A glass wire drawing machine and a method for drawing glass filaments using the glass wire drawing machine

A wire drawing machine and glass filament technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve problems such as restricting test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] This embodiment is used to illustrate the glass drawing machine of the present invention.

[0079] Such as figure 1 As shown, the glass drawing machine includes: a heating unit for heating the glass sample into glass liquid;

[0080] Refractory material base 1, used to send the glass sample contained in the crucible 13 to the heating unit, and optionally rotate during the process of drawing glass filaments;

[0081] Lifting traction unit for providing upward traction during drawing of glass filaments;

[0082] Adhering device 4, one end of the adhering device 4 is connected to the lifting traction unit, and the other end is connected to the heating unit for adhering the heated glass liquid;

[0083] The first control unit, the first control unit includes a laser micrometer 3, a controller 8 and a terminal control computer 9, the laser micrometer 3 is used to measure the diameter of the drawn glass filament in real time, and the glass filament The diameter measurement...

Embodiment 2-3

[0090] This example is used to illustrate the method for drawing glass of the present invention.

[0091] The glass wire drawing machine shown in Embodiment 1 is used to draw glass filaments. The specific method includes: sending the glass sample contained in the crucible 13 to the heating unit through the refractory base 1, and heating in the heating unit to obtain glass liquid , pick up the glass liquid through the connecting rod, and pull the glass filament upward through the lifting traction unit. Wherein, during the process of drawing glass filaments, the furnace 11 maintains a constant temperature of 1250° C., and the refractory base 1 and the rotating device 5 continue to rotate in opposite directions, and the rotation speeds are 5 rpm and 10 rpm, respectively.

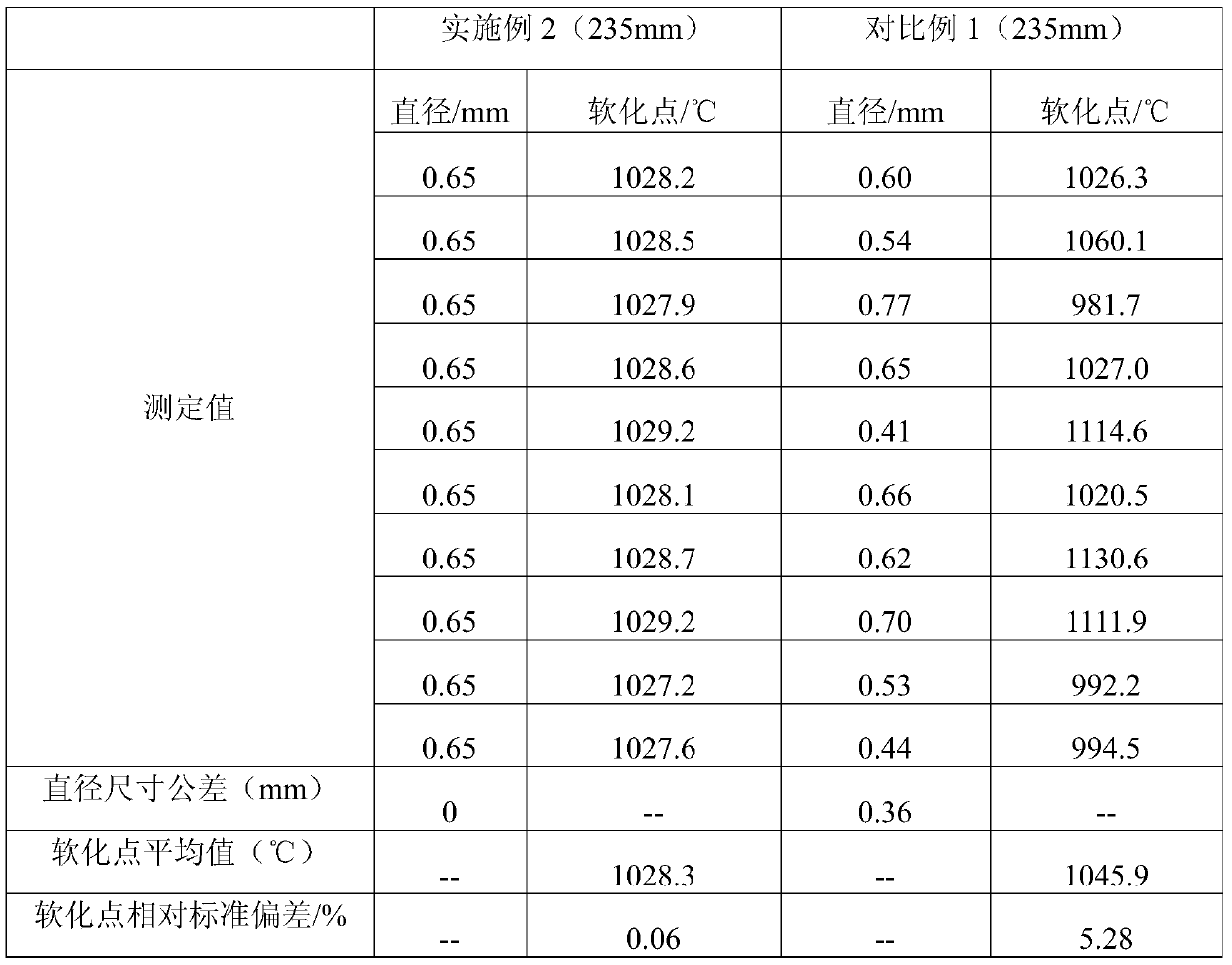

[0092] The glass filaments are drawn by controlling the following conditions to obtain glass filaments with a preset diameter of 0.65mm and a length of 235mm and glass filaments with a preset diameter of 0.65mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com