium polyphosphate, 20 parts of hexabromobenzene, 18 parts of triethylene glycol diisocaprylate, 24 parts of carbolic acid, 20 parts of talcum powder, 18 parts of octamethyl silicone oil, 24 parts of sweet potato starch, 20 parts of calcium formate, 18 parts of chromium chloride, 24 parts of metallocene, 20 parts of zirconium boride powder, 20 parts of ferric chloride Parts, 18 parts of methyl acetate, 24 parts of citronellyl formate, 20 parts of dimethylaminoethyl acrylate, 18 parts of aziridine crosslinking agent, 24 parts of p-benzoquinone dioxime, 20 parts of diaminodiphenylmethane, 18 parts of dibasic lead phthalate, 24 parts of fluoroboric acid, 20 parts of dextrin, 18 parts of sodium methacrylate, 24 parts of methanesulfonic acid, 20 parts of sodium metabisulfite, 20 parts of polymeric alcohol amine, twelve parts 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com