Sound-absorbing ceramic material and preparation method thereof

A ceramic material and sound-absorbing technology, applied in the field of materials, can solve problems such as many hazards, hearing loss, and depression, and achieve good effects, strong sound-absorbing ability, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

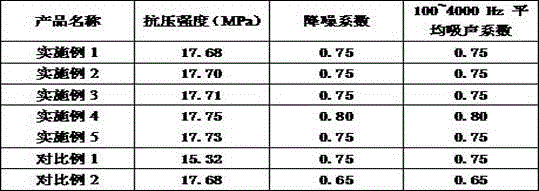

Examples

Embodiment 1

[0023] A sound-absorbing ceramic material, prepared from the following ingredients in parts by weight: 20 parts of feldspar, 10 parts of clay, 10 parts of quartz sand, 1 part of gelatin, 1 part of guar gum, 0.1 part of ascorbyl palmitate, lemon 0.1 part of sodium hexametaphosphate, 0.2 part of sodium hexametaphosphate, 0.5 part of gull gum, 1 part of sodium lauryl sulfate, 0.5 part of sodium fatty alcohol polyoxyethylene ether sulfate, 0.1 part of sodium silicate, 1 part of Tween 80, 0.5 parts of polyacrylate, 0.1 parts of cetyltrimethylammonium chloride, and 5 parts of water.

[0024] The preparation method of the above-mentioned sound-absorbing ceramic material is as follows: first grind feldspar, clay and quartz sand into powder and mix them; mix gelatin, guar gum and water, stir for 5 minutes to form a paste, and then mix all components Mix, put into the ball mill and mill at 300rpm for 30 minutes, the ball-to-material ratio is 1:1, put the ground slurry in a water bath at...

Embodiment 2

[0026] A sound-absorbing ceramic material, prepared from the following ingredients in parts by weight: 25 parts of feldspar, 15 parts of clay, 12 parts of quartz sand, 1.5 parts of gelatin, 1.3 parts of guar gum, 0.11 parts of ascorbyl palmitate, lemon 0.15 parts of sodium hexametaphosphate, 0.3 parts of sodium hexametaphosphate, 0.6 parts of gull gum, 1.2 parts of sodium lauryl sulfate, 0.6 parts of sodium fatty alcohol polyoxyethylene ether sulfate, 0.15 parts of sodium silicate, 1.2 parts of Tween 80, 0.6 parts of polyacrylate, 0.11 parts of cetyltrimethylammonium chloride, and 6 parts of water.

[0027] The preparation method of the above-mentioned sound-absorbing ceramic material is as follows: first grind feldspar, clay and quartz sand into powder and mix them; mix gelatin, guar gum and water, stir for 6 minutes to form a paste, and then mix all components Mix, put into the ball mill and mill at 330rpm for 31 minutes, the ball-to-material ratio is 1:1, put the ground slu...

Embodiment 3

[0029] A sound-absorbing ceramic material, prepared from the following ingredients in parts by weight: 30 parts of feldspar, 20 parts of clay, 15 parts of quartz sand, 2 parts of gelatin, 1.5 parts of guar gum, 0.15 parts of ascorbyl palmitate, lemon 0.2 parts of sodium hexametaphosphate, 0.35 parts of sodium hexametaphosphate, 0.75 parts of gull gum, 1.5 parts of sodium lauryl sulfate, 0.75 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 0.2 parts of sodium silicate, 1.5 parts of Tween 80, 0.75 parts of polyacrylate, 0.15 parts of cetyltrimethylammonium chloride, and 7.5 parts of water.

[0030] The preparation method of the above-mentioned sound-absorbing ceramic material is as follows: first grind feldspar, clay and quartz sand into powder and mix them; mix gelatin, guar gum and water, stir for 7.5 minutes to form a paste, and then mix all components Mix, put into the ball mill and mill at a speed of 325rpm for 33 minutes, the ball-to-material ratio is 1:1, put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com